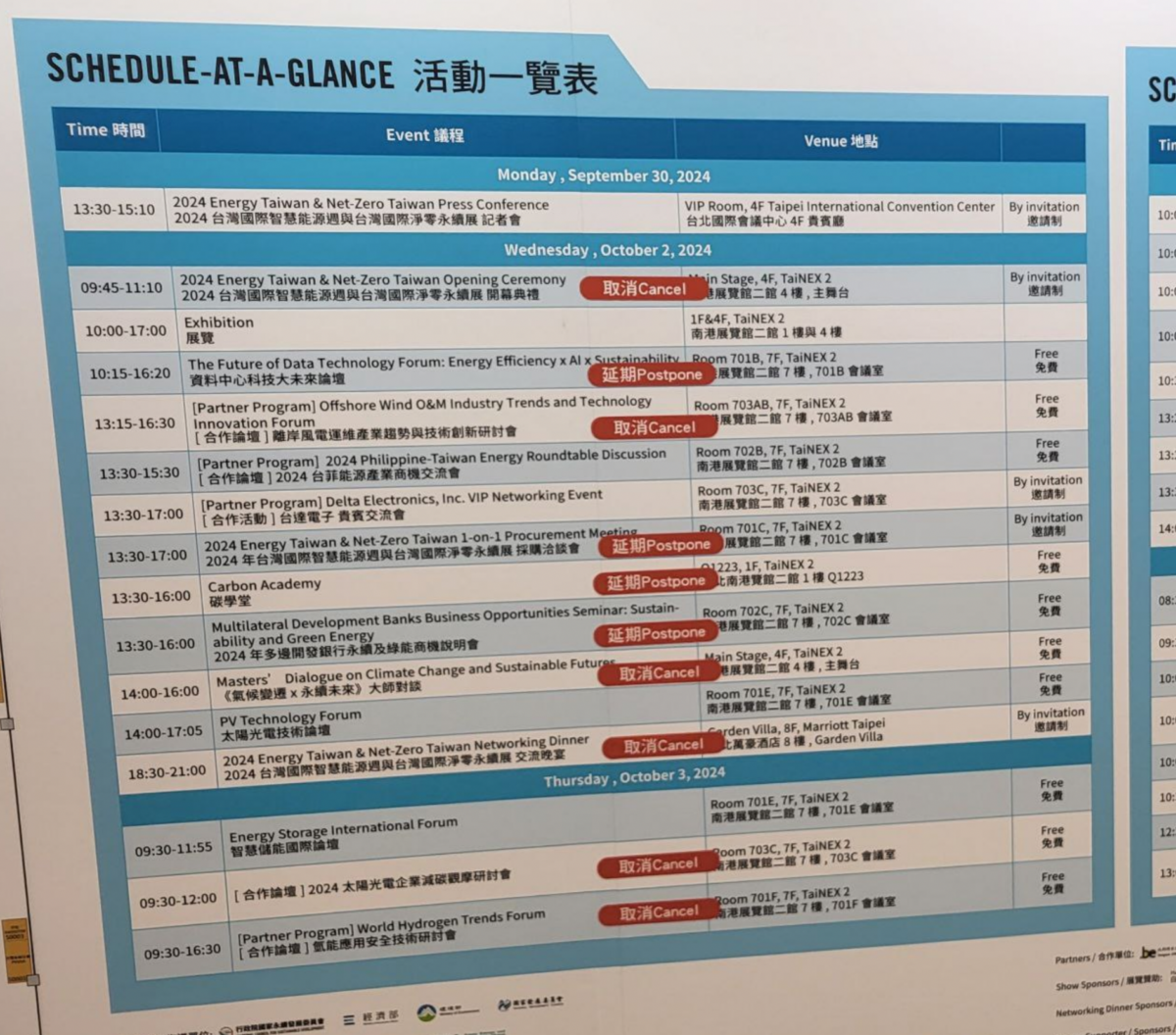

The Energy Taiwan & Net-Zero Taiwan 2024 trade show opened with a slow start, as the threat of Typhoon Krathon resulted in the cancellation of the first two days of the event in Taipei. However, Taiwanese Economic Affairs Minister Kuo Jyh-huei still held an opening press conference, unveiling a roadmap to net-zero emissions by 2050.

While the tropical cyclone battered the island’s southern coast, leaving thousands of homes without power, Taipei emerged largely unscathed, making the schedule changes regrettable. Despite these disruptions, the event showcased a dizzying range of technologies, including PV solutions, electric vehicle charging systems, and energy storage options, all aimed at transforming Taiwan's energy landscape.

“Typhoons are a very seasonal event,” said Steven Lin, product manager at Voltronic Power Technology, which specializes in uninterruptible power supplies, solar inverters, and electric vehicle chargers. “The typhoons dissipate in a matter of a few days, so it’s not really a disruption.” Lin expressed more concern over potential geopolitical impacts on operations than weather-related disruptions.

Path to zero

Taiwan aims for 20 GW of solar capacity by 2025, from about 14 GW at present, and expanding to between 40 GW and 60 GW by 2050. Companies such as TSEC Corp. are stepping up, producing tunnel oxide passivated contact (TOPCon) and passivated emitter and rear cell (PERC) solar cells and panels with an annual capacity of 1.5 GW and efficiencies up to 24.25%.

Jackson C.K. Lu, account manager for TSEC, said the company is focused on the Taiwanese market but is eyeing opportunities in the United States. He noted that the use of traceable materials compliant with US customs regulations could favorably position TSEC in the US market, but explained that it is mainly interested in supplying solar cells in the United States at this time, rather than finished modules.

The company recently launched its QUANTUM TOPCon solar modules, delivering 520 W to 540 W with up to 22.8% efficiency. Each panel features a monocrystalline TOPCon cell, measures 2,093 mm x 1,134 mm x 35 mm, and weighs 25.5 kg. The modules meet international standards, backed by a 12-year materials warranty and a 30-year linear power warranty.

Lu emphasized the industry's push for higher power outputs to reduce costs. He said current PERC panels peak at about 500 W, while TOPCon panels can reach 590 W to 600 W. He described the shift from multicrystalline to mono PERC and now to TOPCon as a “quantum leap,” with TOPCon cells averaging 25% efficiency compared to PERC’s 23.5%. The company is also developing perovskite technology.

“In Taiwan, space is limited, so most customers look for smaller panels,” Lu said, referring to TSEC’s SkyHawk panel series for rooftop applications. “But if they seek more power, we will promote our new TOPCon series.”

Motech, meanwhile, showcased innovations in building-integrated photovoltaics (BIPV) and agrivoltaics. The company’s BIPV panels produce between 350 W and 600 W, but it faces challenges in Taiwan due to limited government support and low consumer interest.

A Motech spokesperson said only about 40% of Taiwan’s land is open for solar installations – much lower than more advanced markets such as Germany. Yet the company remains optimistic about future policy changes and is pursuing floating PV projects and carports to expand its market reach.

The Motech spokesperson noted growing customer interest in BIPV, pointing to a potential new trend. However, he acknowledged the need for clearer policies, especially in comparison to Germany, which actively promotes agrivoltaics.

“We want more customers and manufacturers to push the government to change the policy for both BIPV and agri-PV,” he said.

URE Corp. – formed from the 2018 merger of Neo Solar Power (NSP), Gintech Energy, and Solartech Energy – outlined its strategic initiatives at Energy Taiwan 2024. The company said it aims to develop TOPCon solar cells with a targeted efficiency of 30% by next year, building on its current 26%. A spokesperson said URE also aims to offer business storage solutions for the commercial and industrial (C&I) sector in Europe.

URE said it will likely make the full transition to TOPCon technology by next year, while continuing some PERC production to meet ongoing commitments to existing clients. Its R&D team is also working on perovskite tandem cells.

Storage solutions

Formosa Smart Energy Tech Corp. (FSET) plans to expand the capacity of its energy storage solutions from 150 MW to 450 MW within two years through its lithium iron phosphate (LFP) batteries, to become Taiwan's largest LFP producer. The company recently completed the first 2.1 GWh of LFP cell and module production capacity in Changhua county – the largest automated facility of its kind in Taiwan. It is set to start mass production in November and the company aims to eventually expand its annual output to more than 5 GWh.

In addition, FSET plans to establish a battery recycling facility as part of a comprehensive domestic supply chain. LFP cells are versatile and designed for various applications, including electric vehicles, energy storage systems, electric buses, home energy storage solutions, and applications for UPS. Their thermal stability and safety profile make them suitable for large-scale deployment.

Recharge Power, a subsidiary of J&V Energy Technology, showcased its battery energy storage systems at Energy Taiwan, including projects in Taiwan and Thailand. The battery storage system integrator also has an engineering, procurement, and construction (EPC) business in Taiwan, in addition to offering energy management services (EMS).

It has a track record of 299 MW/617 MWh in project construction in Taiwan, including an alkaline fuel cell installation for state-owned utility Taipower and a solar-plus-storage array. Earlier this year, J&V Group announced plans to work on three of Taiwan's largest energy storage sites, each with a capacity of 100 MW. It has started constructing 200 MW of capacity, with completion expected within two years, to stabilize the Taiwanese grid and integrate more renewables into the island’s network.

Solar recycling

Alex Peng, founder and chairman of RePVTech, said that the company aims to recycle up to 60% of PV module materials using ethylene-vinyl acetate (EVA) technology. It is collaborating with Taiwan's Industrial Technology Research Institute (ITRI) and partners in Japan and Germany to promote a circular economy in solar energy.

RePVTech uses advanced EVA film technology in its recycling process to effectively separate aluminum, glass, silicon, silver, and copper, enabling the intact reuse of glass and silicon. Peng noted a need for better PV module reuse and recycling practices, as current methods often involve crushing waste, leading to significant material loss. By collaborating with Japanese partners, RePVTech aims to generate annual revenue from recycling existing PV waste instead of waiting decades for returns from end-of-life PV projects.

“In the next two years, there will be a waste boom from Japan, from Europe,” said Peng. “So we are working very closely with the US, Japan, India, and Europe to build this global ecosystem.”

Agrivoltaics and aquaculture

New Green Power (NGP) started out with solar projects in Japan and Taiwan a decade ago and has since attracted investments from BlackRock and Google. It operates floating, rooftop, and ground-mounted solar systems in Taiwan and is exploring dual-use options like agrivoltaics and fishery integration.

Despite regulatory challenges and misconceptions among farmers about solar, NGP said it remains dedicated to sustainability and is expanding into electric vehicle charging and battery storage solutions.

“Most promising in the next few years is still going to be the dual-use,” Leo Seewald, chairman of NGP, told pv magazine. “But we're excited about doing agricultural stuff, because there is a lot of land in Taiwan that's not being farmed anymore.”

Despite weather disruptions, the Energy Taiwan & Net-Zero Taiwan 2024 trade show hosted 470 exhibitors, up 25% from the previous year. Tim McBride, Tesla's business development manager, neatly summarized the key concerns of the week by emphasizing how grid resilience features in its Powerwall home battery system like “storm watch” keep homes powered during outages. And Prem Chandan, R&D manager for lithium titanium oxide (LTO) battery maker GUS Technology, underscored the importance of longevity and recycling in sustainable battery production, ensuring batteries can be repurposed for future use.

“Going towards green is like not just manufacturing some batteries,” said Chandan. “It’s much easier to recycle. And these battery components, for example, the LTO, if you recycle, you can use it in many other applications.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.