A group of researchers led by the Chinese Academy of Sciences (CAS) has fabricated a kesterite (CZTSSe) solar cell that achieved a maximum power conversion efficiency of 14.6% and a certified efficiency of 14.2%.

“The performance of kesterite solar cells is mainly limited by the defect-induced charge loss,” the research's corresponding author, Qingbo Meng, told pv magazine. “We believe through a more comprehensive understanding of the defect formation mechanism in this material system and a more effective control of the defect formation process, we can achieve more advancements in the future.”

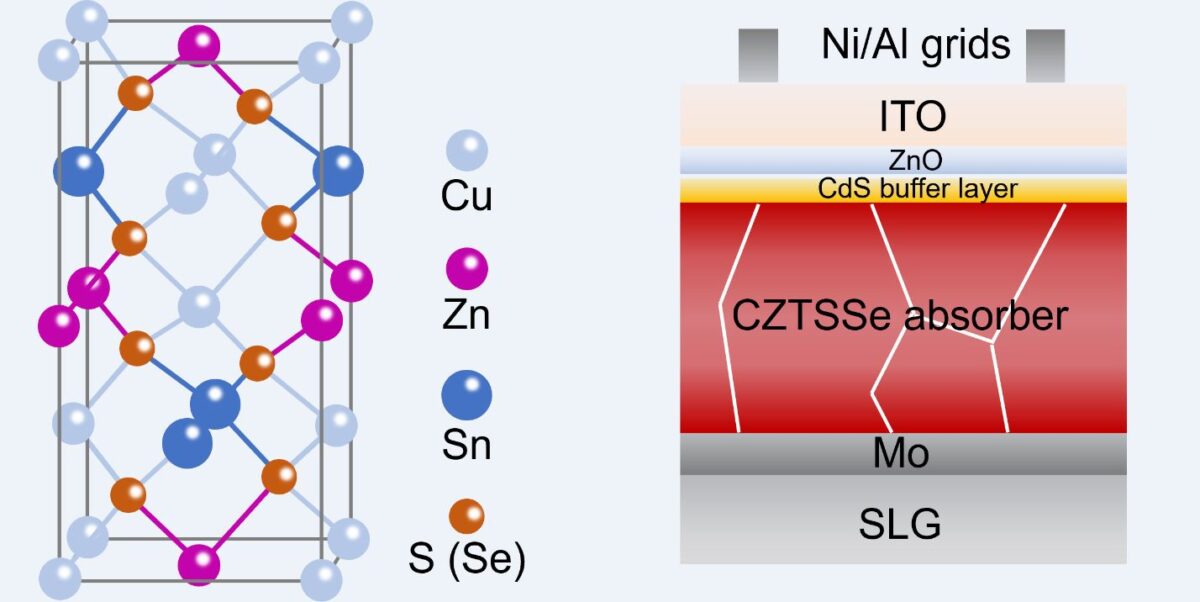

Kesterite is one of the most promising light absorber material candidates for potential use in lower-cost thin-film solar cells. Kesterites include common elements such as copper, tin, zinc, and selenium. Unlike CIGS compounds, there are no supply bottlenecks expected in the future. However, kesterite is still less efficient than CIGS in mass production. The world record for such cells is 12.6%, achieved for large-area devices by Japanese thin-film producer Solar Frontier in 2013.

The Chinese research team utilized what it described as a kinetics-based approach to suppress the formation of deep defects in the CZTSSe absorber. It consisted of using multi-elemental alloying to eliminate tin (Sn) and zinc (Zn) defects in the final CZTSSe material by adding silver (Ag) and cadmium (Cd) via the precursor solution and germanium (Ge) from the back interface. “Elemental alloying has facilitated the exchange of Zn/Sn and Zn/Cu, leading to an accelerated formation of ordered kesterite phase,” the scientists said.

They built the solar cell with a substrate made of soda lime glass (SLG) coated with molybdenum (Mo), the CZTSSe absorber, a cadmium sulfide (CdS) buffer layer, a window layer of zinc oxide (ZnO), and indium tin oxide (ITO) layer, and an anti-reflective coating based on magnesium fluoride (MgF2).

Tested under standard illumination conditions, the device achieved a power conversion efficiency of 14.6%, an open-circuit voltage of 0.55 V, a short-circuit current of 36.6 mA cm−2, and a fill factor of 72.4%. China's National PV Industry Measurement and Testing Center certified that the cell achieved an efficiency of 14.2%.

“The main discrepancy between the certified and our lab result, that is, the fill factor, is attributed to the influence of the MgF2 antireflection layer on the electrical probe contacting,” the academics explained. “These results indicate that multinary alloying can more effectively regulate the reaction kinetics to suppress deep defects in CZTSSe and thus creates more favorable moderate reaction conditions to meet the requirements of large-scale and low-cost industrial manufacturing.”

The new solar cell concept was introduced in the paper “Multinary alloying for facilitated cation exchange and suppressed defect formation in kesterite solar cells with above 14% certified efficiency,” which was recently published in nature energy. “These understandings and the data-driven analysis method presented here also bring more avenues to identify and regulate defects in photovoltaic materials,” the research team concluded.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.