Germany's MBJ Solutions, a PV industry equipment specialist, recently launched the MBJ Steady State Sun Simulator, designed for small perovskite module characterization, and the MBJ Light Soaking Unit, made for perovskite device aging tests and preconditioning.

The market for the MBJ Solutions equipment is international, according to Volker Biemann, MBJ solutions product manager. “We have customers all over the world but mainly Europe, US and Southeast Asia,” Biemann told pv magazine.

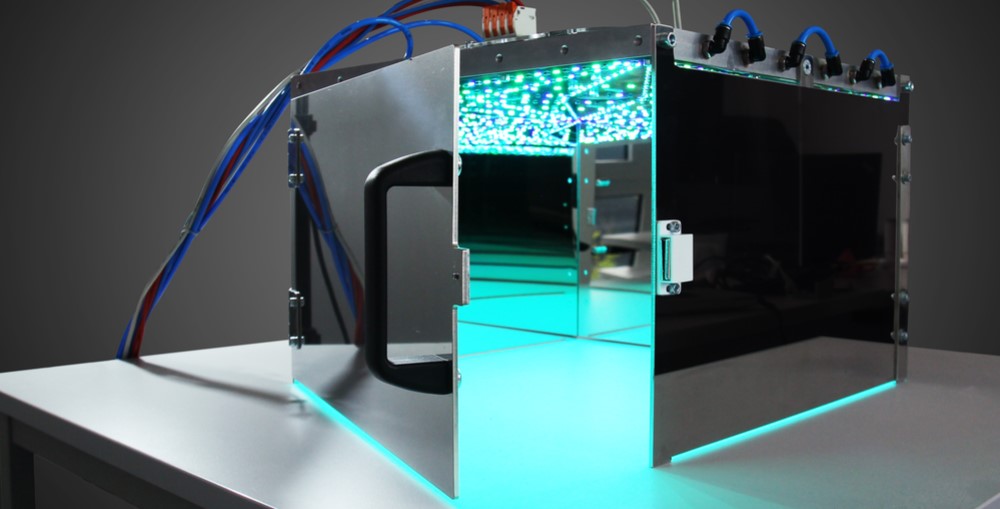

The MBJ Steady State Sun Simulator, featuring a 500 mm x 500 mm measuring area, is made for teams developing a range of device sizes, from cells to small modules. It has a continuous Class A+ sun simulator, compliant with IEC 60904-9 Ed.3. The 22-LED unit has extended ultraviolet and infrared extended spectrum. The spectral coverage and deviation are > 98% and < 24%, respectively, It is compact, with an integrated 5 megapixel electroluminescence camera.

The MBJ Light Soaking Unit can be used as a test bench for aging tests for solar cells, as well as for preconditioning in cell production before I/V measurements. The system has variable LED that can support continuous light and flash mode in a 380 mm x 380 mm measurement area. It is supported by two separately controllable LED channels. The flash time can be varied from 100 to 500 milliseconds. Each LED channel delivers 1000 W/m² at about 50% of the permissible current with a service life of > 50,000 hours.

The equipment requires minimal training, according to Biemann. “It depends on the system type but typically the operators need one day training to be able to operate and maintain the system,” he said.

MBJ Solutions also launched an upgraded version of its mobile PV module testing system this year, complete with solar-simulator and electroluminescence test support. It is made for on-site measurement of large-sized panels, for example, inspections before installing or afterwards.

Founded in 2009, MBJ Solutions develops test and measurement systems for the PV industry, including sun simulators, electroluminescence test systems, as well as insulation and ground testing equipment. Development and production are based in Germany, with a service office in Taiwan.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.