Researchers at Dongguk University in South Korea have designed a standalone liquid air energy storage (LAES) system that reportedly demonstrates significant improvements in both energy efficiency and economic performance compared to conventional LAES.

“LAES systems have attracted considerable interest in the energy storage sector due to their high energy density and geographic independence,” the research's lead author, Jinwoo Park, told pv magazine. “However, a major limitation of these systems is their relatively low round-trip efficiency compared to other energy storage systems, such as pumped hydropower storage (PHS) and compressed air energy storage (CAES).”

According to Park, although previous studies have explored improving the round-trip efficiency of LAES systems by integrating external thermal systems or using external fuels, several critical challenges persist.

“Firstly, the integration of the LAES system with external thermal systems requires adjacent thermal power plants or industrial facilities,” he added. “This requirement limits the inherent advantage of LAES systems, which is their capability for independent installation and operation. Secondly, integration with high-temperature and cryogenic heat systems, which is essential for maximizing the efficiency of LAES systems, can restrict the ability to repurpose heat for other applications, as these systems often rely on waste heat to enhance their efficiency. Finally, the use of external fuels is associated with CO2 emissions even though it can enhance the efficiency of LAES systems. Many studies overlook these associated emissions, which can lead to environmental issues and pose a significant barrier to developing sustainable energy systems.”

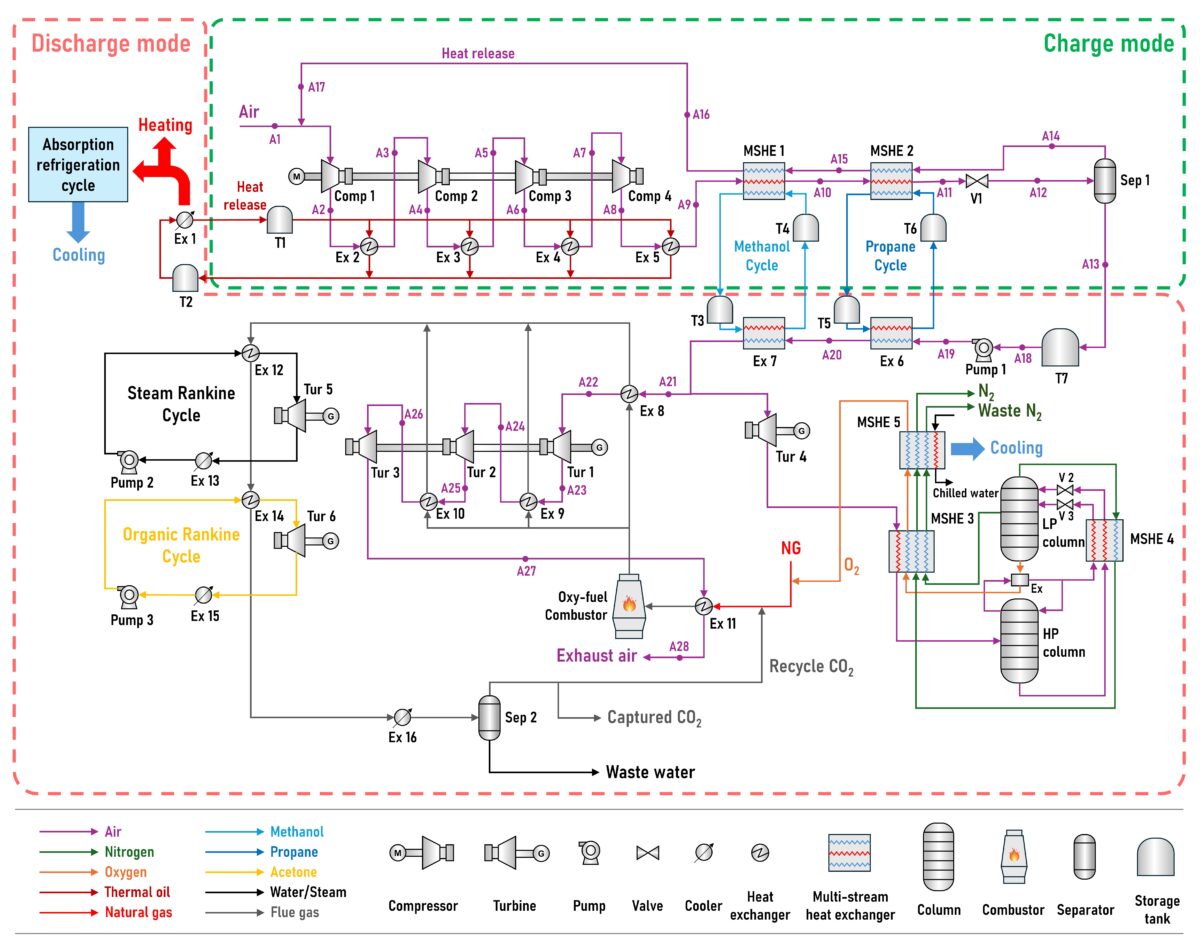

In the paper “Liquid air energy storage system with oxy-fuel combustion for clean energy supply: Comprehensive energy solutions for power, heating, cooling, and carbon capture,” published in Applied Energy, Park and his colleagues explained that the proposed system enhances efficiency by increasing power output through the generation of thermal energy using natural gas as the external fuel during energy release. The oxy-fuel combustion method is employed to generate thermal energy and a cryogenic air separation unit (ASU) separates a part of the stored liquid air into nitrogen and oxygen. The separated oxygen is then used as an oxidizing agent in the combustion reaction. Additionally, economic benefits can be obtained by selling the produced nitrogen as a by-product.

“The flue gas generated from the oxy-fuel combustion process is dehumidified to facilitate the efficient capture of CO2,” Park said. “Furthermore, the heat generated during the air compression process is stored in a thermal fluid and subsequently utilized for direct heating and cooling through the absorption refrigeration cycle (ARC).”

The research group conducted an energy and economic analysis of the system and compared its performance with that of a conventional LAES system, with both systems being designed with a capacity to store 100 MW of power. During discharge mode, the conventional system was found to generate 51.41 MW, whereas the proposed system can produce 118.19 MW, which represents a 129.9% improvement over the conventional system. Additionally, the proposed system can supply 38.64 MW for heating and 81.07 MW for cooling. Although the exergy efficiency of the proposed system is 1.32% lower than that of the conventional system, this decrease is reportedly offset by a significant improvement in its round-trip efficiency, which is 56.7% higher.

“The overall performance of the proposed system is superior, primarily because of its increased power output and improved round-trip efficiency,” Park stated. “These improvements highlight that the proposed system has the potential for more efficient energy storage and utilization, making it a promising solution for future energy requirements.”

The research team also found that the total cost of the conventional system is $553.65 million, while the total energy sales are $245.08 million, resulting in a negative cost balance. Additionally, the net present value (NPV) is negative at $258.34 million, indicating that the system is not economically viable. This is primarily due to the low efficiency of the system, according to the scientists, which said it causes the operating costs to exceed sales because of insufficient power output relative to consumption. In contrast, the proposed system has a total cost of $832.20 million and total sales of $1,708.38 million, resulting in a positive cost balance.

“The proposed system demonstrates an economically viable NPV of $636.51 million and an internal rate of return (IRR) of 25.67%,” Park added. “The total costs of the proposed system increased by 47.58% compared to the conventional system. Specifically, the capital costs increased significantly by 71.55% because of several factors: the enhanced power output of the turbines, modifications to the heat exchange system to improve efficiency, and the installation of additional equipment. The operating costs also increased by 37.01% owing to the additional use of natural gas as an external fuel. Despite these cost increases, electricity sales more than doubled because of significant improvements in system efficiency. Furthermore, additional revenue from nitrogen sales, as well as cooling and heating supplies, contributed to a remarkable 597.07 % increase in total sales.”

According to the research group, the novel system effectively addresses the limitations identified in previous studies, such as challenges

in integrating other thermal systems and using external fuels. Specifically, it overcomes the limitations of existing thermal integration methods, which rely on specific thermal power plants or industrial facilities, and resolves the CO2 emissions associated with external fuel use.

“In conclusion, the proposed LAES system represents promising technology for future sustainable energy supply and is expected to offer valuable insights for developing efficient energy systems to achieve a carbon-neutral society,” Park affirmed.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.