From pv magazine Germany

A research team at the Technical University of Munich (TUM) has developed a new method that will enable aqueous zinc-ion batteries to endure several hundred thousand charge and discharge cycles in the future.

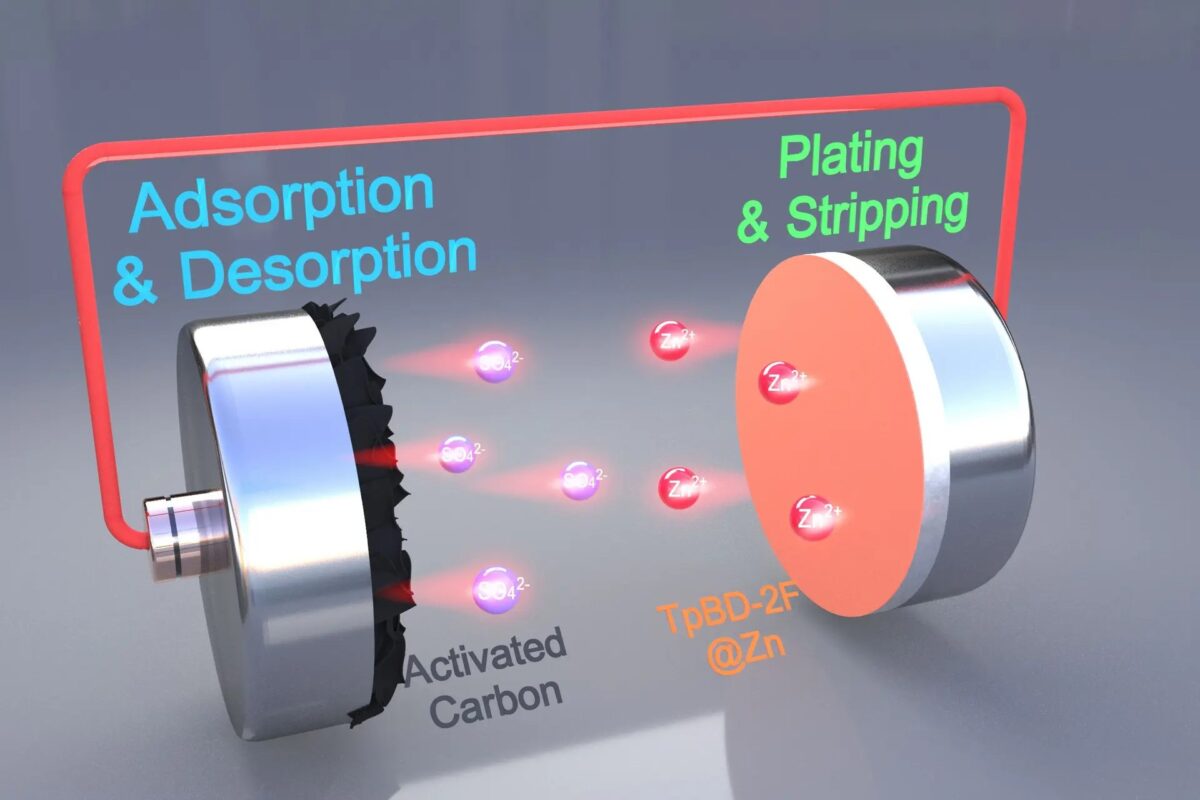

This significantly improved service life is made possible by a special protective layer for the zinc anodes of the batteries, according to a TUM statement released on Tuesday. The researchers use a porous organic polymer called TpBD-2F to form a “stable, extremely thin and highly ordered film” on the zinc anode, which allows the zinc ions to flow very efficiently through nano-channels and at the same time keeps water away from the anode. “This layer addresses previous issues such as the growth of needle-like zinc structures — known as zinc dendrites — as well as unwanted chemical side reactions that trigger hydrogen formation and corrosion,” the research team explained in the statement.

“Zinc-ion batteries with this new protective layer could replace lithium-ion batteries in large-scale energy storage applications, such as in combination with solar or wind power plants. They last longer, are safer, and zinc is both cheaper and more readily available than lithium,” said Da Lei, Ph.D. student and lead author of the research paper “Ion-Transport Kinetics and Interface Stability Augmentation of Zinc Anodes Based on Fluorinated Covalent Organic Framework Thin Films,” published in Advanced Energy Materials. Lithium remains the first choice for mobile applications like electric vehicles and portable devices, but its higher costs and environmental impact make it less attractive for large-scale energy storage.

“This is truly a spectacular research result,” added Roland A. Fischer, chair of Inorganic and Metal-Organic Chemistry at the TUM School of Natural Sciences. “We have shown that the chemical approach developed by Da Lei not only works but is also controllable. As fundamental researchers, we are primarily interested in new scientific principles — and here we have discovered one. We have already developed a first prototype in the form of a button cell. I see no reason why our findings couldn’t be translated to larger applications. Now, it's up to engineers to take up the idea and develop appropriate production processes.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.