Researchers at the National Chin-Yi University of Technology in Taiwan have investigated how oxygen distribution may be adjusted in polysilicon production to manufacture wafers with a low concentration of impurities.

They analyzed, in particular, how to regulate the discharge of oxygen from the quartz crucible into the silicon melt during the silicon growth phase in a Czochralski (CZ) puller, which is commonly used for the production of monocrystalline or single-crystal silicon wafers for photovoltaic or semiconductor applications.

“During CZ growth, part of dissolved oxygen segregates into growing crystals, and the remaining oxygen evaporates on the free surface,” they stated. “Understanding and regulating the oxygen transport process during crystal growth is essential for optimizing the crystal quality and yield.”

In the study “Adjustment of Oxygen Transport Phenomena for Czochralski Silicon Crystal Growth,” published in Heliyon, the scientists explained that the walls of the quartz crucible are the main sources of oxygen during the CZ process. This oxygen may then evaporate or be dissolved into the silicon ingots.

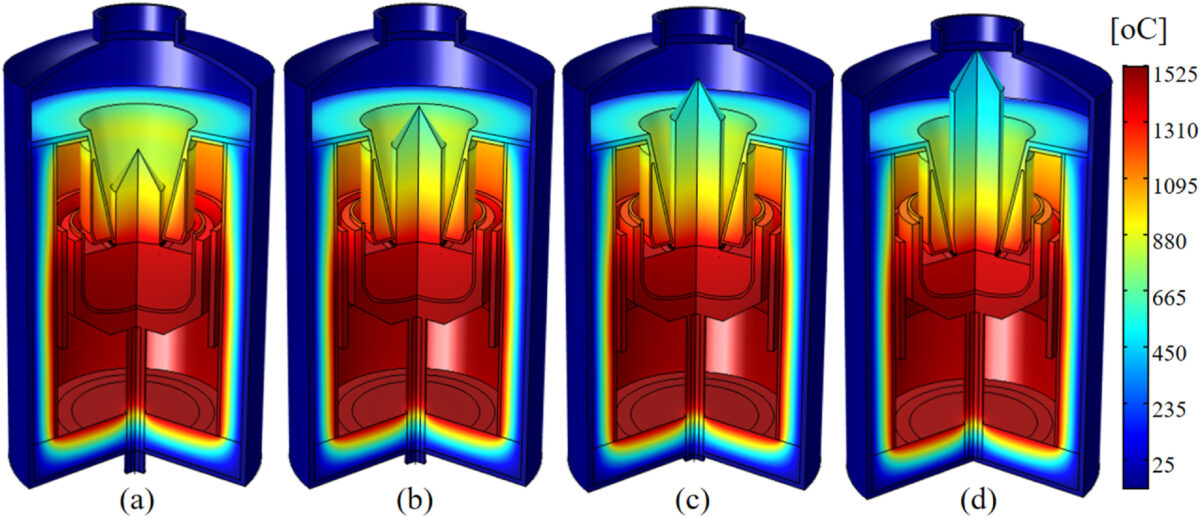

The researchers simulated a CZ process for an ingot with a diameter of 200 mm diameter and a length of 700 mm. They considered using a 20-inch crucible and melt silicon of about 250 kg. They also assumed a variable crucible rotation speed of 1, 2.5, 5, 7.5, and 10 rpm under the same conditions.

This simulation showed that when the crucible speed was raised from 1 to 2.5 rpm the oxygen concentration decreased. “However, experimental observations indicate that the oxygen content actually increased as the crucible speed,” the academics added. They also found that the ratio between the crucible-melt contact surface and the silicon melt-free surface was lower when the crystal length grew.

The team used the Fourier-transform infrared (FTIR) technique, which is generally used to identify chemical bonds in a molecule by producing an infrared absorption spectrum, to confirm the results of the simulation and, in particular, to assess oxygen concentrations in the crystals in the axial directions at ingot centreline.

The academics said their experiment showed that the crucible angular speed affects the oxygen concentration near the crucible wall, which in turn affects the wafers' mechanical and electrical properties.

The proposed simulation approach, according to its creators, may be used in the future to yield more accurate results compared to the existing equations used for current simulations.

“Future research endeavors could delve deeper into studying the interaction between the molten substance and the crucible surface with greater precision,” they said, referring to possible new directions of their work. “Furthermore, investigating the impact of coating crucible quartz with various materials could offer insights into controlling the infusion of oxygen into the molten substance.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.