A team in Europe aims to develop 20%-efficient metal halide perovskite prototype modules measuring over 900 cm2 with a targeted lifetime of 20 years. The consortium will use industrially compatible R2R processing. The project is funded by the Horizon Europe program, and its members include representatives from industry, universities, and research and technology organizations (RTOs).

“Flexible perovskite solar cells are being developed in many places in Europe,” Ilker Dogan, team lead energy and materials transition at Netherlands Organization for Applied Scientific (TNO), told pv magazine. “In the laboratories, an efficiency of up to 26% is already being achieved, but this is done in very controlled conditions, without taking into account operational safety and environmental impact.”

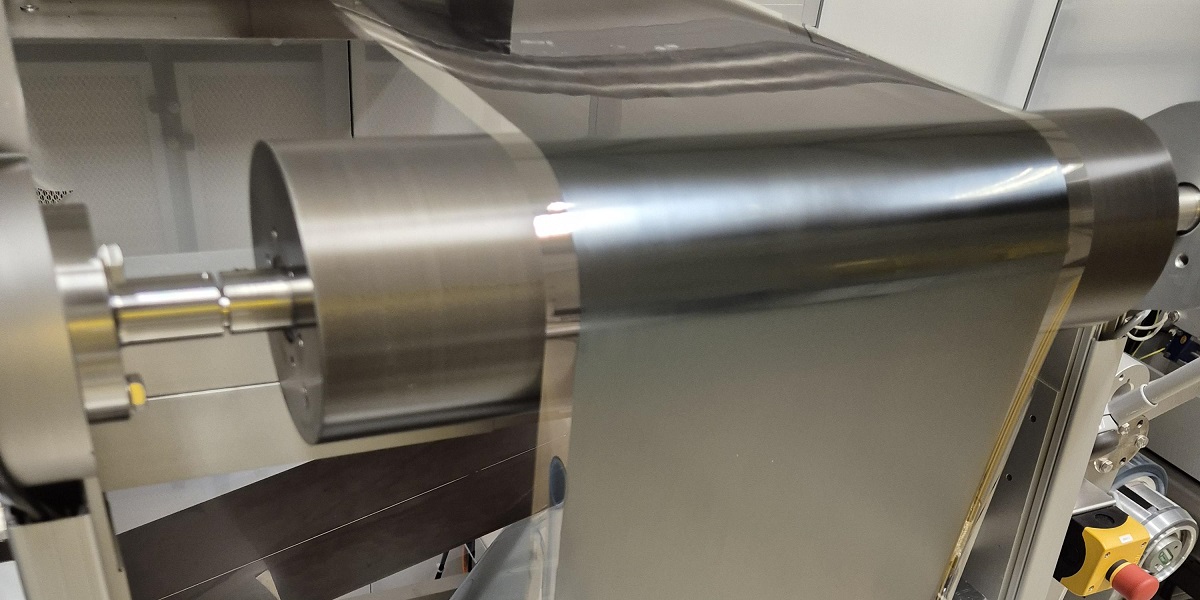

The team proposes to leverage established processes from industry, such as R2R and laser processing, as well as vacuum deposition. The researchers also aim to design perovskite modules from the start to be low carbon and environmentally sustainable.

The project acronym LUMINOSITY stands for large-area uniform industry-compatible perovskite solar cell technology. It is a four-year project that began in May with a budget of €6.9 million ($7.46 million).

“In (the) LUMINOSITY project, we demonstrate the technology in industrially relevant processing environments, bringing the technology readiness level (TRL) up to seven,” said Dogan. “We do this with a consortium that is composed of universities, RTO’s and companies, who will promote the various components of the technology to commercial level.”

The team is using an aluminum (Al) fluorinated-tin-oxide (FTO) electrode foil sourced from Hyet Solar B.V., the Netherlands. The AI/FTO is seen as superior to alternative substrates because it allows for high-temperature processes, better stability and efficiency, while maintaining material flexibility, according to Dogan.

“Most of the layers deposited in this perovskite solar cell stack are processed below 150C. In this aspect, it is compatible to most of the flexible substrates. However, the limitation of low temperature process is not a problem on the Al/FTO foil that we are using here,” Dogan explained. “The greatest challenge is to match industrial scale processing speeds with suitable solvent systems, while keeping large area uniformity and efficiency that is comparable to small scale device efficiencies.”

The project will include stability and lifetime testing, including outdoor testing, a life cycle assessment, and a techno-economic analysis.

Several applications are foreseen for the flexible large-area perovskite devices in building-integrated PV and building-applied PV. “First application areas that are envisioned is buildings, rooftops and façades,” said Dogan. “On top of that, it can be applied at utility scale and agricultural areas as well.”

Participating partners from industry include Hyet Solar B.V. from the Netherlands, Czechia-based consultancy AMIRES s.r.o, Danish material and equipment supplier Infinitypv, and two Germany-based equipment suppliers, Von Ardenne and LPKF Solarquipment.

Research groups from the following institutions are participating: TNO, TU Delft, Eindhoven University of Technology, Universiteit Hasselt, Lund University, Cyprus University of Technology (CUT), Swiss Federal Laboratories for Material Science (EMPA), Helmholtz-Zentrum Berlin für Materialien und Energie (HZB), Fraunhofer Institute for Electron Beam and Plasma Technology (FEP), Consiglio Nazionale delle Ricerche (CNR).

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.