Researchers at Germany's Institute for Textile and Fiber Technologies (ITFT) have designed a pneumatically activable PV façade equipped with solar tracking systems.

“FlectoSol is the first compliant, adaptive façade shading module functionalized on both sides with photovoltaics and, by integrating two actuators in different laminate layers, enabling the movement in two directions required for solar tracking,” the research's lead author, Larissa Born, told pv magazine. “The PV functionalization of FlectoSol aims for an energy self-sufficient shading system. By solar tracking, the energy gain at the façade can be maximized and, at best, energy can be provided for other aspects of building operation.”

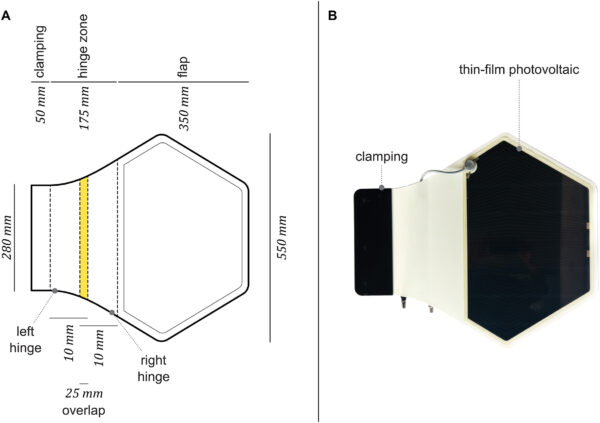

In the paper “Flectosol – A pneumatically activable PV-functionalized façade shading element with bending motion in two directions for solar tracking,” published in Developments in the Built Environment, Born and her colleagues said the PV façade uses two pneumatic actuators integrated in an elastomer hybrid composite based glass fiber-reinforced plastic (GFRP).

The two actuators allow bending in two directions of approximately 90 degrees and are manually slid into the hinge cavities formed by a polytetrafluoroethylene (PTFE) layer in the hybrid composite. “The hybrid composite laminate as well as the pneumatic actuators are manufactured in a hot pressing process,” the scientists said. “In the case of the GFRP-elastomer laminate, a self-adhesive ethylene-propylene-diene(monomer) rubber (EPDM) sealing tape is applied around the laminate setup on the lower steel plate to limit resin leakage.”

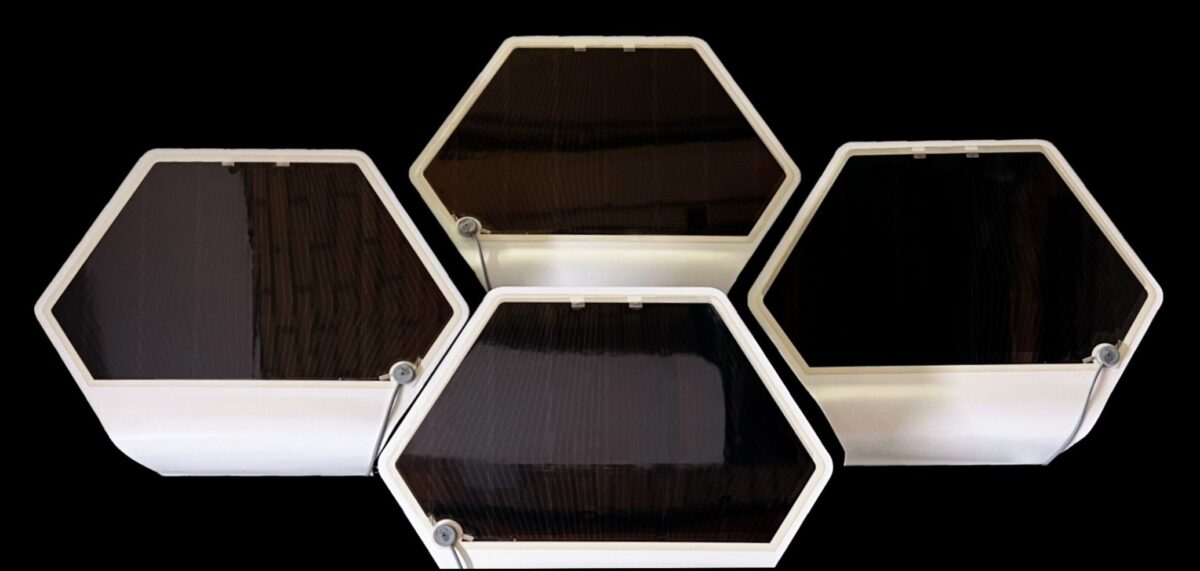

With this technology, the research group built a full south-oriented façade demonstrator covered with octagonal thin-film solar modules that can bend by up to 80 degrees.

The modules are all part of one tracking and pneumatic network, with the upper module alone housing the solar tracking system. “The rest of the modules will actuate accordingly,” the academics explained, noting that each Flectosol system consists of four modules coated on both sides with a PV foil.

They ensured that there was “good” adhesion between the foil and the thermoplastic polyurethane (TPU) surface coating of the fiber-reinforced plastic, and that the PV thin films proved to be functional.

“For proving the possible use in real applications as a façade component, cyclic testing is pending to analyze the fatigue strength and prove the scalability of the hypotheses made here,” they concluded. “Furthermore, the robustness under additional loads as they would occur in outdoor applications such as wind and snow, have to be analyzed.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

More information would be necessary to evaluate the idea as Cost ? LCOE ? longevity ?

A great idea is an idea that flies.