An international research team has integrated techno-economic heat pump models within a whole-energy system model to investigate the impact of wider adoption of residential air-to-water heat pumps on the UK energy system.

Their analysis was based on data from over 100 commercially available products, with which they developed a thermodynamic and component-cost model of the heat pumps.

“A fully renewable electricity system is expected to require high proportions of wind and solar technologies, an expansion and reinforcement of the power grid and large-scale energy storage,” they said. “These system implications largely depend on the cost and performance of heat pumps, which are in turn influenced by the choice of components, heat demand, and operating conditions.”

Following their market analysis, the scientists grouped the heat pumps based on three different compressor types – reciprocating-piston, rotary vane, and scroll, as well as on ten current and prospective working fluids, and a range of heat exchanger areas ranging from 0.5 m2 and 4 m2. In all cases, the compressor was sized for a maximum thermal output of 10 kW.

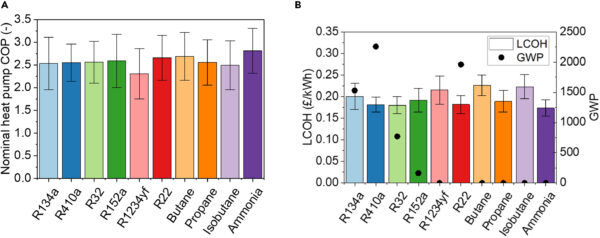

Through this analysis, the group found that, on a heat pump level, the average cost of reciprocating pistons, rotary vane, and scroll compressors is equal to £2,560 ($3,232.52), £790, and £2,690, respectively. The analysis also showed that the coefficient of performance (COP) ranges between 1.6 and 3.8 and that higher COP can be attained with a greater capital investment in components.

Among the ten working fluids, ammonia had the best performance, with the highest COP of 2.8 and the lowest levelized cost of heat (LCOH) of about 0.17 £/kWh. Working fluid R1234yf had the worst COP of about 2.3 and LCOH of 0.22 £/kWh; the highest LCOH of about 0.225 £/kWh was for butane, which also had a COP of about 2.75.

Image: Imperial College London, Cell Reports Sustainability, CC BY 4.0 DEED

The assessment also showed that most high-performance (COP larger or equal to 3.2) and costly (price of more than 750 £/kWth) heat pumps had large heat exchangers and rotary vane or scroll compressors. Most low-performance (COP small or equal to 2.8) and low-cost (price lower than 600 £/kWth) involved small heat exchangers and rotary vane compressors.

To draw implications on the UK's energy system as a whole up to 2050, the resulting data was input into the heat, electricity, and gas infrastructure and technology (HEGIT) model.

“HEGIT is an integrated multi-scale heat, electricity, and gas-system capacity-planning and unit commitment model used to simultaneously optimize the installation and operation strategies of electricity-driven, gas-driven, and heat-driven technologies of the whole energy system,” the academics explained. “The objective of the model is to minimize the total system cost required to reach a net-zero energy system while complying with all environmental objectives and maintaining the security of supply HEGIT.”

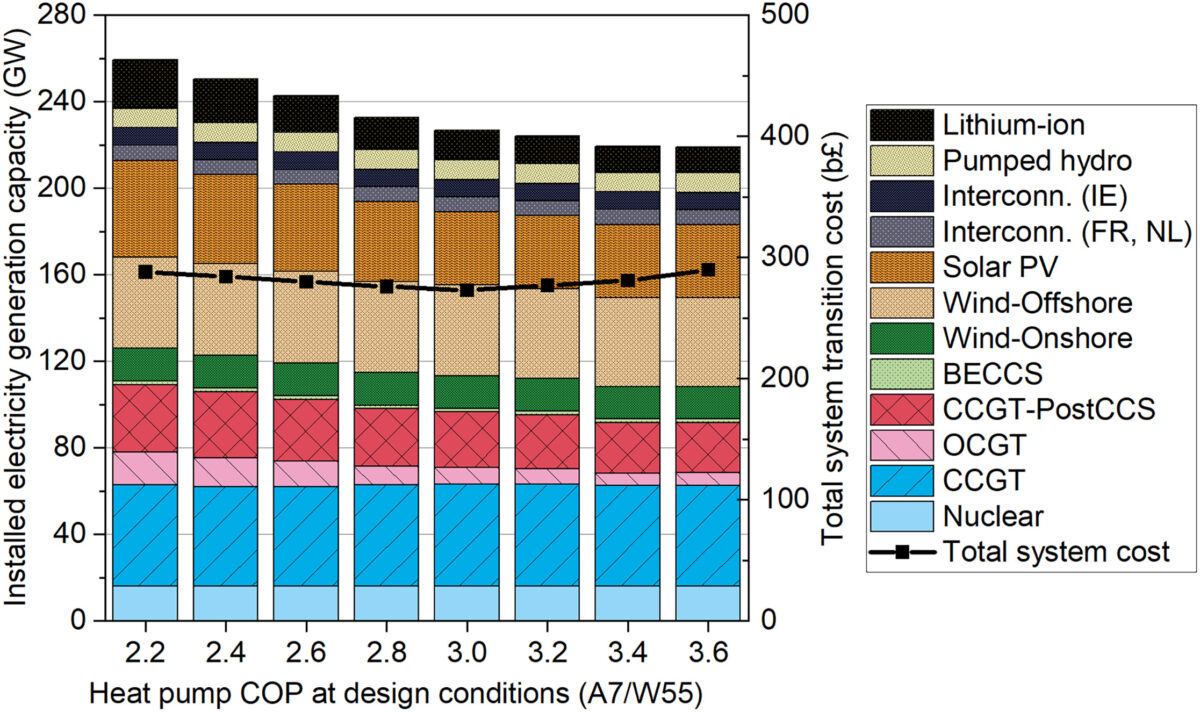

According to the results the scientists yielded from HEGIT, the use of high-performance/high-cost heat pumps can substantially reduce the required electricity generation capacity by up to 50 GW. That is about 20% lower than the low-performance/low-cost units. “This is important, as it means that a large uptake of high-performance heat pumps can significantly lower the power-grid expansion and technology uptake rates that are required to achieve the country’s environmental objectives,” they emphasized.

They also found that different heat pump designs are associated with renewable electricity generation capacity, especially solar PV. “Low-performance heat pumps are associated with up to 9 GW more renewable electricity generation capacity (out of which 7 GW is solar PV) installed in the energy system than high-performance heat pumps,” they said.

In addition, the academics ascertained that while more expensive pumps lead to better COP and less generation capacity, there is a point of diminishing returns. According to them, a compromise between achieving an energy transition and minimizing the required government and end-user investments is found with heat pumps with COP of between 2.8 and 3.2.

“From an energy system’s perspective, the designs that minimize the total system cost have COPs of 2.8, 3, 3.2, and 3 when using R410a, R32, ammonia, or propane as the working fluid, respectively,” they concluded. “Instead of investing in further heat pump COP enhancements beyond these designs, the findings indicate that it is economically favorable to invest in increased centralized energy storage, carbon capture and storage (CCS), and renewable energy generation.”

Their results were presented in the study “Toward optimal designs of domestic air-to-water heat pumps for a net-zero carbon energy system in the UK,” published on Cell Reports Sustainability. The group included scientists from the UK’s Imperial College London and the University of Cyprus.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.