Researchers from India's Shoolini University have conducted a field experiment to analyze the effect of thermoelectric coolers (TECs) and water cooling on the temperatures of PV modules.

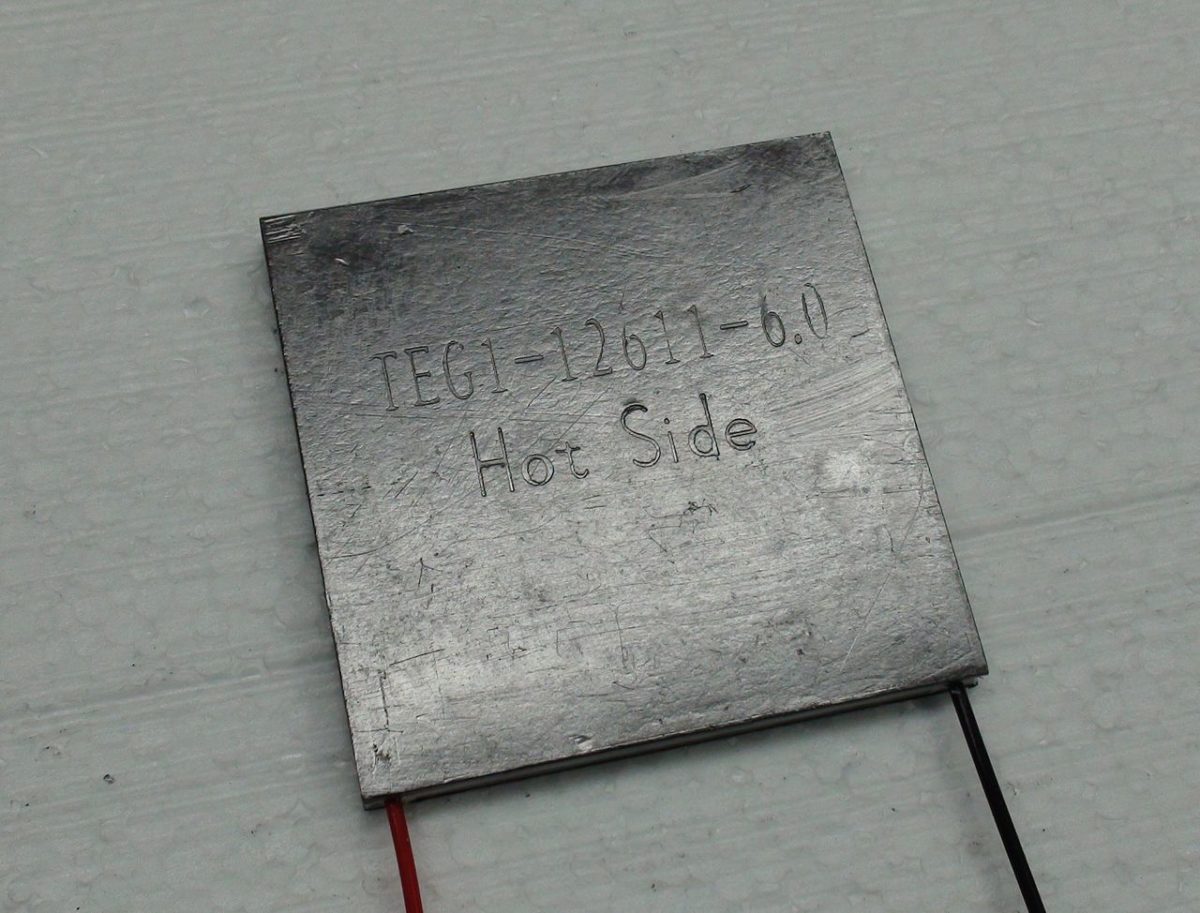

“Thermoelectric devices are solid-state devices that operate on the principle of the Seebeck effect for power generation and on the Peltier effect for cooling operation,” explained the researchers. “Devices optimized for power generation are known as thermoelectric generators (TEGs) and for cooling are known as thermoelectric coolers (TECs).”

The Seebeck effect occurs when a temperature difference between two different semiconductors produces a voltage between the two substances. TECs are commonly used for industrial applications to convert excess heat into electricity. However, their high costs and limited performance have thus far limited their adoption on a broader scale.

The experiment was conducted on a sunny August day between 11:15 and 13:35 in Shimla, the capital of the northern Indian state of Himachal Pradesh. Two polycrystalline silicon PV cells — one with water cooling and TEC (PV cell 2) and one without cooling (PV cell 1) — were used for the research. Both cells measured 60 mm × 60 mm x 3 mm.

Cell temperatures were measured across nine times blocks via two Pt100 RTD temperature sensors fixed at the back of the devices. In some cases, the cells were shaded, and in some not. In other cases, TEC was switched on or off, and in other cases, the water cooling was either active or not.

“The experiment clearly demonstrates that thermoelectric module (TEM) cooling is very effective and is able to maintain PV cell 2 at 25 C while PV cell 1 is operating at a maximum range of 55–63 C, leading to a temperature difference of 30–38 C,” the scientist explained. “The experiment also demonstrates that TEM itself is contributing to at least 10 C temperature difference in addition to water cooling.”

After acquiring those results, the scientists used the PVSyst software to simulate energy loss due to elevated temperatures in 31 cities across Asia, Australia, Africa, and North America. “Results show that average array temperatures for the cities were in the range of 27–57 C, leading to energy loss due to elevated temperature in the range of 6–27%. This highlights the importance of further research and development of PV-TECs for energy enhancement of commercial PV power plants,” they said.

In a different section of the research, the academics took the measured results from cell 1, and compared them to the results of several temperature prediction models. Namely, they have compared it to the nominal operating cell temperature model (NOCT); the National Energy Renewable Laboratory (NREL) USA adjusted NOCT model; Faiman's model; the Ross coefficient model; the Skoplaki model; and the Sandia Lab model.

“A comparison of six PV cell temperature prediction models with actual values infers that standard NOCT and Faiman models are accurate when wind speed effects are not significant,” the academics emphasized. “However, for conditions where wind speed is a dominant parameter, other models are likely to give more accurate results. These results are important for future modeling of integrated PV-TECS systems for performance prediction in actual outdoor conditions.”

Their findings were presented in the study “Modelling and experimental investigation of cooling of field-operating PV panels using thermoelectric devices for enhanced power generation by industrial solar plants,” published on Next Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.