A group of scientists led by the University of Sydney has fabricated a tandem photovoltaic cell based on copper, indium, gallium and selenium (CIGS) thin-film technology and perovskite. The device utilizes a flexible substrate made of steel instead of glass.

The advantage of the flexible and conductive steel substrate is represented by the fact that the steel itself can act as both a substrate and an electrode for either large-area-monolithic-panel or smaller-area-singular single-junction or multi-junction cell fabrication.

The new cell is an evolution of a 17.1%-efficient perovskite device that another research group of the University of Sidney presented in August. “There is no reason why perovskite-based tandem devices cannot also be demonstrated on steel substrates,” the research's lead author, Anita Ho-Baillie, told pv magazine. “To date, there is only one demonstration of a flexible perovskite−CIGS tandem solar cell, with an efficiency of 13.2%, on a 30 μm thick flexible polyimide foil substrate.”

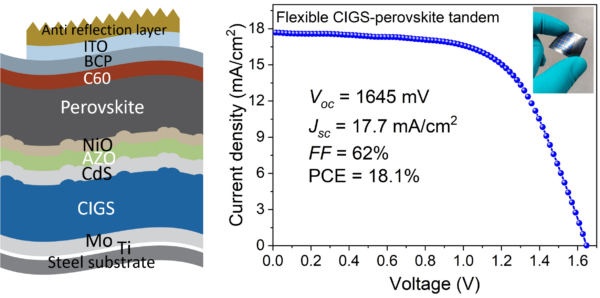

The research group built the cell with a 50 μm thick steel substrate coated with molybdenum (Mo), a CIGS absorber, a cadmium sulfide (CdS) window layer, transparent conductive oxide films made of aluminum-doped zinc oxide (AZO), a hole transport layer (HTL) based on nickel(II) oxide (NiO), a perovskite absorber, an electron transport layer (ETL) relying on buckminsterfullerene (C60), a spacer based on phenyl-C61-butyric acid (PCB), an indium tin oxide (ITO) layer, and an anti-reflection layer.

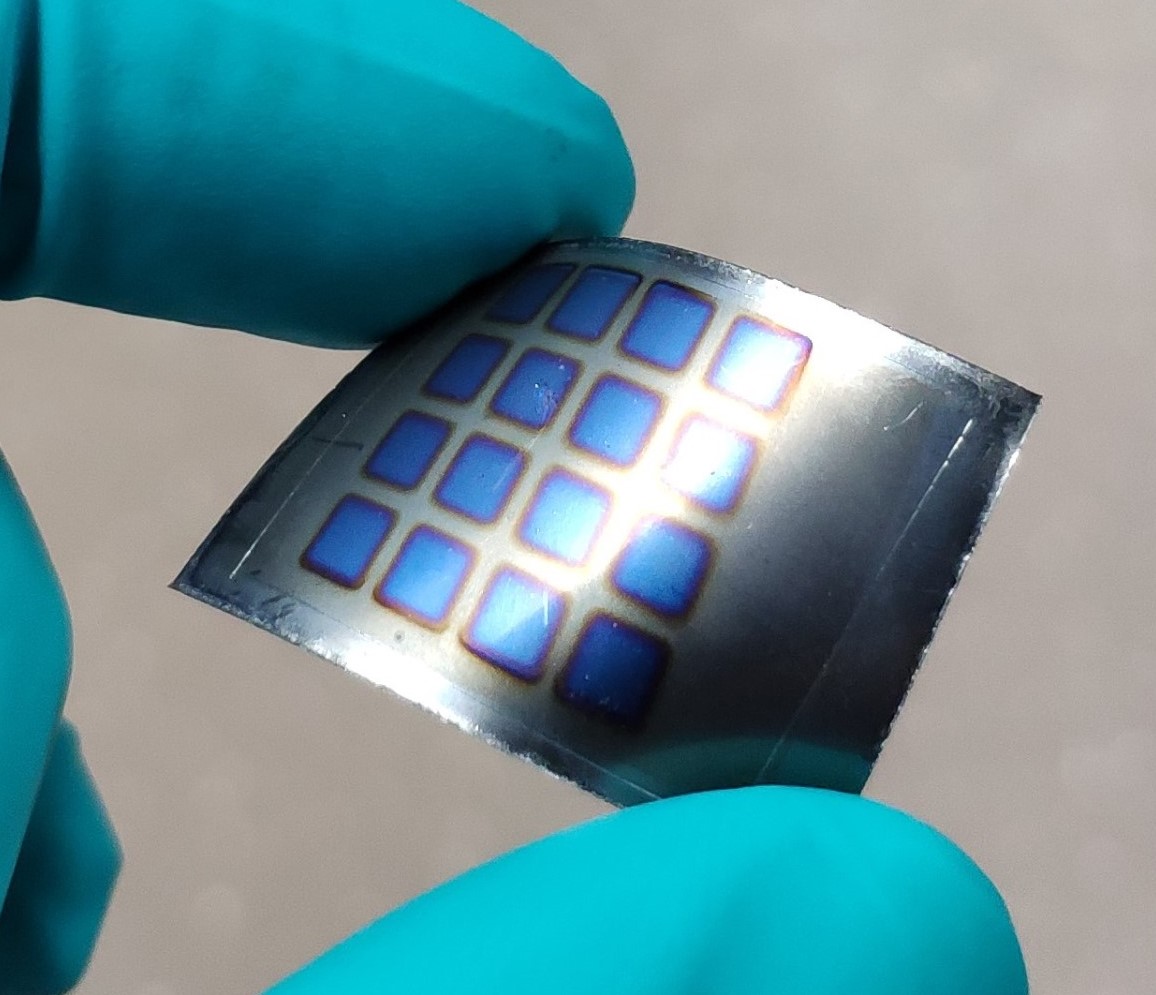

Image: University of Sidney

The scientists deposited the perovskite layer perovskite layer via thermal evaporation and spin coating. “As the substrate used is conductive, metal contact with the rear side of the CIGS bottom cell can be made on either side of the substrate, allowing flexibility for cell interconnection,” they explained.

Tested under standard illumination conditions, the tandem cell achieved a power conversion efficiency of 18.1%, an open-circuit voltage of 1,645 mV, a short-circuit current density of 17.7 mA/cm2, and a fill factor of 62%. This result represents the highest efficiency ever reported to date for a flexible perovskite-CIGS tandem solar cell.

“The substrate used has an added advantage of being conductive, allowing metal contact to be made on either side,” the academics said. “Physical deposition proves to be effective in overcoming the unique challenges associated with irregular surfaces of CIGS cells for tandem demonstrations.”

They described the novel cell concept in the study “Efficient Flexible Monolithic Perovskite–CIGS Tandem Solar Cell on Conductive Steel Substrate,” which was recently published in ACS Energy Letters.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Being made of metal I imagine efficiencies would drop hugely in the sun, but I’m really interested in this technology being flexible and it thin I have a real need for it if it is a more affordable alternative.

By combining the unique properties of perovskite and CIGS materials in a tandem configuration, our solar cells achieve higher conversion efficiencies than traditional silicon-based solar panels, while maintaining flexibility and adaptability to various installation scenarios. The use of a conductive steel substrate enhances the structural integrity of the solar cells, making them suitable for a wide range of applications, including building-integrated photovoltaics, portable devices, and off-grid installations.

With this innovative technology, we are proud to contribute to the transition towards clean and sustainable energy solutions. Our commitment to research and development ensures that we continue to lead the way in solar innovation, driving positive change for a brighter and more sustainable future. Together, let’s harness the power of the sun to create a cleaner, greener world for generations to come.”