Austrian researchers assessed the degradation potential of thermoplastic polyolefin (TPO) encapsulants for use in glass-glass modules, as an alternative to conventional ethylene vinyl acetate (EVA) copolymer and polyolefin elastomers (POE).

“TPO films are currently used for niche products, such as colored double glass modules and building integrated PV-modules. Double glass modules require encapsulants with a significantly lower amount of reactive by-product. In contrast to crosslinking EVA and POE encapsulants, TPO materials allow for ease of processing and recycling,” Martin Tiefenthaler, a researcher at Johannes Kepler University Linz (JKU), told pv magazine, adding that TPO films are free of peroxides and do not contain vinyl acetate comonomer units, which are prone to hydrolytic degradation.

In the study, the team prepared double glass laminates, measuring 25 mm × 25 mm × 7 mm, using three TPO film adhesives, each with a different formulation, TPO-3.5, TPO-UV, TPO-F, and supplied by Austria's Borealis. Two additional specimens made with EVA and POE were used as benchmarks.

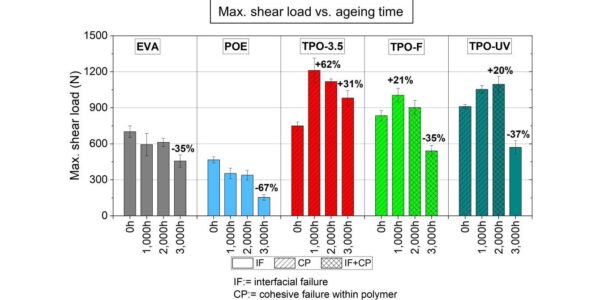

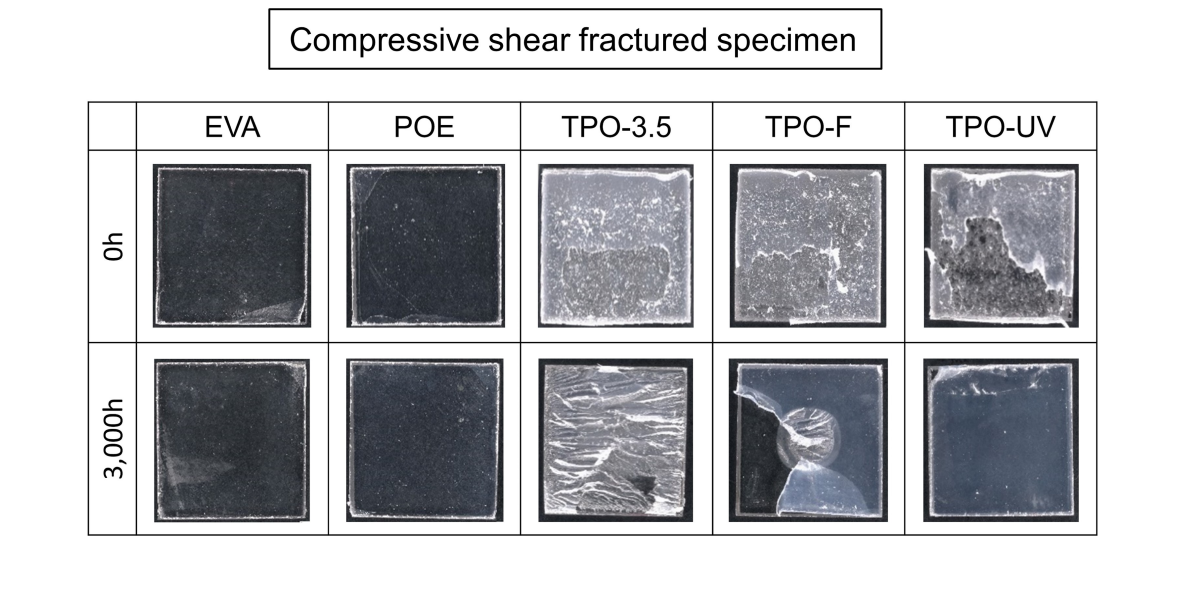

Before compressive shear testing, the experimental specimens were exposed to ultraviolet (UV) irradiation of 40 W/m2, temperatures of 65 C, and relative humidity of 10 % for up to 3,000 h. A visual, optical, mechanical, and chemical analysis of the changes was enabled by using several instruments, including microscopy, UV-visible-near infrared spectroscopy, compressive shear testing, as well as differential scanning calorimetry, Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy.

The team analyzed and ranked the results. They found that the best-performing TPO variation was TPO-3.5, followed by TPO-UV, TPO-F, EVA, and POE. “While the aged and fractured EVA, POE, TPO-F and TPO-UV laminates exhibited carboxylic acid signatures differing in intensity, no carboxylic acid residues were detected on the fractured TPO-3.5 surface,” stated the team.

Furthermore, the TPO-3.5 had a “lower melt flow index”, which translates to “a higher average molar mass” compared to TPO-F and TPO-UV. “For the crosslinked EVA and POE, the test temperature was already within the melting range of the non-crosslinked, polyethylene rich phase of these peroxide crosslinked encapsulants,” the academics specified.

The team concluded that the “obtained results clearly indicate that special attention should be given to the TPO-3.5 encapsulants for double-glass PV modules” in future research. “The next step will be the evaluation of subsequent damp heat and UV aging of TPO-glass laminates on the long-term performance,” said Tiefenthaler, adding that the positive findings on specimen level have to be validated and investigated by upscaling to PV module sizes.

The results of the research were presented in “Effect of UV ageing on debonding of double glass laminates based on different crosslinking and thermoplastic PV encapsulants,” published by Solar energy materials and solar cells. The researchers came from the Johannes Kepler University Linz, Christian Doppler Laboratory for Superimposed Mechanical-Environmental Ageing of Polymeric Hybrid Laminates, and Borealis.

Last year, another research group at the Johannes Kepler University Linz carried out lengthy damp-heat tests on double glass solar modules made with UV-transparent EVA and POE encapsulants for over 10,000 hours, finding several advantages of using POE encapsulants compared to EVA materials.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.