From pv magazine Germany

Three Fraunhofer institutes in Germany have developed “an exciting alternative” to hydrogen production using electrolyzers in the Neo-PEC joint research project. “PEC” stands for “photoelectrochemical cell,” which is a cell that enables direct solar water splitting.

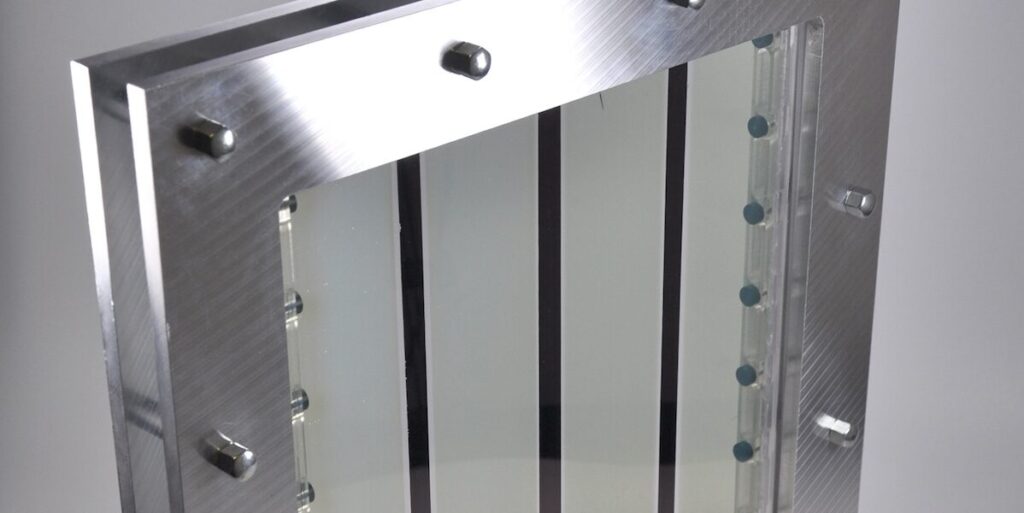

The solution from the research project, presented in June, consists of a module with an area of around half a square meter that can be connected to form larger units and enable “highly flexible hydrogen production using solar energy.”

The “tandem PEC module” consists of two panes of float glass coated with semiconducting materials. One side absorbs short-wave light, while long-wave light penetrates the upper glass layer and is absorbed on the reverse side. The module releases hydrogen on the reverse (cathode) side and oxygen on the upper (anode) side, with the two elements separated.

Over the three-year project, researchers developed high-purity semiconductor materials applied using “particularly gentle coating processes,” increasing hydrogen yield.

Ultra-thin layers measuring nanometers are built on the glass via gas phase, said Arno Görne, group leader for functional materials at Fraunhofer Institute for Ceramic Technologies and Systems IKTS.

“The structures created have a major influence on reactor activity, in addition to the actual material properties, which we have also optimized,” he said. The system is supplied with additional voltage via “photovoltaic elements” in the module, acting “like a turbo that accelerates activity and increases efficiency.”

The result is a reactor that generates hydrogen separately from oxygen, which can be collected directly. Under European radiation conditions, a good 30 kg of hydrogen can be generated with 100 square meters of module area. This allows a hydrogen car to travel 15,000 to 20,000 km. In comparison, solar modules in Central Europe could generate around 16,000 kWh of electrical energy, enough to electrolyze around 300 kg of hydrogen.

According to Görne, the dimensions of the individual units are “limited by the fact that our module splits the water directly, but this also requires electricity to pass from one side to the other. As the module area increases, the increasing resistance affects the system.” The current format is optimal at this stage of development, being “stable, robust, and significantly larger than all comparable solutions.” A key advantage is the scalability of connecting several modules.

The other two institutes involved – the Fraunhofer Institute for Surface Engineering and Thin Films IST and the Fraunhofer Center for Silicon Photovoltaics CSP – have conducted several field tests. They aim to continue their cooperation in a follow-up project and plan to involve companies.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

There is no mention on the amount of time for the generation of the 30 kg using a 100 M2 solar array.