What is the “Full-Screen” technology for solar modules?

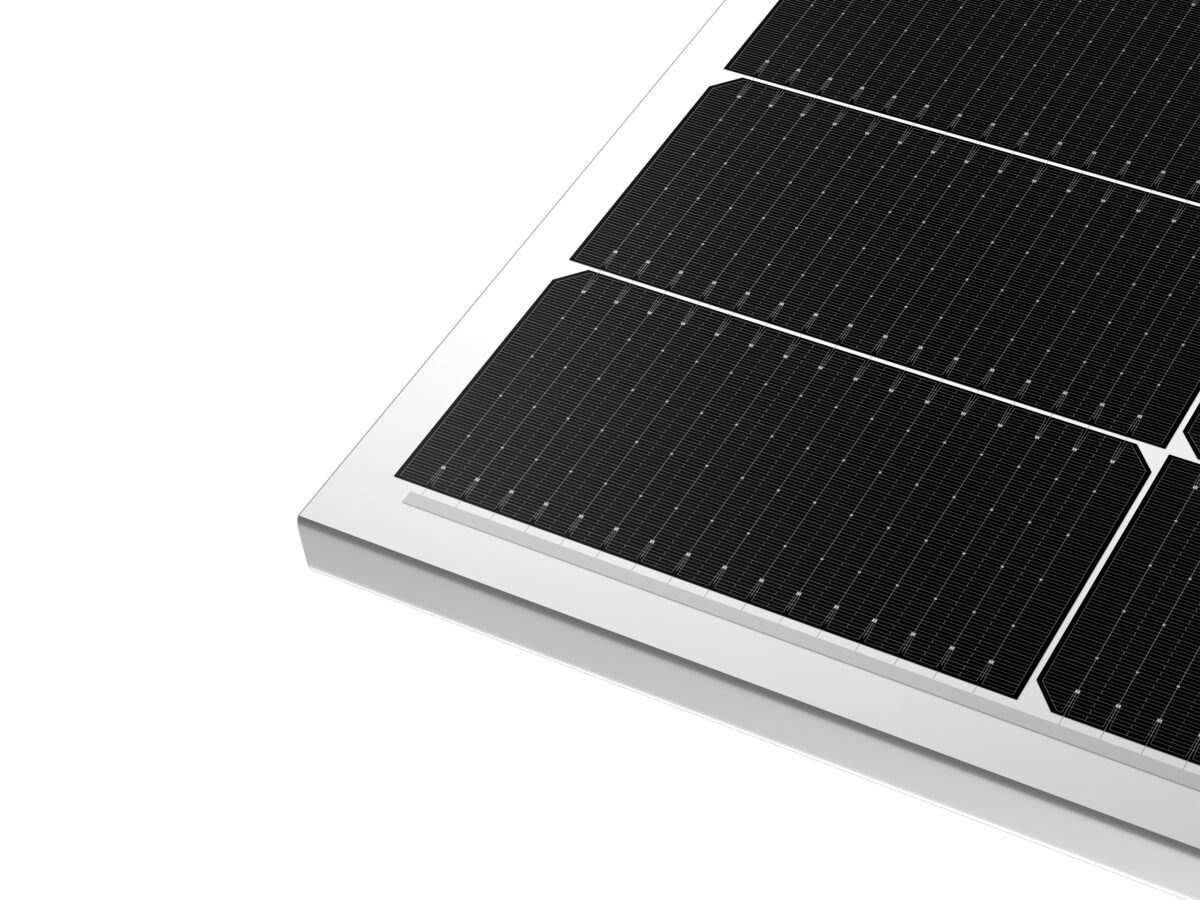

Dr. Jiang Chengyin: Regular solar modules have frames that protrude above the glass surface, causing dust to accumulate since rainwater can't flow off quickly. Through our patented design, we ensure the frame is flush with the surface, allowing rainwater to smoothly run off and carry away dust, achieving a self-cleaning effect. Based on outdoor performance tests, at an installation angle of around 5 degrees, which simulates the typical installation angle on most domestic color steel tile roofs, our Full-Screen modules can achieve an annual energy gain of approximately 11%.

With the elimination of traditional aluminum frame wrapping, can the Full-Screen's flat edge design meet structural rigidity requirements? How does it withstand long-term outdoor sealing performance?

Dr. Jiang Chengyin: Originally, double-glass modules had no frames. With encapsulation of double-sided strengthened glass fully meeting the module's strength requirements. Adding frame designs primarily protected glass edges from damage. Since the distance from the internal cell's conductive part to the module edge is generally over 15 mm, the waterproof sealing insulation width at the edge is also 15 mm, ensuring long-term outdoor sealing. DAH Solar's design eliminates the front frame but retains side and back frames, bonded with high-strength silicone rubber, maintaining glass edge protection. Silicone rubber offers proven durability and weather resistance.

What improvements does DAH Solar's Full-Screen product at this SNEC exhibit offer compared to previous models?

Dr. Jiang Chengyin: Our Full-Screen product has advanced to version 3.0, which is a significant improvement over versions 1.0 and 2.0. First, we have adopted the Full-Screen plus “Dense Busbar” (DBB), which is a design similar to 0BB. DBB technology has several advantages, notably significantly reducing silver consumption during cell production, lowering product costs. Additionally, in module production, we've abandoned high-temperature welding processes, using low-temperature film to bond ribbons to cell surfaces. This low-temperature encapsulation process enhances module power, reduces virtual welding and the likelihood of fractures, improves yield, and extends product life by avoiding flux residues that corrode grid lines. Overall, version 3.0 products show significant improvements in reliability and power generation compared to past versions.

Furthermore, we now use industry-leading rectangular silicon wafers based on 182 mm as the substrate for TOPCon cells. We also employ laser-assisted sintering technology to significantly enhance the product's resistance to moisture corrosion, achieving stable 23.3% cell efficiency in mass production. Additionally, we utilize stacking welding production processes, supplemented by film processing, optimizing mechanical load capacity and other performance metrics. Moreover, responding to customer demands, we've customized the colors of modules to be suitable for rooftops, walls, and sunrooms, and we've received commendation for their aesthetic appeal.

Image: DAH Solar

Can you describe DAH Solar's market distribution and production capacity?

Dr. Jiang Chengyin: Currently, we've shipped approximately 10 GW of modules to over ten thousand distributed projects globally. About half of these projects are installed in China, with the rest distributed across dozens of countries and regions worldwide. Our business was initially domestic in focus, but post-2018, overseas markets rapidly developed, nearing or even surpassing domestic shipments. During a period after the pandemic outbreak, nearly 90% of our company's revenue came from overseas markets. However, in recent years, our focus has shifted back to China, and our domestic and overseas markets are now evenly matched. We have a current production capacity of 6 GW each for both cells and modules, all within China.

Given the current market situation, does DAH Solar have plans to expand production capacity overseas?

Dr. Jiang Chengyin: We've continually evaluated the possibility and suitable locations for overseas factory construction, but due to certain instability factors, there are no confirmed plans yet. Due to concerns about overcapacity and homogenized competition, DAH Solar has been very conservative in expanding production capacity, ensuring it remains within appropriate limits. We prefer leveraging differentiated products to lead in some market segments.

Which overseas markets are DAH Solar's key focus markets currently?

Dr. Jiang Chengyin: Currently, Europe accounts for about 30% of our overseas shipments, with other regions such as Australia, Japan, Southeast Asia, and the Middle East being our key focus markets. Particularly, countries like Pakistan and Saudi Arabia have seen rapid development in recent years and are poised to become the next growth hotspots.

The questions and responses in this sponsored interview article were provided by DAH Solar.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.