Researchers from Italy’s University of Camerino have developed a novel way to recover silver from end-of-life solar cells.

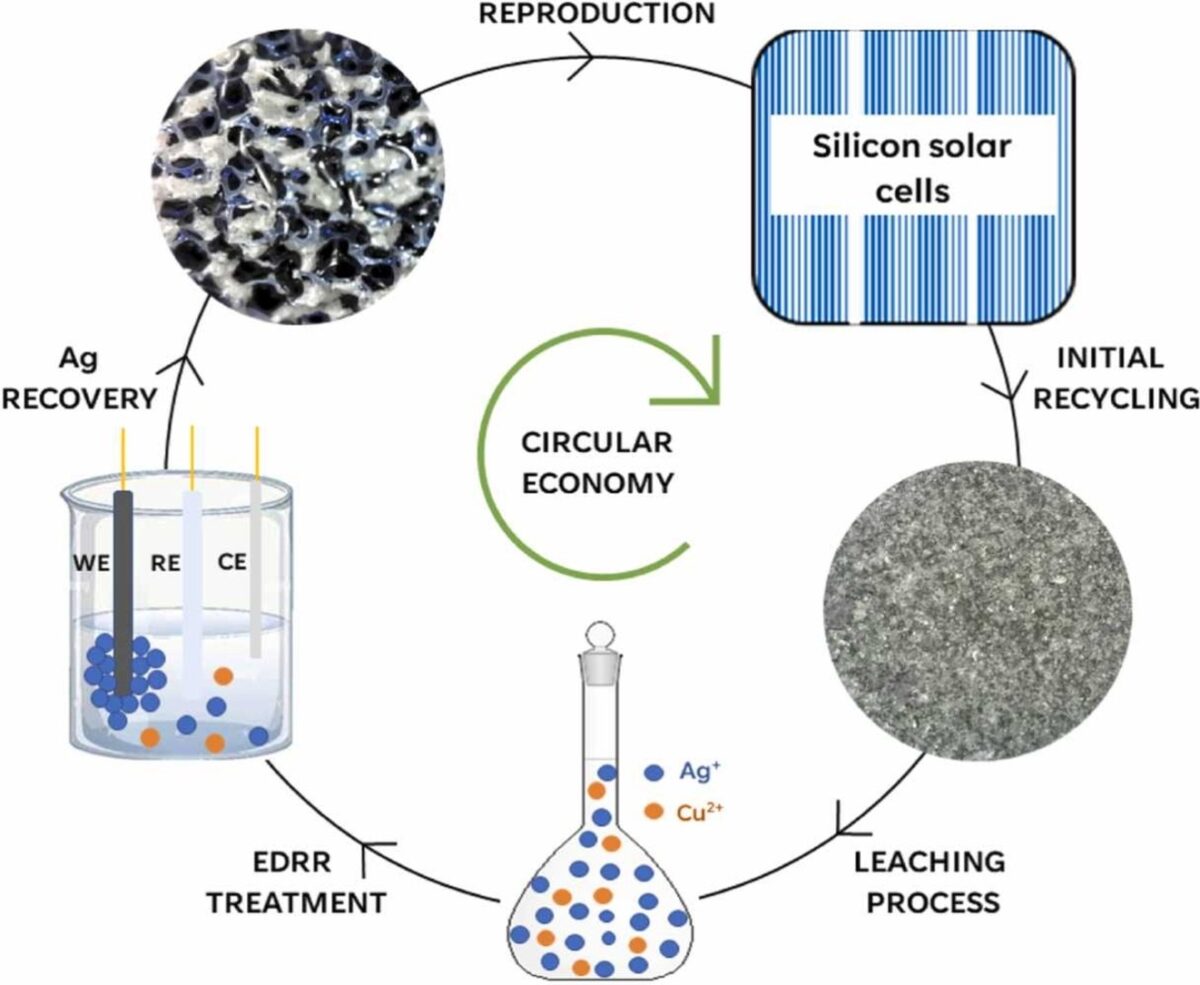

Combining hydrometallurgical and electrochemical processes, they were reportedly able to recover pure silver at an efficiency of 98%. Hydrometallurgical processes, or leaching, use aqueous solutions to extract metals, while electrochemical processes refer to the use of electric currents to drive reactions in metals.

“The retrieval of raw materials is crucial for multiple reasons,” explained the academics. “Conventional metal extraction techniques, such as open-pit mining, can inflict substantial harm on the environment and neighboring ecosystems. Therefore, employing a metal recovery process based on industrial wastes can mitigate the environmental impact associated with metal production. Additionally, metal recovery generally requires less energy than extracting metals from ore, leading to reduced energy consumption and lower carbon emissions, especially if the recovery rate is comparable to or higher than traditional extraction methods.”

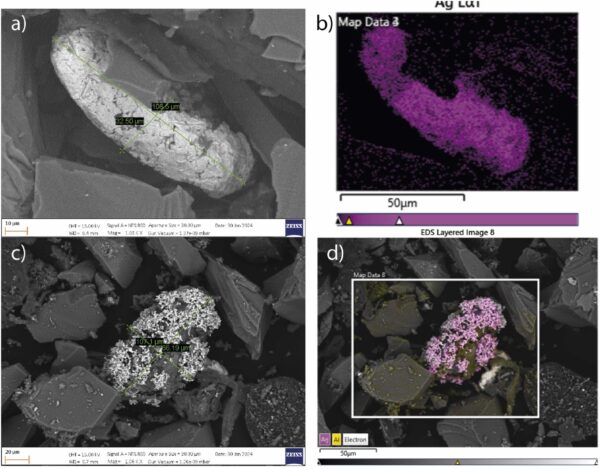

Due to the close values of the standard reduction potential of silver and copper, the leaching of silver particles from PV waste is challenging. To overcome this, the researchers proposed a combined base-activated persulfate and ammonia, with persulfate acting as an oxidizing agent, while the system itself generates a protective hermetic layer of copper (II) oxide, preventing its own leaching.

To test the proposed process, the researchers conducted an experiment consisting of varying parameters for the leaching process. Those were the concentration of ammonia (NH₃) in a solution, measured in moles per liter (mol/L); PV waste sample, in grams per liter (g/L); potassium persulfate (PPS), in mol/L; and reaction time, in minutes. The temperature was kept at 25 C and the stirring rate at 300 rpm during all the experiments.

Image: University of Camerino,

Environmental Technology & Innovation, CC BY 4.0

“The following conditions were chosen as best: 0.5 M of NH₃, 0.2 mol/L of PPS, S/L ratio to 50 g/L, and reaction time set to 60 min,” the academics explained. “Two additional experiments were conducted under these conditions to assess reproducibility. When combined with the two previous tests from the experimental design, an average of 85.0±2.6% was achieved at a 95% confidence interval.”

Despite these good results, 85% of the recovered pure silver was considered insufficient by the research group, which decided to initiate the electrochemical process. Namely, the electrodeposition-redox replacement (EDRR) approach using a pulsed electrodeposition method. “This technique, previously reported in the literature, enables the recovery of highly pure silver metal from hydrometallurgical leachate containing copper ions,” the team explained.

The best conditions for silver recovery were found to be with the EDRR approach, which reportedly achieved an efficiency of 98.7%. “It is noteworthy to mention that this approach proves to be selective in its recovery of silver and does not require any chemical addition. This unique feature renders this methodology competitive in comparison to conventional processes,” the scientists concluded.

The novel method and the results of the experiments were presented in “Silver recovery from silicon solar cells waste by hydrometallurgical and electrochemical technique,” published in Environmental Technology & Innovation. The study was conducted in partnership with ORIM, an Italian company specializing in metal recovery from solid waste.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.