Lightricity, which has been developing energy-harvesting indoor PV cells and sub-systems since spinning out of Oxford-based Sharp Laboratories of Europe in 2017, recently added a line of testing equipment for indoor PV cells dubbed Lightbox.

“Our customers wanted equipment to characterize and evaluate different PV cell technologies. We developed the Lightbox to meet their needs as no equivalent product was available,” Lightricity Managing Director Matthias Kauer told pv magazine.

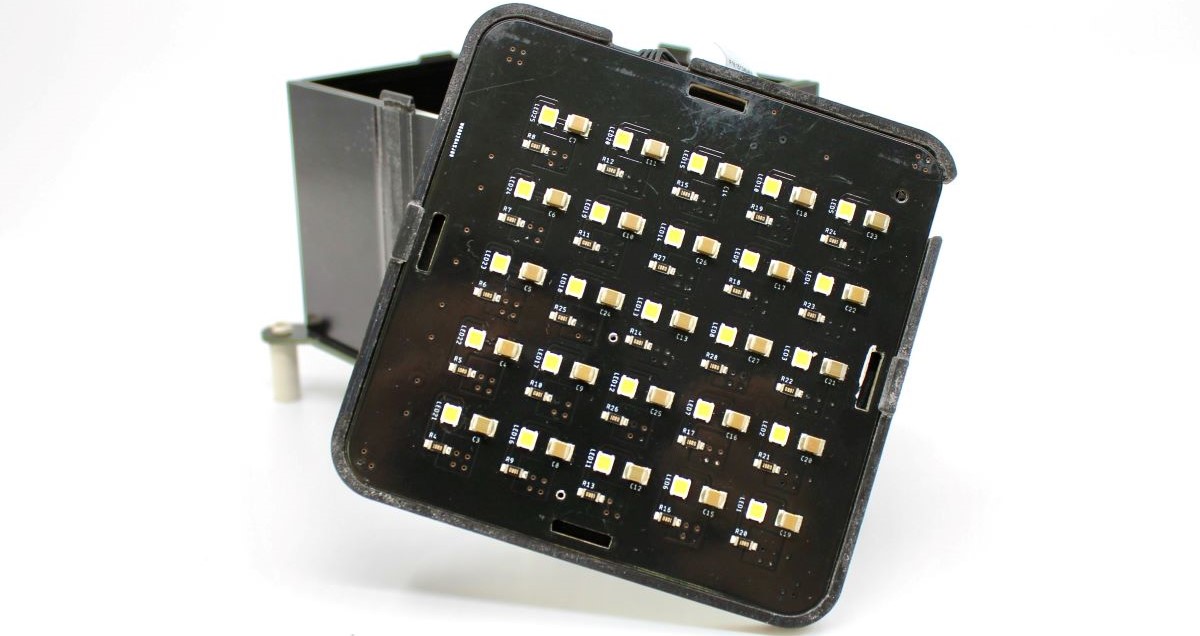

Available in two sizes, LightBox 1.0 and LightBox XL, are measurement systems that emulate indoor lighting environments based on white light emitting diode (LED) technology. They differ in size but share functionality, such as current-voltage (IV) and power-voltage curve acquisition, closed-looped illuminance control via 4 lux sensors, temperature monitoring at up to three different points, and connectivity to computers and source meters such as instruments from Keithley or Keysight, according to Lightricity.

The tests supported include short-circuit current, open circuit voltage, maximum power point power, maximum power point voltage and maximum power point current, as well as fill factor, shunt and series resistance.

Both units have correlated color temperature (CCT) ranges from 2,500 K to 6,000 K with a default of 3000 K, and color rendering index (CRI) is from 70 to 90 with a default of 70.

Light intensities of < 200 lux can be reached with an included diffuser. Light uniformity is ~ 95%, and the manufacturer notes it was tested for both units at the U.K. National Physical Laboratory as part of an Innovate UK collaboration.

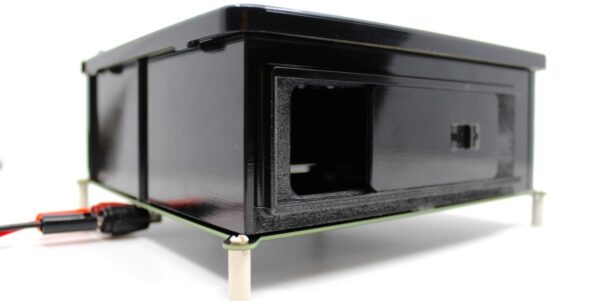

LightBox 1.0 measures 110 mm × 110 mm × 80 mm and has a 5 × 5 array of white LED light with a maximum sample size of 5 cm × 5 cm. Its light illuminance range is 20 lux to 50,000 lux.

The LightBox XL measures 185 mm × 185 mm × 85 mm and has an 11 × 11 array of white LED light with a maximum sample size of 10 cm x 12 cm. Its illuminance range is 50 lux to 40,000 lux.

The Lightbox equipment is available directly from Lightricity. It is designed and manufactured in the United Kingdom.

Customers include indoor PV cell manufacturers, as well as original equipment manufacturers that use PV cells to power their products, such as wristwatches, wearable devices, IoT and sensors, according to Kauer. Research labs investigating the properties and performance of advanced PV devices are also customers.

“We have sold Lightboxes to companies that are developing new PV materials and PV-powered systems in the UK, Europe and North America, as well as universities and research institutes,” said Kauer.

Image: Lightricity

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.