Scientists from Germany's Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) and the Tarbiat Modares University (TMU) in Iran have designed a PV system for microalgae and electricity co-production.

They explained that aquaculture facilities have commonly high electricity costs accounting for approximately 40 % of their total energy costs, with around 0.5 % of global GHG emissions being attributable to aquaculture. “The cultivation of microalgae in open pond systems, when integrated with PV technology, can improve energy efficiency, and reduce water evaporation, further aligning aquaculture practices with climate change mitigation goals,” they stressed.

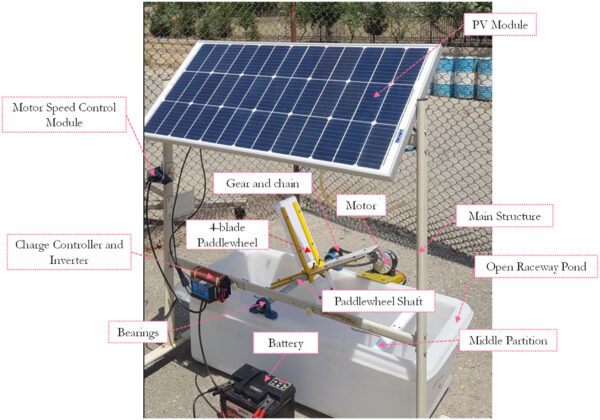

The research group described the proposed technology as a “small aquavoltaic” system consisting of an open raceway pond, a mechanical paddle wheel, a motor and power transmission system, a motor speed control circuit, a 100 W photovoltaic module, and 12-V battery with a capacity of 60 Ah, an inverter, and a 10-A charge controller.

The key element of the system, the polyethylene raceway pond, was conceived with an open design to allow access to sunlight and air. Usually, these ponds have a shallow design to reduce evaporation and contamination, as well as to favor continuous water circulation.

The academics set the optimum water depth for microalgae production in the pond at 0.3 m. “By controlling this specific water depth together with other parameters such as rotation speed and reaction time, it is possible to create favorable conditions for both microalgae production and electricity generation in the aquavoltaic system,” they further explained.

The performance of the system was assessed through a series of experimental tests conducted from May 9 to May 15, under different weather conditions. The main parameters were solar radiation, air temperature, and wind speed.

The analysis showed that the shading caused by the solar panel has a “significant” impact on controlling the temperature and pH range in the microalgae production pond. The module, however, was able to cover approximately 98.6 % of the aquaculture facility's annual electricity demand.

The team also conducted a techno-economic analysis on a system hosting the cultivation of Spirulina, blue-green algae containing vitamins, minerals, antioxidants, and proteins, and found it was able to achieve 7% lower electricity costs compared to a reference system powered by grid electricity.

“The cost of Spirulina produced with the aquavoltaic system in the fifth year was calculated at $0.4975/g at a %5 interest rate and $0.331/g at a %10 interest rate,” the scientists emphasized. “In addition, the cost per liter for Spirulina produced with the aquavoltaic system was calculated at $0.7133/g.”

The details of the system can be found in the paper “Development and experimental performance evaluation of a small-scale aquavoltaic system for microalgae production,” published in Results in Engineering. “The current study underlines that aquavoltaics could have the potential to further increase the production of microalgae and thus reduce production costs,” the researchers concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.