Researchers from Austria’s Institute of Polymeric Materials and Testing (IPMT) at the University of Linz have developed a model to improve the quality and consistency of the curing process of ultraviolet (UV)-transparent encapsulants, such as ethylene vinyl acetate copolymer (EVA) and polyolefin elastomer (POE) films.

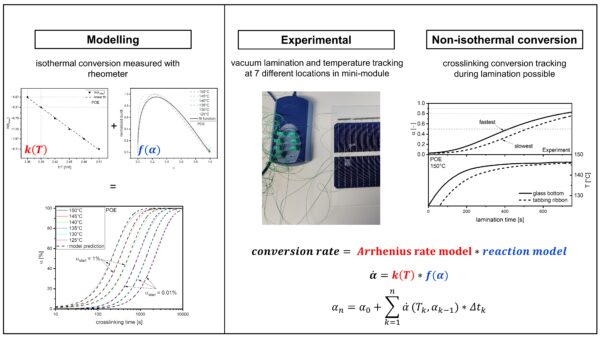

The new model is based on an Arrhenius-type rate equation and a reaction rate model. It was successfully validated under isothermal and non-isothermal conditions.

“The main advantage is the rather simple and reliable approach for optimizing lamination parameters and for identification of critical, insufficiently crosslinked encapsulant spots. The integration of temperature sensors into vacuum laminators would allow it to monitor instantaneously the degree of curing for various module configurations,” IPMT researcher Gabriel Riedl pv magazine.

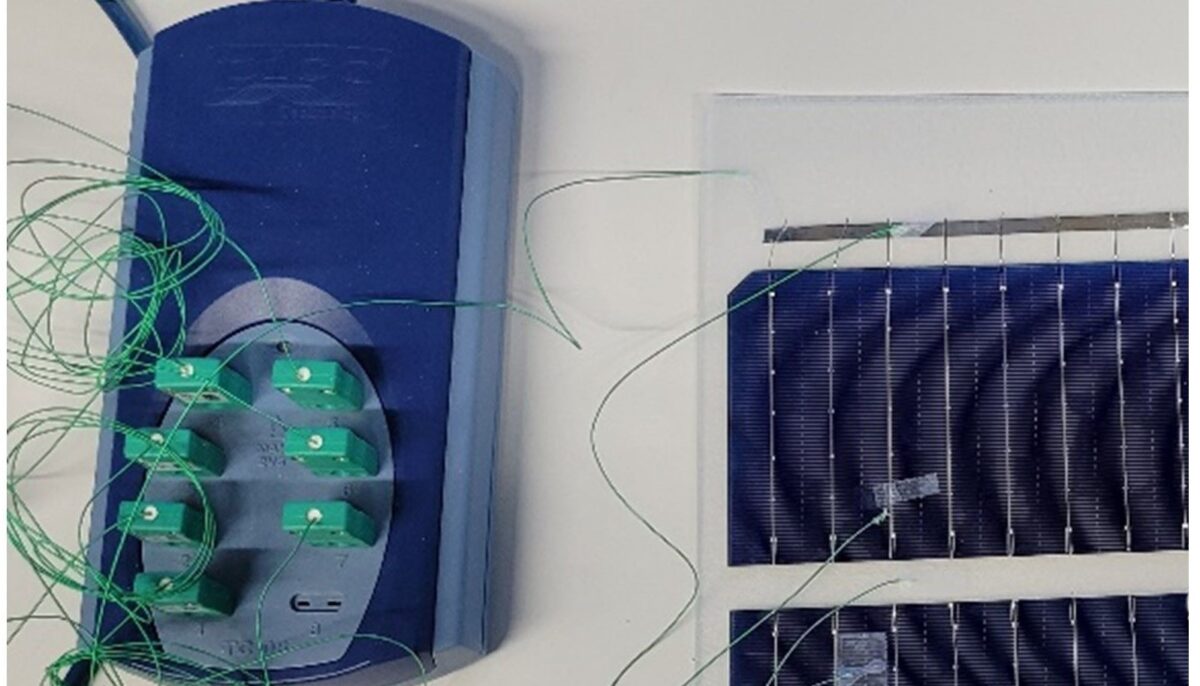

The model was presented in “Modelling the non-isothermal curing kinetics of peroxide crosslinking polyolefin copolymers for photovoltaic module lamination,” published in Polymer Testing. The study involved both experimental measurement and a thermal simulation model. It included the fabrication of mini-modules measuring 300 mm × 200 mm × 7 mm, made with bifacial half-cut solar cells encapsulated in EVA and POE material, and processed in a vacuum membrane laminator.

The pre-evacuation time was 3 min followed by 900 s lamination with an applied pressure of 600 mbar. Subsequently, the laminates were cooled down to 30 C, according to the research team. Temperatures were tracked by positioning seven sensors within the mini-modules which were recorded simultaneously with a data logger.

The curing kinetics assumed a temperature-dependent Arrhenius rate coefficient and implemented a reaction rate model. Validation was performed under both isothermal and non-isothermal conditions with “excellent” agreement of experimental and model data, noted the team.

“The lamination temperature of 150 C led to insufficient curing of POE-based modules after a lamination time of 750 seconds. However, at 160 C the curing rates of the investigated POE grades were comparable to EVA at 150 C and the final conversions were well above 90% for both encapsulants,” said the researchers.

“The implemented non-isothermal curing kinetics model allows for advanced studies of the encapsulants during the lamination process of PV modules and is based on simple physical relationships,” said the team, asserting that it is a “versatile tool for assessment of the non-isothermal crosslinking behavior of peroxide modified encapsulants”, as well as for the development and screening of novel encapsulation material formulations.

The researchers described the simplicity of the model noting how it enables assessment of the conversion degrees of encapsulants in different PV module types just based on the applied lamination temperature profile.

Looking ahead, Riedl highlighted the need to assess the effect of the degree of pre-crosslinking on long-term delamination resistance. “This is of high relevance for double glass modules, which are prone to edge compression during lamination. Additionally, we are open to transferring our know-how to standardization bodies and to contribute to the adaptation of relevant IEC standards,” said Riedl.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.