A group of researchers led by the NingboTech University in China has fabricated an inverted perovskite solar cell with an interface passivator based on lead carbanion (Pb–C–).

Inverted perovskite cells have a device structure known as “p-i-n”, in which hole-selective contact p is at the bottom of intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure but reversed – a “n-i-p” layout. In n-i-p architecture, the solar cell is illuminated through the electron-transport layer (ETL) side; in the p-i-n structure, it is illuminated through the hole‐transport layer (HTL) surface.

Inverted perovskite solar cells are known for their impressive stability but have been held back by lower efficiency in turning sunlight into electricity. This issue mainly arises at the point where the perovskite layer meets the electron transport layer, causing energy loss instead of being converted into useful power. The energy loss is primarily caused by carrier recombination, especially at the interface between perovskite and the electron transport layer.

“Lead carbanion complexes are one of the least explored and understood carbon complex species and, so far, have only been observed in the liquid phase,” The research's lead author, Zhenhua Xu, told pv magazine. “In our work, we present the synthesis of bulk lead carbanion complexes and aims to explore their influence on photoelectric properties of perovskite solar cells.”

In the study “Lead carbanion anchoring for surface passivation to boost efficiency of inverted perovskite solar cells to over 25%,” which was recently published in the Chemical Engineering Journal, the scientists explained that, with the carbanion treatment, the residual lead cation (Pb2+) at the interface could be neutralized and fully coordinated.

“A comprehensive investigation of perovskite films properties, using photoluminescence (PL) mapping and scanning electron microscope (SEM) images, revealed that carbanion passivation reduces defect-rich domains and decreases grain isolation on the perovskite surface,” Xu stated.

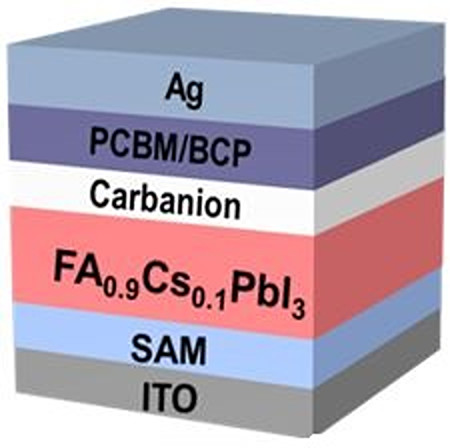

The group built the solar cell with a substrate made of indium tin oxide (ITO), a self–assembled monolayers (SAM) as an HTL, the perovskite absorber, the Pb–C– passivator, an ETL based on phenyl-C61-butyric acid methyl ester (PCBM), a bathocuproine (BCP) buffer layer, and a silver (Ag) metal contact.

Tested under standard illumination conditions, the device efficiency of up to 25.16%, an open-circuit voltage of 1.17 V, a short-circuit current density of 25.30 mA/cm2 and a fill factor of 85.0%. “This strong performance was primarily attributable to a high open-circuit voltage of 1.17 V and a minimal voltage loss of 0.38 V,” Xu further explained, adding that cell achieved the highest open-circuit voltage ever recorded for an inverted perovksite PV device. “The perovskite surface was anchored with strong Pb–C− bond, giving a stable device with lifespan over 3 months.”

Looking forward, the research group is planning to investigate other lead carbanion complexes with different cations, which are expected to synthesize more crystals, and should find applications beyond solar photovoltaics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.