A research team in China has developed a novel real-time shadow detection method for PV modules. It uses computer vision for the task, with techniques that enhance the information of the live feed to identify the shadow in changing lighting conditions.

“This method has a significant reference value for shadow monitoring of large PV arrays. It provides new technical means for intelligent and accurate operation and maintenance of PV systems,” the researchers said. “We believe this work can potentially monitor the shadow of PV arrays in real-time, and we look forward to further research to extend it to more application scenarios.”

Starting with a live video feed, the novel method analyzes each frame, first by extracting the PV module area. Then, to address the problem of illumination variation, the technique uses gamma transformation, which is a computer vision method based on an algorithm that corrects image brightness without any references.

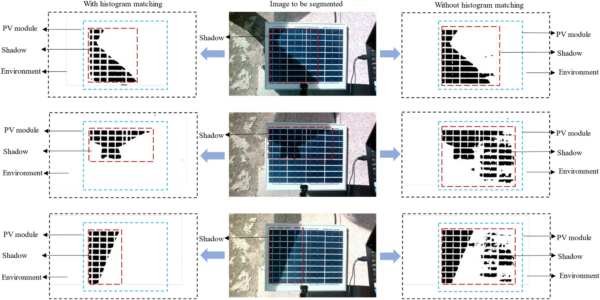

In the next step, the image contrast is enhanced with histogram matching, another computer vision technique that brightens an image by looking at the histogram of a reference image. It then uses gray-level slicing to segment the shaded part of the PV modules, from which the actual shade output is obtained.

Image: Northeast Agricultural University, Scientific Reports, CC BY 4.0

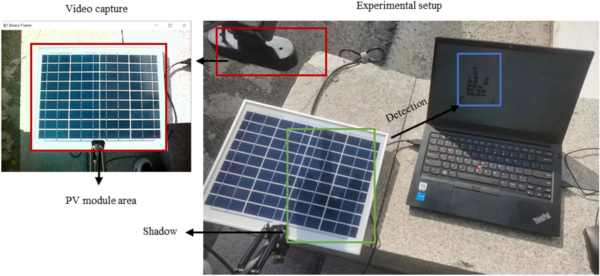

“To simulate the actual working environment better, the validation experiment in this paper was designed as a fixed-position camera, with the environment around the PV module,” the group said. “The image capture device consists of a mechanical bracket, a camera with a frame rate of 30FPS, and an adjusting device. The PV module comprises 36 solar cells of 220 mm x 770 mm, arranged in 4 columns and 9 rows, pasted on the white back sheet, and covered with tempered glass.”

The experimental setup was located in Harbin, China, for the entirety of August 2023 and captured 90 videos of one hour each. In total, 4,815 minutes of video were taken, representing different lighting conditions and occlusion levels. About half of the recorded time was used to analyze and train the model, while the rest was used to test it. It was also compared to four other shadow detection models, namely the Canny edge detection, multilevel thresholding, random forest, and convolutional neural network (CNN).

“The average recognition accuracy (ACC) of this method is verified to be 0.98 by the test set, which is higher than the existing Canny edge detection recognition method,” the results show. “The method's F0.5 and F2 values are 0.87 and 0.85, respectively, which are good in terms of precision and recall. In addition, the average time required by the method to process an image frame is 0.721 s, which has good real-time performance.”

For compression, the Canny method had an ACC of 0.95, F0.5 of 0.76 and F2 of 0.79, and a frame processing time of 0.684 s. Multilevel thresholding performed with an ACC of 0.94, F0.5 of 0.75 and F2 of 0.77, and a frame processing time of 0.934 s, while random forest had an ACC of 0.89, F0.5 of 0.31 and F2 of 0.35 and a frame processing time of 1.067 s. Finally, CNN had an ACC of 0.82, F0.5 of 0.38 and F2 of 0.62, and a frame processing time of 0.603 s.

Their findings were presented in “The real‑time shadow detection of the PV module by computer vision based on histogram matching and gamma transformation method,” published in Scientific Reports. The research team included academics from China's Northeast Agricultural University and Shenzhen University.

Image: Northeast Agricultural University, Scientific Reports, CC BY 4.0

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.