Scientists from South Korea’s Korea Institute of Industrial Technology have developed a deep-learning surrogate model for optimizing module aluminum (Al) frames used in glass-glass bifacial photovoltaic panels.

The scientists said that due to the increasing size and weight of PV modules, Al frames suffer from a higher risk of deflection, which is the degree to which a part of a long structural element is deformed laterally under a load.

“If the module undergoes deformation due to the load, it may lead to cracking or delamination of ribbons inside the module, resulting in an increase in dead cells,” explained the group. “Bifacial modules are relatively heavier compared to monofacial modules. Therefore, when subject to increased surface area, there is a higher likelihood of frame deformation due to self-weight, leading to potential module deflection.”

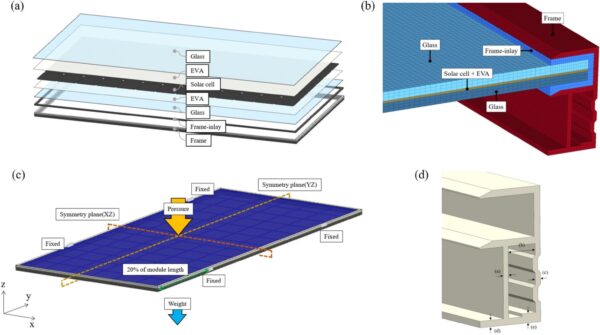

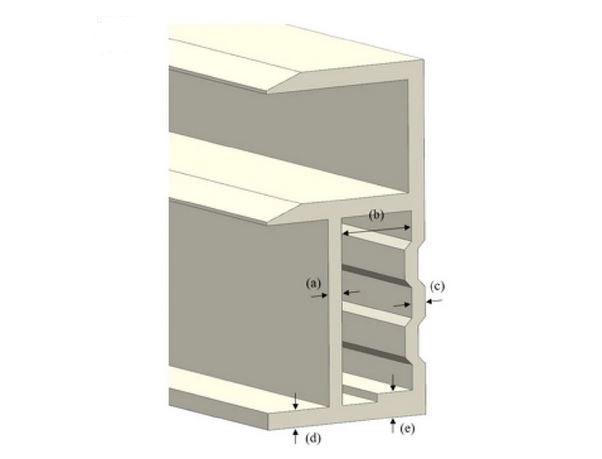

To design their optimization model, the academics first identified five design factors for the frame, including ridges, grooves, and a hollow section. Setting three levels in millimeters for each factor, the group conducted 243 experiments that could identify deflection via finite element analysis (FEA). FEA is a numerical method used to solve problems in engineering and mathematical physics.

However, as FEA demands significant computational resources, the group has created the surrogate module. “Deep neural network (DNN)-based surrogate modeling involves finding an approximate function that minimizes the loss function for the given data,” they explained. “We applied Bayesian optimization, deriving hyperparameters that minimize the loss function.”

Bayesian optimization is a sequential design strategy for global optimization of black-box functions that does not assume any functional forms. It is particularly effective for scenarios where sampling is expensive, and the objective function is unknown but can be sampled.

Image: Korea Institute of Industrial Technology, Scientific Reports, CC BY 4.0

Using the results of the 243 experiments and artificially increasing them, the group then trained and tested the novel model with a ratio of 9:1 respectively. When compared to the real FEA, the FE surrogate model demonstrated high accuracy with the mean absolute percentage error (MAPE) and coefficient of determination (R2) values for deflection and weight being an average of 0.0017, 0.9972 for the training set, and 0.0020, 0.9962 for the test set, respectively.

Following those positive results, the academics moved to optimize the frame of a large-sized 585 W bifacial PV module with 78 M10 cells. It had a commercially available AL frame weighing 3.2 kg. This frame caused a deflection of about 12.3 mm with a displacement of up to approximately 2.8 mm in the opposite direction.

The optimization aim of the novel model is to design a frame that minimizes deflection with the lowest possible weight, which means making a frame thicker can relatively reduce deflection but also increase the production cost. “The factor values that minimize both deflection and weight were found to be a = 1.5176 mm, b = 13.7105 mm, c = 1.5012 mm, d = 2.9898mm, e = 4.3123. At this point, the deflection was 11.1 mm, and the weight was 3.6 kg,” said the scientists.

Image: Korea Institute of Industrial Technology, Scientific Reports, CC BY 4.0

Those results were achieved after the novel optimization model looked into one million datasets. “Generating the 1 million datasets took 0.957 seconds (s), obtaining the predicted deflection and weight values for these datasets took approximately 72.014 s, and finding the optimal values from these predictions took about 0.264 s. In contrast, using traditional FEA to obtain deflection and weight for a single case took about 4,800 s,” they stated.

Using their novel method, they were reportedly able to decrease deflection by almost 9.6% while increasing the frame’s weight by about 12.8%.

Their findings were presented in the study “Design optimization of large‑scale bifacial photovoltaic module frame using deep learning surrogate model,” published in Scientific Reports.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.