Researchers from the King Abdulaziz University in Saudi Arabia investigated the use of polymeric coatings for passive radiative cooling (PRC) of PV modules. Radiative cooling occurs when the surface of an object absorbs less radiation from the atmosphere and emits more. As a result, the surface loses heat and a cooling effect can be achieved without the need for power.

“We are currently working on conducting experiments and gathering data with an experimental set-up. We anticipate publishing additional papers on our findings by the end of this year,” the research's corresponding author, Eydhah Almatrafi, told pv magazine.

The group designed and optimized polyethylene terephthalate (PET) and polydimethylsiloxane (PDMS) coating films on commercial PV modules and then simulated their performances under hot and humid conditions. “For applications of PDMS and PET in PV radiative cooling, the polymeric film thickness should be optimized to maximize the radiative cooling effectiveness,” the research group explained. “The film coating thickness affects both the absorption of solar absorption and emitted radiation from the surface.”

The academics tested the two coatings with a film thickness of 200 μm via a simulation conducted on a 12%-efficient solar module with 3.2 mm glass. Their analysis showed that both PDMS and PET coatings were able to increase the transmissivity of glass in the solar bandgap. This, according to the research team, maintains relatively higher thermal emissivity in the first and second atmospheric window bands and enhances the radiative cooling of PV panels.

Within those windows, the results show that the coating increased surface emissivity by 7.5%–8.32% and 3.43%–8.52% compared to glass only for PDMS and PET, respectively. In addition, in the solar cell bandgap, the transmissivity of PDMS and PET layers slightly increased by 0.77%–6.74% with an increase in film thickness.

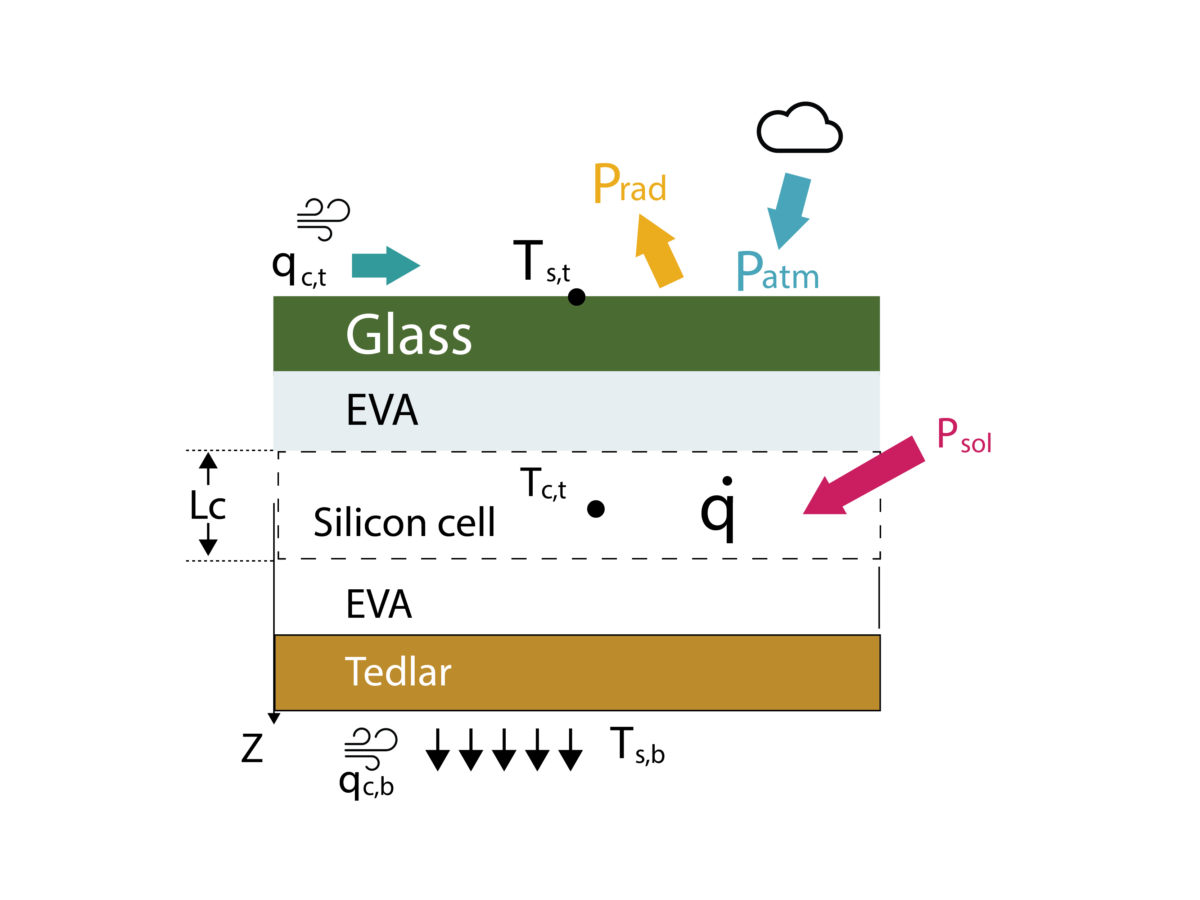

Following this investigation, the academics created a numerical thermal model in MATLAB to analyze the PRC. They considered their effect on the working temperature, electrical output, and power conversion efficiency.

“Surface temperature of PV modules increases linearly with the increase of solar irradiance and relative humidity,” they explained. “The sensitivity of cell temperature to wind speed is relatively high at low values of wind speed and substantially decreases with the increase of wind speed. For low values of solar irradiance, below 300 W/m2, radiative cooling is capable of maintaining the cell temperature at values lower than the ambient temperature.”

Lastly, the scientists simulated the conditions of Jeddah, Saudi Arabia, during the summer solstice, winter solstice, and equinox. The city is characterized by windy weather, high solar radiation intensity, and relatively high relative humidity.

“Temperature reductions of the PV panel by about 10 C below the ambient temperature can be accomplished at summer nights using radiative cooling,” they emphasized. “Adoption of PDMS and PET coatings slightly improves the temperature reductions up to 1.35 C in case of the PDMS and 1.15 C in case of the PET.”

The results were presented in “Polymeric coatings for passive radiative cooling of PV modules in hot and humid weather: Design, optimization, and performance evaluation,” published in Case Studies in Thermal Engineering.

“An economic analysis specific to polymeric coatings was not conducted in our research,” Almatrafi said. “However, the cost of polymers is generally lower compared to metal oxides used in PV manufacturing. Additionally, the economic advantages of energy savings and extended module lifetimes should be considered.”

Radiative cooling was recently applied to solar panel cooling by researchers from Shanghai Jiao Tong University in China, Purdue University in the United States, the Catalan Institute of Nanoscience and Nanotechnology and the Instituto de Ciencia de Materiales in Spain, and the Jordan University of Science and Technology and the Australian College of Kuwait.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.