Researchers at the Hebei University of Technology in China have designed a solar photovoltaic direct-drive refrigeration system with low energy consumption for high heat-flux electronic device cooling.

“The proposed system integrates photovoltaic power generation with direct-cooling and vapor compression refrigeration (VCR),” the research's lead author, Xiaohui Yu, told pv magazine. “The combination of micro-evaporator and direct cooling method can achieve good heat exchange efficiency.”

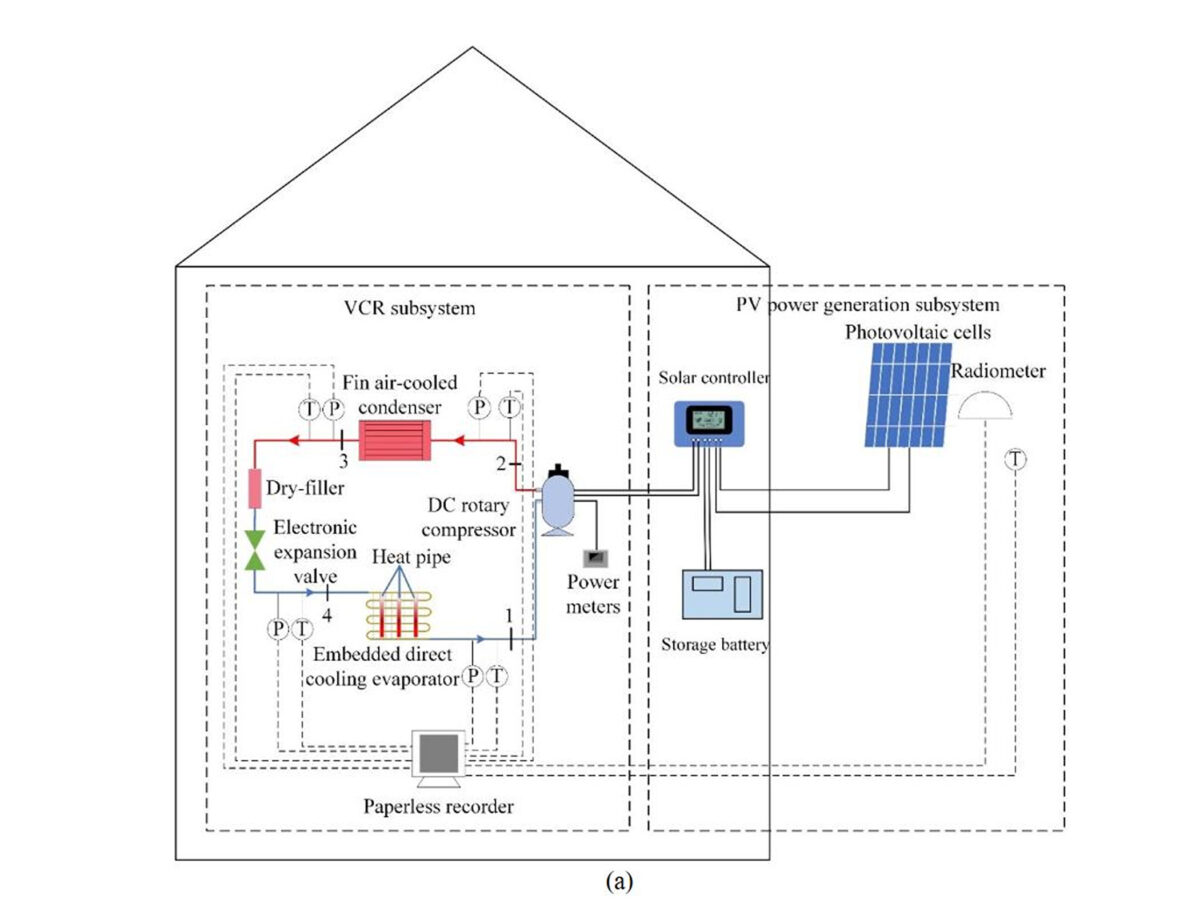

The system consists of two subsystems: a PV unit including a battery and an maximum power point tracking (MPPT) controller; and a VCR unit comprising a DC rotary compressor, a fin air-cooled condenser, an electronic expansion valve, an embedded direct cooling evaporator, and a dry-filler.

In the proposed system configuration, the DC rotary compressor compresses the refrigerant into a high-temperature and high-pressure gas, which is then conveyed into the fin air-cooled condenser to release heat. “The refrigerant becomes the state of gas-liquid two-phase flow with low temperature and pressure through the electronic expansion valve and finally goes to the embedded direct cooling evaporator to absorb the heat of electronic devices,” the researchers explained.

The PV unit powers the DC compressor and the MPPT device is utilized to control the charging and discharging of batteries.

The scientists emphasized that the system's heating power and compressor speed have a great influence on the exergy performance of the VCR subsystem, which they said is closely related to the solar radiation intensity. Exergy is the maximum amount of work that can be produced by a flow of energy as it comes to equilibrium with a reference environment.

The group tested the exergy and economic performance of the system under different operating conditions and found its coefficient of performance reached 8.5 when the heating power and compressor speed were 400 W and 4350 rpm, respectively.

“When the average solar radiation intensity is 776.5 W/m2, the photovoltaic cells of the presented system with operation of 7 h generate 1.81 kW h of electricity, where 24.9% of electricity is consumed on the VCR subsystem,” it added. “The rest is stored and can supply this subsystem to run continuously for 5.3 h without solar radiation.”

The academics described the exergy performance of the PV unit and the compressor as insufficient. “The PV cells have the largest exergy destruction of 1059.4 W, accounting for 91% of the total exergy destruction of the system. Exhibiting the second largest exergy destruction, the compressor reaches 86.3 W and accounts for 7.4% of the total exergy destruction,” they added, noting that increasing the compressor speed from 4350 to 6500 rpm results in a two-fold increase of the exergy destruction of the compressor itself.

Their economic analysis, however, showed that the system is 79.5% cheaper than conventional VCR systems, and that its payback time is around 2.2 years.

“Currently, the embedded direct cooling microchannel evaporator is being tested in our tested bench for long-term operation,” Yu said. “Our work can guide future development and application of this system. In addition, it can promote the development and application of the solar photovoltaic direct-driven vapor compression refrigeration system for heating, cooling and domestic hot water.”

The system was described in the paper “Energy, exergy, economic and environmental assessment of solar photovoltaic direct-drive refrigeration system for electronic device cooling,” which was recently published in Renewable Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

It’s not new at all I have a split system in my house that runs directly off solar panels.