A group of researchers led by the Tor Vergata University of Rome in Italy has developed a novel perovskite solar cell and module encapsulation process that purportedly increases device stability without the need for advanced perovskite chemistries with high internal stability or specific edge sealants.

The team said their novel encapsula reduces the thermomechanical stresses at the interface of the encapsulant and rear electrode. It is based on a highly viscoelastic liquid adhesive polyisobutylene (PIB) material and is described as an industrially compatible solution that doesn't require solvents in a strain-free lamination process.

“In this work, differently from commercially available PIB-based encapsulants commonly used in literature for perovskite solar cells, we propose low-molecular weight homopolymer PIB as a transparent, viscoelastic, semi-solid liquid processable in form of laminable films,” the scientists specified. “In addition, we show that the adhesion, barrier and thermal management properties of our homopolymer PIB encapsulant can be improved by the addition of two-dimensional (2D) inorganic fillers, namely few-layer hexagonal boron nitride (h-BN) (nano)flakes produced at industrial scale through a patented wet-jet milling (WJM) exfoliation process of the native bulk powder.”

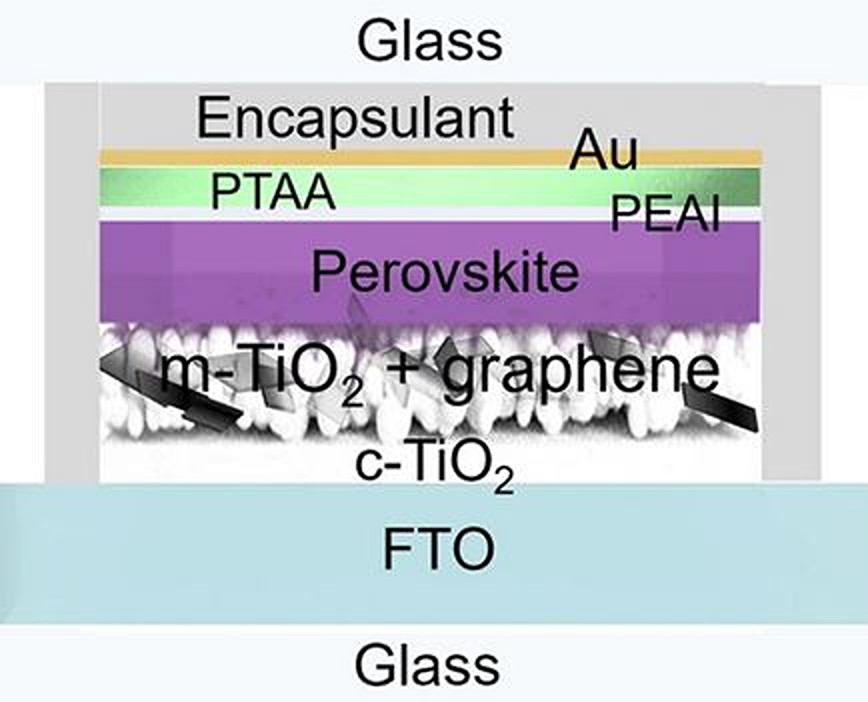

The academics tested their solution on solar cells fabricated on glass substrates featuring both mesoscopic and planar n-i-p configurations, plus a cell with an inverted p-i-n configuration. A semi-transparent bifacial specimen was also tested. The researchers also made modules based on mesoscopic n-i-p cells made with an absorber relying on methylammonium (MA) perovskite material.

They tested two versions of the novel encapsulant. One with two-dimensional fillers made of a boron nitride material (PIB:h-BN) and one without. The cells measured 1 cm2, while the modules had an active area of 10 cm2, based on 5 cells with an active area of 2 cm2.

The devices were encapsulated at 90 C in a differential pressure lamination process based on an automatic two-chamber solar panel laminator supplied by Italian specialist Rise Technology, along with a cooling system. The cells and modules were subjected to multiple accelerated ageing tests, as well as a customized thermal shock test and a modified humidity freeze test.

“The addition of thermally conductive two-dimensional hexagonal boron nitride into the polymeric matrix improves the barrier and thermal management properties of the encapsulant,” said the researchers. “Without any edge sealant, encapsulated devices withstood multifaceted accelerated ageing tests, retaining over 80% of their initial efficiency.”

The group sees the work as a step towards long-term stable modules made with low-temperature and cost-effective encapsulants that can be applied in a high throughput manufacturing line, enabling perovskite solar cells to be competitive with conventional crystalline silicon solar technologies. It also foresees compatibility with a wide range of perovskite compositions.

“Overall, our results indicate that semi-solid/liquid encapsulation concepts efficiently mitigate either thermal and thermomechanical stresses during encapsulant application, while providing excellent barrier performance for the realization of long-term stable PSCs and PSMs, aiming at tackling the competition with Si-based PVs,” concluded the team.

The work is detailed in the paper “Low-temperature strain-free encapsulation for perovskite solar cells and modules passing multifaceted accelerated ageing tests,” published in nature communications. The research team comprised scientists from the Università di Genova, Institute of Structure of Matter (ISMCNR), the Italian National Research Council (CNR), and Istituto Italiano di Tecnologia.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.