Researchers from China's Harbin Institute of Technology proposed to combine pumped hydro storage systems with compressed air energy storage (CAES) technology in an attempt to address a well-known issue of pumped hydro schemes – dealing with large head variations in hydraulic machinery.

“We have designed a novel pumped hydro compressed air energy storage system integrating pumped hydro storage, compressed air energy storage and hydraulic potential energy transfer technologies,” the research's corresponding author, Deyou Li, told pv magazine. “We have also analyzed the system's composition and operation principle, as well as the thermodynamic model of each module. Its correctness was verified by comparing our results with the existing literature data.”

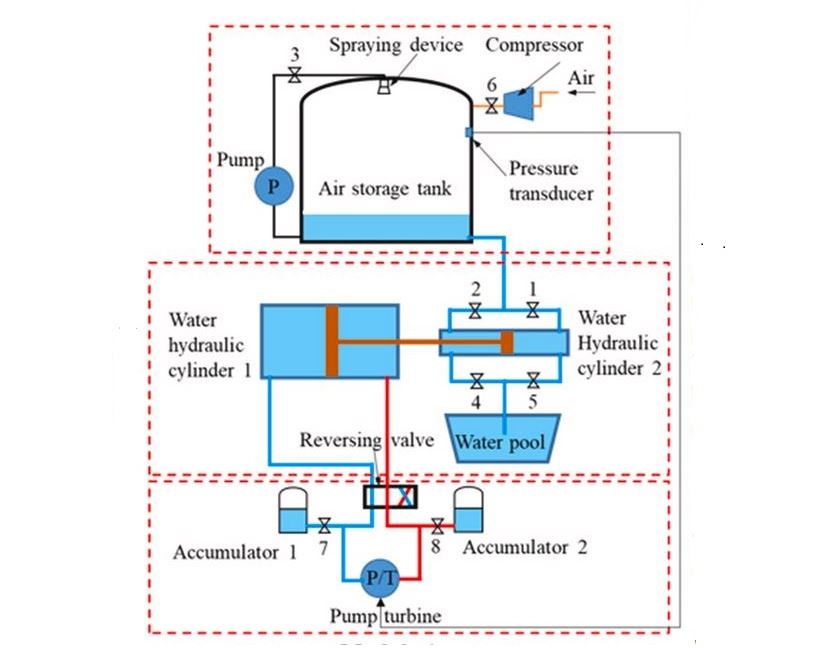

In the paper “Energy and exergy analysis of a novel pumped hydro compressed air energy storage system,” published in Energy, the research group explained that the system works through multi-cycle charging and discharging processes. It comprises a pumped storage unit, a reversing valve, a spraying device, water hydraulic cylinders, an air storage tank, a pump, a water pool, and several valves.

In the charging phase, the system extracts water from the water pool through hydraulic machinery. The water is then pushed into the air storage container for air compression. During discharging, the air inside the air storage container expands, and the water

coming from the container is injected into the hydraulic machinery for electricity generation.

“The proposed system can store and release energy by charging and discharging, enabling it to perform peak-shaving and valley-filling functions,” the academics said. “When the electrical load is small, the surplus electrical energy is absorbed by the pumped storage unit and converted into internal energy of the compressed air for storage. Conversely, the system supplies power to the grid.”

The system also uses a spraying device to enhance heat transfer between the air and water in the tank to achieve near-isothermal compression and expansion.

“When the spray device is not used, the air temperature rises to 36 C during charging and decreases to 6.4 C during discharging,” the group explained. “When spraying, the variation in air temperature under the charging, standby, and discharging conditions significantly decreases. The maximum value of air temperature during charging reduces to 28.4 C and the minimum value of air temperature during discharging increases to 13.2 C.”

The scientists tested the proposed system configuration through a series of simulations and assumed the system to have a capacity of 1 MW. They calculated a charging time of 31.1 minutes and a discharging time of 23.1 minutes.

The analysis demonstrated that the water pressure potential energy transfer module adopted in the system can effectively convert the pressure variation of nearly 1.6 MPa in the air storage tank to a head variation of 58.5 m during pumping and 48.2 m during power generation of the pumped storage. It also showed that the pumped storage unit has the highest energy waste and is the section of the system that needs to be further optimized within a general approach aimed at reducing the system's complexity.

“In future studies, the number of energy transformations in the proposed system will be further reduced,” the researchers concluded. “Subsequently, an experimental platform will be developed to verify the technical feasibility of the proposed system and reveal the effects of key design parameters, such as the initial pressure, termination pressure, volume of the air storage tank, and variable pressure ratio, on the operational performance of the system.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

The chinese are away behind the times as far as this circuit technology. We were designing and applying the regenerative cycle regularly in the mid seventies. The big advantage is it lowers the horsepower requirement which lowers the electricity usage. Payback varies from 1 to 4 years, depending on the size of the application.

We labeled it the charging and unloading cycle as the stored energy is unloaded. Furthermore, we went on to apply a modified system to injection molding machines. In this application we were able to eliminate a twenty horse power electric motor and replace it with a five horsepower electric motor. Another application that we used was in fuel ponds at nuclear power plants. We used the irridated water to drive cylinders for a

shear blade and a side cutter blade to cut up the spent fourteen foot long Zirconium fuel cells. With the spent fuel cells cut into flat plates we could ship fourteen highly radioactive fuel cells for the price of one. They had to be packed in lead caskets and shipped for disposal. The regen system can be modified and applied to many applications.