A group of scientists from Chinese solar module maker Longi has described in a new scientific paper the 27.09%-efficient heterojunction back contact (HBC) solar cell it unveiled in December 2023.

At the time, Longi only said the result was enabled through a new laser graphical process that costs less than conventional high-cost photolithography processes, without providing further details. In the new paper, the company explained that the laser patterning technique was developed by Longi itself. Furthermore, it not only provided a thorough technical description of the cell architecture, but also presented a strategy on how to improve contact resistivity, series resistance, and the design of the rear-side pattern.

The group specified that HBC solar cells have issues with carrier recombination losses and said these arise from the hole-selective contact region and polarity boundaries. “We propose solutions to these issues and establish a clear relationship between contact resistivity, series resistance, and the design of the rear-side pattern,” they added.

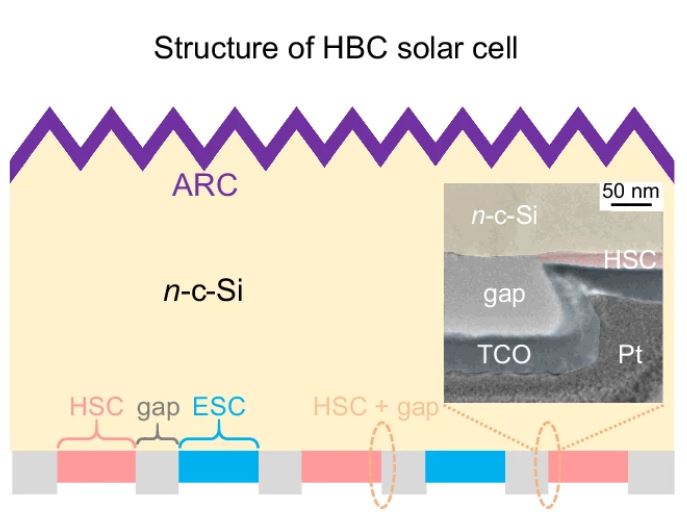

The research group built the 243.0 cm2 cell with a 200 µm-thick Longi M6 274.3 cm2 Czochralski wafer based on n-type monocrystalline silicon. The front side features anti-reflection coatings (ARC), and the rear side is divided into four regions, which are hole-selective contact (HSC), gap region, electron-selective contact (ESC), and HSC plus gap.

“We exploited amorphous silicon as passivating contact layers and laser ablation as a mass-production technology for fabricating HBC solar cells,” the academics explained. “This endows advantages including low leakage at the area near the n-p polarity boundary, low cost, low deposition difficulty, and high uniformity.”

Through laser patterning, the researchers applied a pulsed green picosecond laser to ablate the overlying i-a-Si:H/p-a-Si:H stack in the designed ESC region. The transparent conducting oxide (TCO) layer was deposited using the magnetron sputtering technique.

They also used pulsed ultra-violet picosecond laser to ablate the designed gap region to remove TCO/p-a-Si:H/i-a-Si:H stack for isolation, which they said avoids leakage channels. The silicon nitride (SiNx) layer was used to prevent the passivation performance of the i-a-Si:H/n-a-Si:H stack from being damaged.

Tested under standard illumination conditions, the device achieved a power conversion efficiency of 27.07% and an open-circuit voltage of 751 mV, with the results being confirmed by Germany's Institute for Solar Energy Research (ISFH). The open-circuit voltage value is indicated by Longi as one of the highest ever recorded at the research level for this kind of solar cell.

Their analysis also showed that the cell, like other HBC devices, suffers from electrical shading effects, as carriers for both polarities are collected on the same side, and the resulting decline in short-circuit current density. They also found, however, that these losses are slightly smaller than those seen in previous devices.

“This is primarily attributed to the additional current gain from the thicker silicon wafer and the designated illumination area used in measurements, excluding the influences of recombination and leakage at the silicon wafer edge,” they further explained.

The group also found that contact resistivity plays a pivotal role in high-efficiency HBC solar cells and said that minimizing the contact area of the HSC or ESC region was crucial to improving cell efficiency. “By optimizing the HSC region, we achieved the lowest contact resistivity using p-a-Si:H film,” it specified. “Furthermore, we determined that the contribution of contact resistivity to resistivity can be directly calculated based on the coverage area ratio.”

Looking forward, the researchers said they want to use wafer edge effects and implement “meticulous” optimization of front anti-reflection coating and rear reflector, which they believe can help the cell achieve an efficiency of up to 27.7%.

The solar cell architecture was described in “27.09%-efficiency silicon heterojunction back contact solar cell and going beyond,” published in nature communications. “The research offers multiple strategies and guidelines for optimizing structural design and resolving major contradictions within back-contact solar cells,” the group stressed.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.