An international group of scientists led by Saudi Arabia's King Abdullah University of Science and Technology (KAUST) has developed an inverted perovskite solar cell incorporating low-dimensional perovskite layers at the solar cell's top and bottom interfaces.

Inverted perovskite cells have a device structure known as “p-i-n”, in which hole-selective contact p is at the bottom of intrinsic perovskite layer i with electron transport layer n at the top. Conventional halide perovskite cells have the same structure but reversed, in an “n-i-p” layout. In p-i-n architecture, the solar cell is illuminated through the electron-transport layer (ETL) side; in the conventional n-i-p structure, it is illuminated through the hole‐transport layer (HTL) surface.

The researchers explained that optimal passivation in perovskite solar cells is typically achieved by applying thin layers of low-dimensional perovskite on top of a 3D perovskite film, and said it is critical to have perfect control over the thickness, purity, and dimensionality of the low-dimensional layers on the top and bottom of 3D perovskites to minimize the energetic losses at these interfaces.

“After extensive testing, we identified the ligand that exhibited the most effective interaction with the 3D perovskites for double-side passivation,” the research's corresponding author, Randi Azmi, told pv magazine.

“Perovskite solar cells with double-side heterojunctions demonstrate a power conversion efficiency of 25.6%, ranking among the top performers in their field. Following accelerated stability test standards, efficiency decreased by only 5% after 1,000 hours of exposure to real-world circumstances. This is critical for stability assessment for commercialization,” added Stefaan De Wolf, KAUST Professor of Material Science and Engineering.

The scientists said that the proposed technique is aimed at minimizing the dissolution of 2D ligands during perovskite solution, in order to strengthen their interaction with the substrate, which they added allows for immobilizing 2D ligands before perovskite deposition.

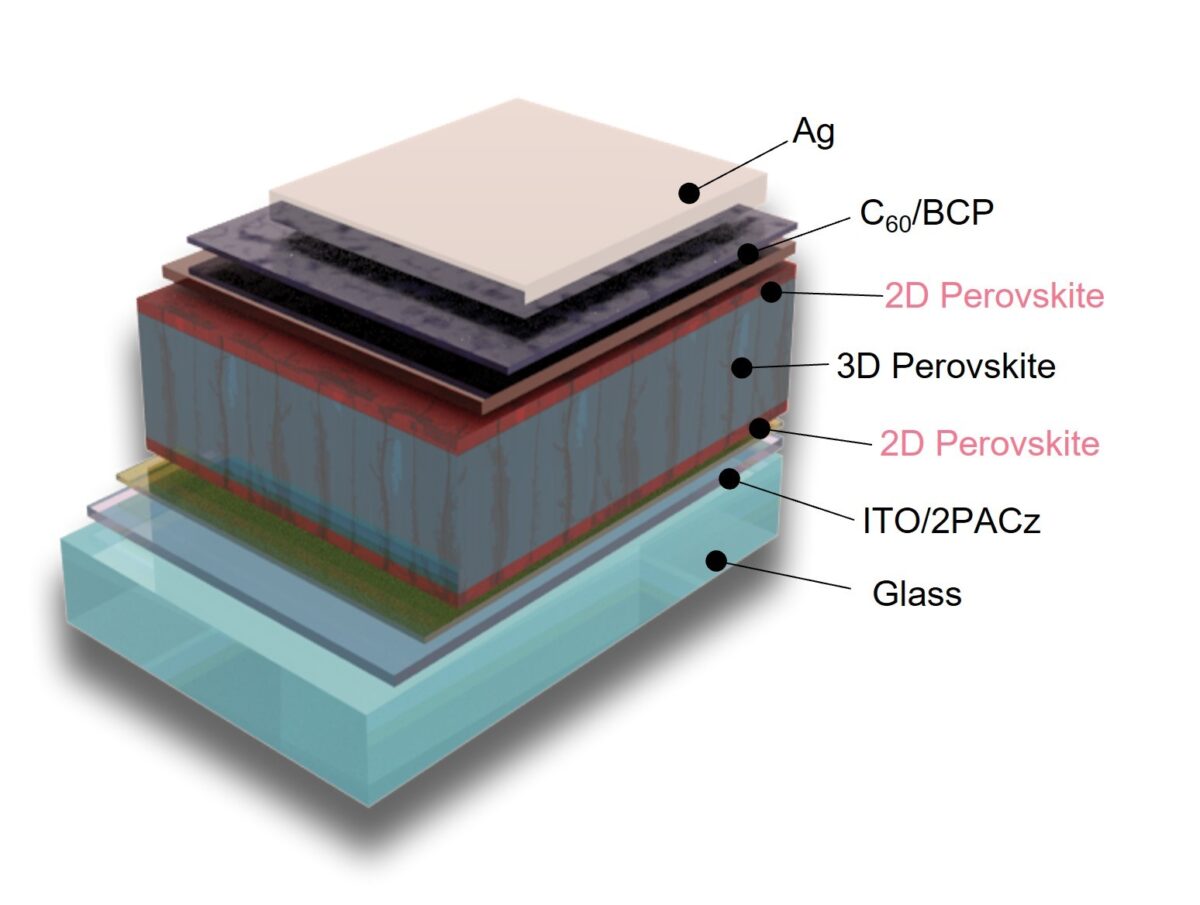

They fabricated a cell with a substrate made of glass and indium tin oxide (ITO), a dimethoxy carbazole (Me-2PACz) layer, a 2D perovskite layer, a 3D perovskite absorber, a 2D perovskite layer, a buckminsterfullerene (C60) electron transport layer, a bathocuproine (BCP) buffer layer, and a silver (Ag) metal contact.

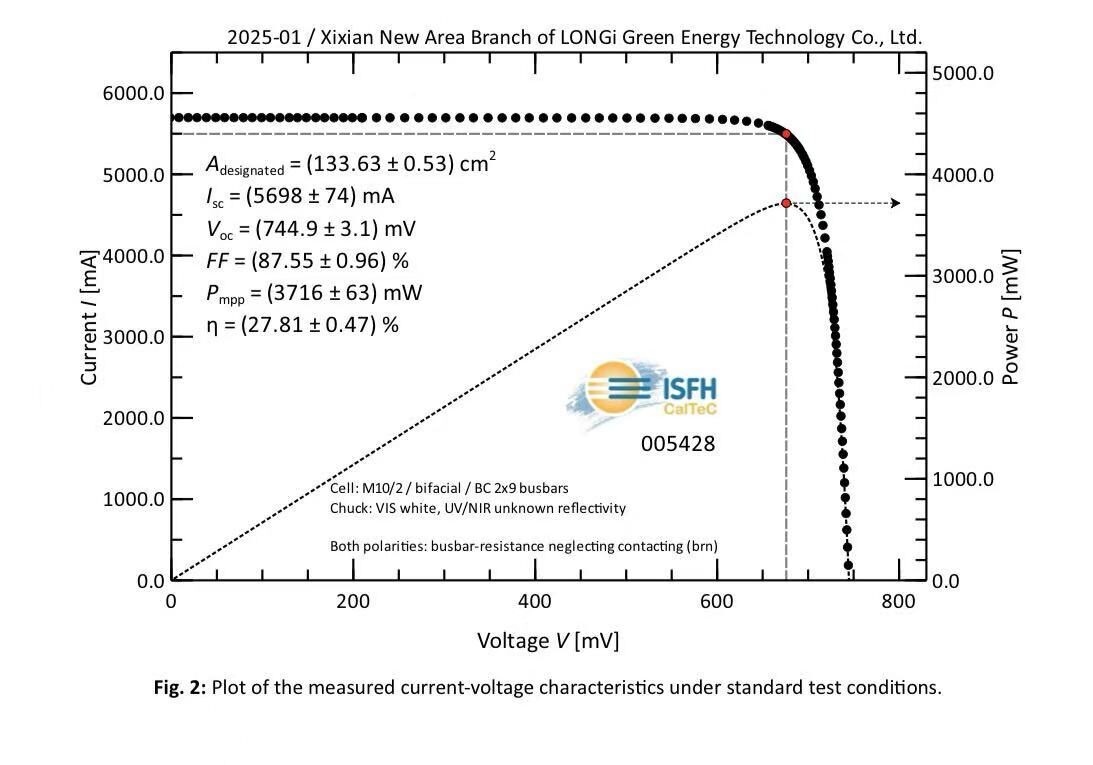

The scientists conducted a series of tests under standard illumination conditions and found the device achieved a power conversion efficiency of 25.63%, an open-circuit voltage of 1.19 V, a short-circuit current density of 24.94 mA cm2, and a fill factor of 85.9%. The performance was also tested by an unspecified “accredited testing center,” which certified it achieved an efficiency of 25.0%, an open-circuit voltage of 1.17 V, a short-circuit current density of 25.0 mA cm2, and a fill factor of 85.7%.

The cell was also found able to retain around 95% of its initial efficiency after 1,000 h and 90% for the same amount of hours under maximum power point tracking (MPPT). “This result indicates that the double-side 2D/3D heterojunctions have a significantly boosted energy barrier for ion migration, which might also improve the perovskite crystal stability,” the research group stated.

The novel cell design was introduced in the study “Double-side 2-dimensional/3-dimensional heterojunctions for inverted perovskite solar cells,” which was recently published in nature. The research group comprised of academics from South Korea's Ulsan National Institute of Science and Technology (UNIST) and the Chinese Academy of Sciences (CAS),

Another research group at KAUST recently announced an inverted perovskite-silicon tandem solar cell with a 1 nm interlayer based on magnesium fluoride (MgFx), placed between the perovskite layer and the hole transport layer (HTL), in order to reduce voltage losses.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.