Researchers at the Fraunhofer Institute for Solar Energy Systems (Fraunhofer ISE) in Germany have been working on alternative covers for vehicle-integrated PV (VIPV) modules that are lightweight, with competitive optical properties, while still providing resistance to hailstones and other types of mechanical impact.

Earlier research made it clear that there was a need for alternative polymer-front-sheets that outperform those made of ethylene tetrafluoroethylene (ETFE), according to corresponding author Andre Schüler who was with the Fraunhofer ISE during the research, before joining German PV integrator Next2Sun.

One of those alternatives is glass fiber-reinforced polymer (GFRP) based on epoxy composites. After testing it as a front cover material, instead of glass, the team found that GFRP reduces weight by 44% to 74 % compared to conventional cover glass, depending on the stiffness, or thickness, of the GFRP layer, while withstanding several hail impact tests.

“The achieved high-optical-coupling is outstanding and was also of high interest when first presented at the PVinMotion Conference 2024,” Schüler told pv magazine, referring to a special interest event in Switzerland earlier this year.

The proof-of-concept study showed that GFRP is “definitely an interesting material” as are polymer-based solutions, such as polyethylene terephthalate (PET) or polycarbonate, according to Schüler.

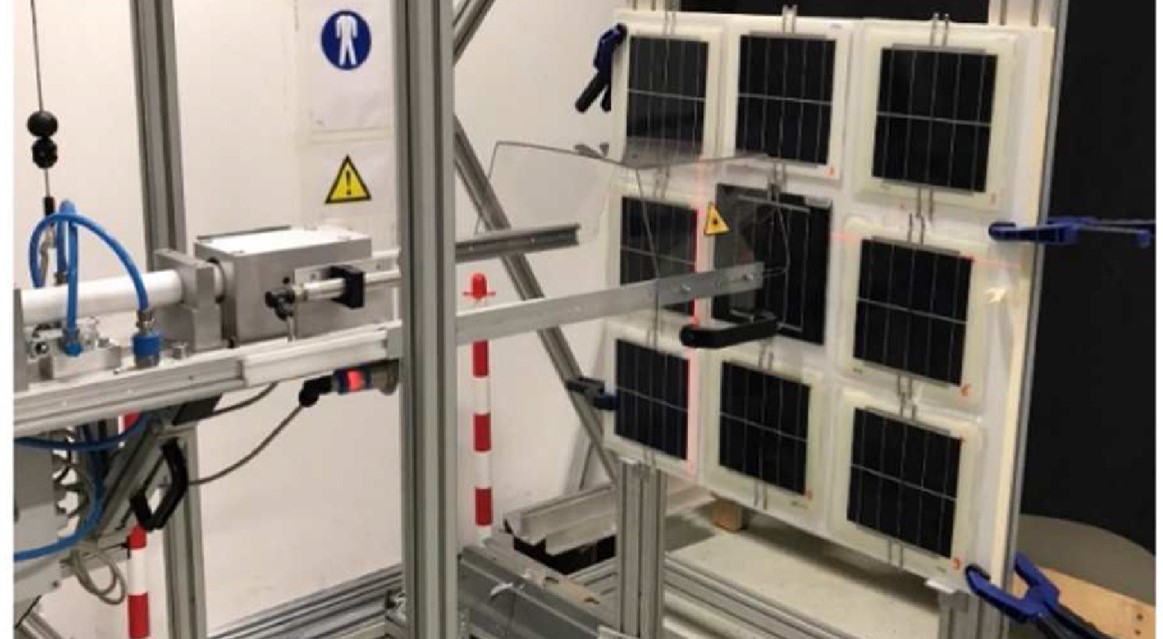

The team tested a variety of front-sheet combinations, including polymer-based modules made with ETFE of 250 μm thickness, two with PET front-sheets with 275 μm and 300 μm thickness, which were reference modules, and the GFRP front-sheet modules with approximately 800 μm thickness.

There were six GFRP front sheet variations with two-, three- and six-layers, and a variety of areal glass fiber weights, GFRP weights and GFRP thicknesses. Three module approaches were investigated, a direct fiber lamination approach, a vacuum-infiltrated glass fiber front-sheet lamination, and a transparent GFRP with lamination industrially produced.

All three variants had rear sides supported by a 1.5 mm GFRP backplate with an added gelcoat layer. Larger modules were used to evaluate the stiffness, while smaller mini-modules were used for the hail test and cut susceptibility tests.

While the modules with GFRP semi-products and modules with industrially produced GFRP front-sheets showed the most promising optical coupling, the modules produced through direct lamination were not considered further due to insufficient optical coupling, according to the researchers.

The pre-infused GFRP front sheet of the PV module stack demonstrated “remarkable optical coupling, maximum power losses of 4%, and low susceptibility to failures during the manufacturing process.”

Modules with GFRP-front layer withstood thermal cycling tests with low power losses depending on the individual GFRP layer, according to the team. The cut susceptibility tests reportedly showed an increased performance compared to modules with a polymeric front layer.

“Provided that the GFRP front-sheets can cost-efficiently be produced on a large scale, the GFRP module manufacturing concept remains very close to the standard lamination process of PV modules by simply replacing the polymer-based front-sheet foil with a GFRP semi-product,” said the team, but it also stressed that further development is necessary for the optimization of the module stack against humidity and UV exposure.

Regarding the potential for tech transfer, Schüler said, “For transfer to industry, the IEC requirements would need to be held in all configurations.” It would mean adjusting the lab process to a GFRP supplier. “So far, this is an interesting proof-of-concept but not an industrial product,” he said.

The work is detailed in “Towards fiber-reinforced front-sheets for lightweight PV modules in VIPV,” published in Solar Energy Materials and Solar Cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.