From pv magazine USA

Swift Solar announced the close of its $27 million Series A financing round, which follows on the heels of a $7 million award from the Department of Energy under the Advancing U.S. Thin-Film Solar Photovoltaics funding program.

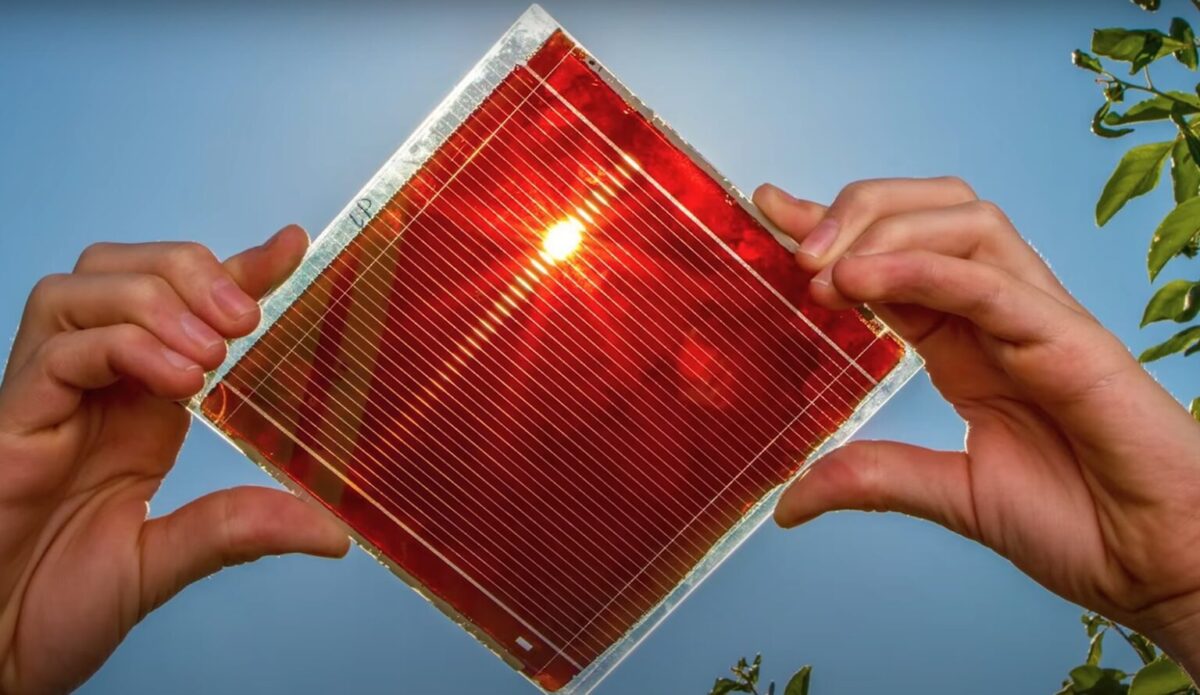

The company, founded in 2017 is a spinout of MIT, Stanford University and the National Renewable Energy Laboratory (NREL), and specializes in perovskite tandem photovoltaics. The new technology combines metal halide perovskites with silicon or other perovskites to make tandem cells that have higher efficiency than traditional solar cells.

The $27 million funding round was co-led by Eni Next and Fontinalis Partners. Also joining the round are new and existing investors including Stanford University, Good Growth Capital, BlueScopeX, HL Ventures, Toba Capital, Sid Sijbrandij, James Fickel, Adam Winkel, Fred Ehrsam, Jonathan Lin, and Climate Capital.

The $7 million DOE funding is part of a $71 million investment, including $16 million from the Bipartisan Infrastructure Law, which supports research, development and demonstration projects in order to help grow the domestic solar supply chain. Swift Solar was one of four awardees that are working on tandem PV devices that pair established PV technologies like silicon and copper indium gallium diselenide (CIGS) with perovskites.

In total, Swift Solar has raised $44 million to scale its technology as it prepares to break ground on its first manufacturing facility.

“Solar is the future of energy—not just clean energy,” said Joel Jean, co-founder and CEO of Swift Solar. “Our advanced perovskite solar cells can outperform anything currently available on the market.”

The company’s novel vapor deposition technology may help it to accelerate the manufacture of its tandem solution. The new method is a non-batch process that solves two problems associated with the use of established vapor processing in perovskite material manufacturing – the slow speed of deposition and the non-continuous nature of batch processing.

“Our deposition approach allows for the continuous deposition of a fully absorbing perovskite material within less than five minutes,” corresponding author Tobias Abzieher from Swift Solar, a U.S.-based perovskite PV startup, told pv magazine. “Solar cells prepared with these materials also outperform previously realized efficiencies of vapor processed inorganic perovskite solar cells significantly.”

In its announcement, Swift Solar noted that perovskite solar cell production uses less material and less energy, which should drive down manufacturing costs and carbon pollution, potentially decreasing the cost of solar by up to 30%. “The perovskite supply chain could be based entirely in the United States and aligned countries, creating a major opportunity to expand domestic manufacturing,” according to Swift.

Swift Solar’s initial products will be designed for integration in high-performance solar-powered products such as on car rooftops or space-based satellites. The company reports that it is planning a rooftop solar product for release in the future.

Swift Solar was recently named one of TIME’s Top GreenTech Companies in America. In April, The Solar Energy Manufacturers for America (SEMA) Coalition announced that Swift Solar was a new member.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Perovskite based PV solar cells and modules have suffered from fast degradation rates and lack of long term stability. Have those issues being resolved as to warrant the investment? Or will this be a a-Si version 2.0 story?