From pv magazine USA

Solar panels are highly recyclable, but the use of thin plastic layers to encase solar cells can cause challenges in recycling valuable materials like silicon or silver effectively.

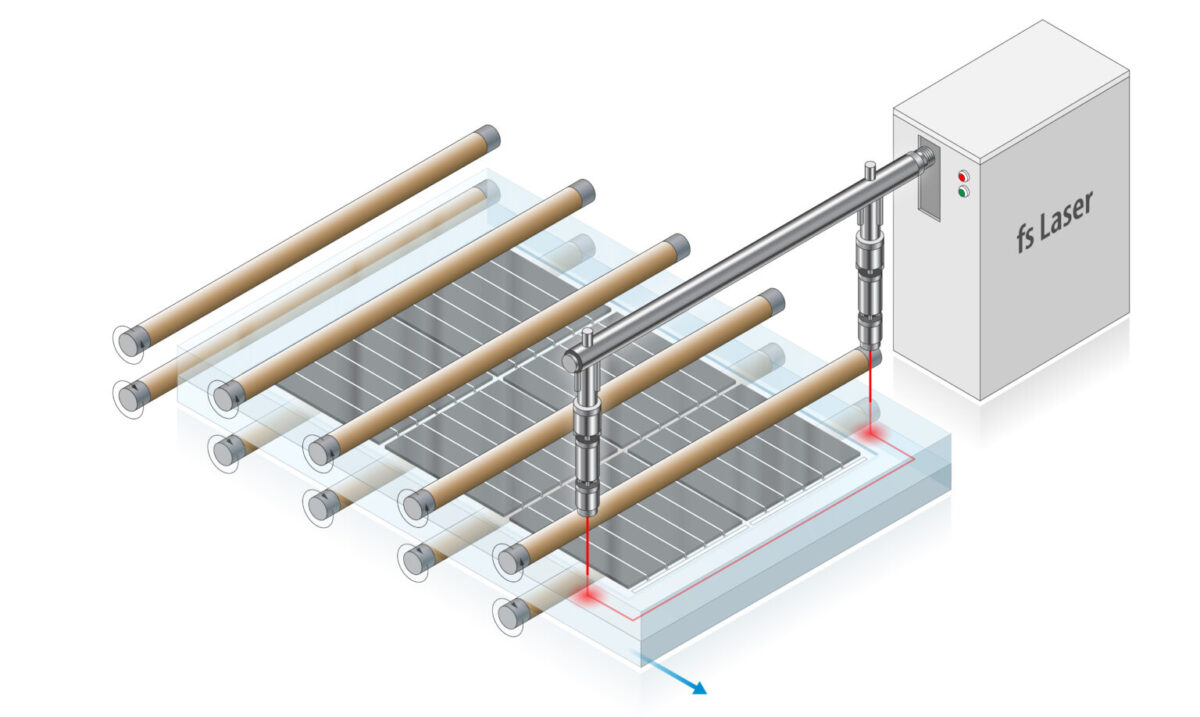

The US Department of Energy's National Renewable Energy Laboratory (NREL) has developed a proof of concept that helps cut the use of polymers by making direct glass-to-glass welds in solar cells.

The method makes use of femtosecond lasers, a type of infrared laser that focuses energy on a very short time scale with a single laser pulse. The laser creates hermetically sealed glass-on-glass welds. Femtosecond lasers are currently used in medical eye procedures like cataract surgery today.

The laser welds would eliminate the need for plastic laminates that make recycling more difficult. At the end of their useful life span, the modules made with laser welds can be shattered, and the glass and metal wires therein can be recycled and the silicon reused.

“Most recyclers will confirm that the polymers are the main issue in terms of inhibiting the process of recycling,” said David Young, senior scientist and group manager for the High-Efficiency Crystalline Photovoltaics group in the Chemistry and Nanoscience department at NREL.

NREL published the study in the IEEE Journal of Photovoltaics. The authors said the laser is cell material agnostic, able to be used with silicon, perovskites, and cadmium telluride, among others, because the heat from the highly focused laser is confined to a few millimeters. The researchers said the welds within the glass are essentially as durable as the glass itself.

“As long as the glass doesn’t break, the weld is not going to break,” said Young. “However, not having the polymers between the sheets of glass requires welded modules to be much stiffer. Our paper showed that with proper mounting and a modification to the embossed features of the rolled glass, a welded module can be made stiff enough to pass static load testing.”

A different type of edge sealing using nanosecond lasers and a glass frit filler was tried in the past, but the welds proved too brittle for use in outdoor module designs. The femtosecond laser welds offer superior strength with hermetic sealing at a compelling cost, said NREL.

The research was conducted through the Durable Module Materials Consortium, which targets extending the useful life of solar panels to 50 years or beyond.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.