A group of researchers from MIT World Peace University in India has conducted an extensive review of all direct expansion solar heat pump (DX-SHP) technology for domestic heating applications like water heating, solar drying, space heating, and industrial process heating.

“The primary contribution of our work lies in the systematic discussion on innovative design and optimization of the solar collector-evaporator,” the research's corresponding author, Rahul Ashok Patil, told pv magazine. “By integrating the evaporator directly within the solar collector, researchers achieved significant improvements in thermal performance and system efficiency compared to traditional indirect systems. Additionally, our study provides valuable insights into the design parameters and operating conditions for optimizing the performance of direct expansion solar heat pumps.”

According to Patil, the integration of PV power with our system is indeed feasible and can enhance its overall performance. “By utilizing PV-generated electricity to power the compressor and auxiliary components, the system's energy efficiency can be further improved,” he explained. “Moreover, the integration of energy storage systems can help to optimize the utilization of both solar thermal and PV energy.”

DX-SHP systems can reportedly produce hot water from 15 C to 60 C at an average coefficient of performance (COP) of 1.5 to 4.5 and can perform optimally under frosting conditions. “Research shows that for optimum solar heat pump performance, solar radiation ranges from 350 W/m2 to 700 W/m2, wind speed from 0.5 m/s to 2.5 m/s, and ambient temperature from 5 C to 35 C,” the academics emphasized.

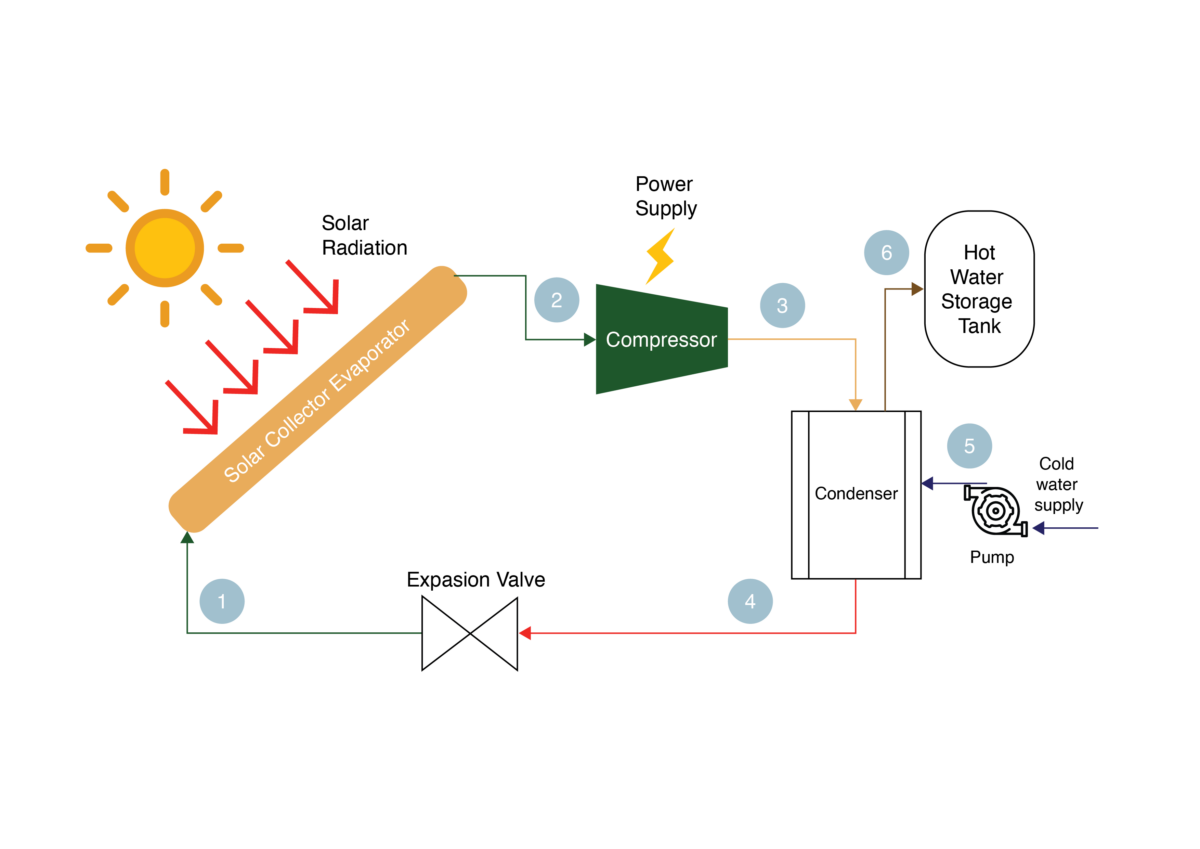

They generally consist of a solar collector-evaporator, a compressor, a condenser, and an expansion valve that operates within a heat pump cycle. The solar collector, which can be based either on a solar thermal unit alone or a photovoltaic-thermal (PVT) panel, is defined by the research group as the crucial component of the system, as it directly expands the refrigerant and collects heat from both solar and ambient air, with the latter prevailing in overcast days.

“The solar collector-evaporator is directly exposed to solar radiation,” it explained. “The refrigerant flowing through the tubes absorbs heat energy from the solar thermal conversion and ambient air. The refrigerant then pumps the heat from the evaporator to the condenser through the compressor.”

In all system configurations, waste heat energy, direct heating, or heated wastewater are used as heat energy inputs to the evaporator, which is crucial for capturing solar thermal energy and transmitting it to the refrigerant.

The researchers highlighted that finned tube collector-evaporators should be the preferred option, as they work well in all weather conditions, with their usage not being affected by temperature or mode of operation. “As temperature and solar radiation increase, COP increases, and heating time decreases,” they added. “Increasing compressor frequency decreases heating time and energy consumption while increasing evaporator heat gain.”

They also recommended adopting environmentally friendly refrigerants such as R290, R600, R1234ze (E), R1270, and R1234yf , as well as using nanofluids to improve thermal and electrical performance in PVT collector-evaporators.

“Future research should explore using heat transfer fluids in roll-bond and air source evaporators as indirect expansion heat exchangers instead of refrigerants,” they concluded. “This includes evaluating performance, optimizing various fluids, and investigating system integration and sustainability for broader implementation.”

Their review was presented in the paper “Recent Advancements in Solar Collector-Evaporator for Direct Expansion Solar Heat Pump,” published in the International Journal of Thermofluids.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Looking at it, it’s nuts everywhere but mountains; the evaporator should have very hot exhaust but not having a riser head means no pressure to run a turbine rather than compressor drawing electricity to run even hotter water heat exchange. That 530°F to water intake T junction… Off to read.