Researchers at International Solar Energy Research Center Konstanz (ISC Konstanz) in Germany have developed a new method to measure the contact resistance of solar cell interconnections made with electrically conductive adhesives (ECAs).

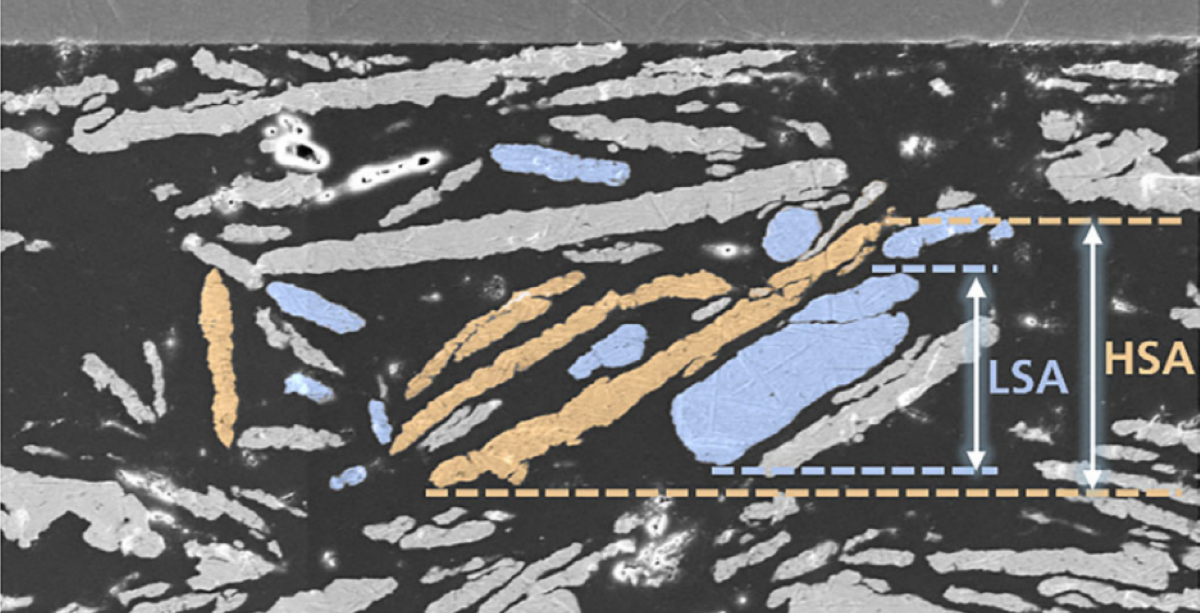

ECAs are made of adhesive polymers with embedded metallic filler particles, such as silver. They can be used in solar PV designs based on ribbon, shingle, and conductive backsheet interconnections. They can also be used in the manufacturing of silicon heterojunction (SHJ) and tandem perovskite-silicon cells.

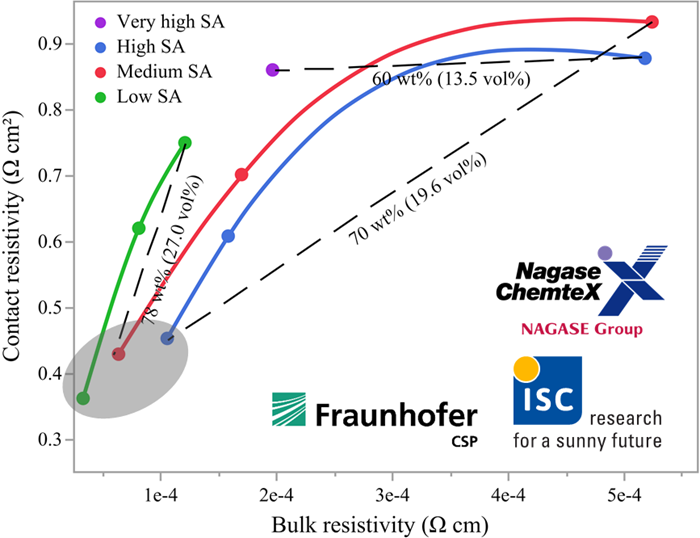

The proposed approach reportedly enables the precise characterization of both contact resistivity and bulk resistivity. “Better ECA bonding measurements enable the optimization of ECA material formulations, using more or less filler, for example, or using different filler shapes, or depositing different geometries of the ECA material on the bonding surfaces,” Daniel Tune, group leader tandems and new materials at ISC Konstanz, told pv magazine. Such ECA modifications are relevant to efforts to reduce manufacturing costs without negatively affecting performance.

The scientists explained that two electrical measurements important to optimizing the use of ECA are contact resistivity and bulk resistivity. Bulk resistivity can be easily measured, but contact resistivity measurements have been more difficult because the calculated resistivity values can be strongly dependent on samples and preparation conditions, making it difficult to compare prototypes in other labs or by other teams.

“Now both resistance measurements across a wide range of samples can be captured using the ISC method, which combines both a dedicated measurement unit and sample design with new algorithms to extract the correct resistivity values from datasets consisting of hundreds of individual measurements,” explained Tune.

When asked about transferring the ECA characterization technology, Tune said that measurements are currently offered as a service to industry and the team is working on finding partners for commercialization.

A demonstration of the characterization technology is described in the study “The effects of increasing filler loading on the contact resistivity of interconnects based on silver–epoxied conductive adhesives and silver metallization pastes,” published by Progress in Photovoltaics.

Popular content

The research showed how optimizing for both bulk and contact resistivity parameters enabled a “significant” reduction in silver, while maintaining a “similar” level of product performance. The paper was a result of a collaboration of researchers from ISC Konstanz, Anhalt University of Applied Sciences, and the Fraunhofer Center for Silicon-Photovoltaics (CSP).

“We aimed to develop a method for reproducible and dependable measurement of the contact resistance of ECA metal interfaces and were sure that with the right measurement setup and statistical treatment it should be possible,” said the study’s lead researcher Maria Ignacia Devoto Acevedo in a press release.

“This is a great example of how a new technique to measure the fundamental properties of a material system can reveal commercially important vectors in material R&D that were previously unknown or only known on a qualitative basis,” stated Tune.

Image: ISC Konstanz

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.