This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Kalpana Systems launches roll-to-roll spatial atomic layer deposition tools

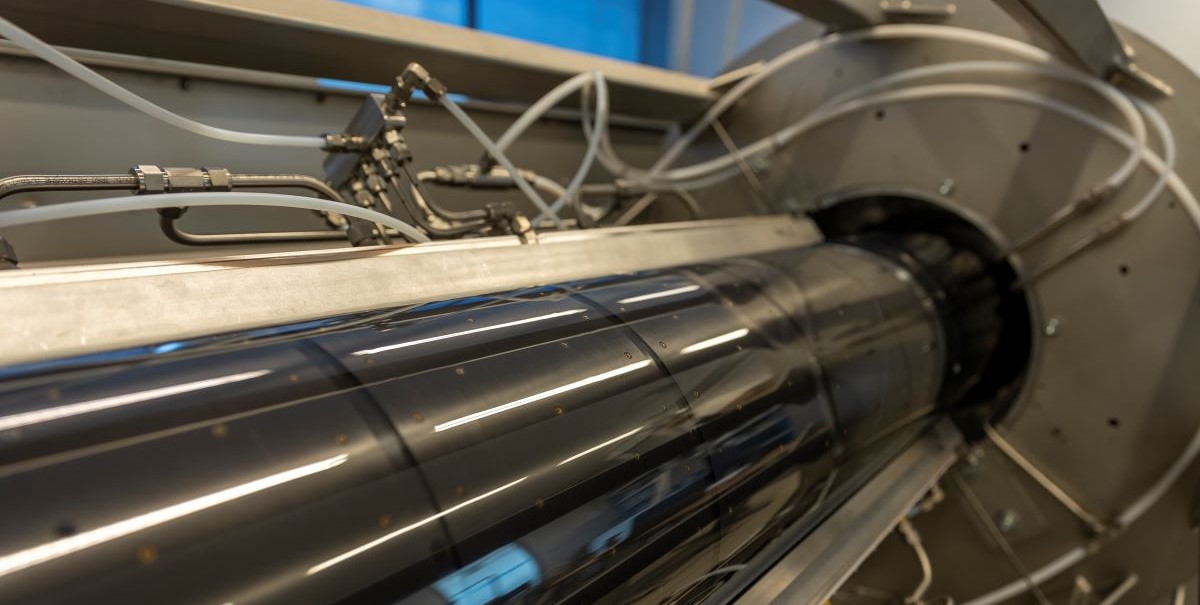

Image: Kalpana Technology

Kalpana Systems, a Dutch thin film equipment company, is launching spatial atomic layer deposition (sALD) equipment to be used in roll-to-roll manufacturing processes in the manufacturing of solar PV, organic light emitting diodes, batteries and packaging.

The startup company recently raised €3.5 million ($3.82 million) in funding from corporate and institutional investors, including a government grant.

“Since the company was founded in 2021 we've been working on developing the first machine, which is operational since December 2023. The newly raised funds will be used to further develop the machine from prototype to a commercial product and scaling of the production,” Diederick Spee, chief executive officer of Kalpana Systems, told pv magazine. “We are working with several customers in the solar cell, packaging and battery markets to test the performance of the sALD layers on their products.”

The spatial atomic layer deposition technology is known for depositing high-quality functional thin layers with atomic precision in a way that does not induce sputter damage. In the PV industry, such sALD barrier layers can be used for the encapsulation of flexible solar cells or as a buffer layer within the cell.

“There is a lot of interest from perovskite and organic solar cell producers who face stability and durability challenges and are looking for cost-effective encapsulation methods,” said Spee. “Our initial focus is on the application of barrier layers, which are relevant for all market segments.”

Kalpana Systems equipment is designed to support the high throughput required for industrial processes with web speeds of up to 10 m/min. It enables the deposition of multiple layers of various precursor materials in one deposition process, and its atmospheric pressure features enable inline integration, and combinations with other deposition techniques.

Kalpana Systems is developing two models called K300 and K600, respectively. Both support process temperatures of 80 C to 150 C. “The first commercial system, the K300, will however most likely be deployed in the solar or flexible electronics industry, where production speed requirements are more in line with the specifications of this machine.” It supports web widths of 100-600 mm and provides a maximum ALD process speed of less than 200 cycles/m2/min.

For battery and packaging applications, the K600 “will be able to operate at higher line speeds and can coat more complex layers” typical in the battery or packaging industry, according to Spee. It supports web widths of 600-1500 mm and a maximum ALD process speed of 200-800 cycles/m2/min.

Both models can handle a variety of substrates, including flexible material. Spee stressed that the equipment is not industry-specific, rather it can be deployed in “any type of roll-to-roll production process” as the operational temperature, line speed, web dimensions, and related parameters are programmable.

A lead time of 9 to 12 months for equipment orders is foreseen, including installation and site acceptance tests at customer sites. Spee added that although the system is “easy to operate” and functions like other types of roll-to-roll processing equipment, Kalpana will offer different levels of support during the onboarding of the customer depending on their needs and requirements.

“The uniqueness of Kalpana’s roll-to-roll technology lies in its high volume, throughput, and rapid production time,” said Frederic Petit, a partner at Emerald Technology Ventures, the advisor to SIG InnoVentures, one of the company’s investors in a statement. “This sets them apart from other providers in the market and allows for wide market adoption including packaging applications.”

The company’s investors include Dutch growth stage investor Fairtree Elevant Ventures, Switzerland-based SIG InnoVentures, the corporate venture arm of SIG, a major producer of food and beverage cartons and packaging, and the Energy Transition Fund Rotterdam.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.