An international research team has developed a new experimental setup to conduct hail impact tests for solar modules. The setup consists of an air compressor, pressure chamber, launcher barrel, and ice ball speed measuring apparatus. The latter is based on an adjustable barrel, and solenoid valve ensuring precise testing in controlled conditions.

The scientists explained the novel setup follows international standards like ASTM 1038-10 and IEC-61215-2. “ASTM 1038-10 provides an extensive approach for evaluating the resilience of photovoltaic modules against external pressures like hail, while IEC-61215-2 offers comprehensive testing standards for crystalline silicon PV modules, including mechanical, electrical, and environmental performance evaluation,” they said.

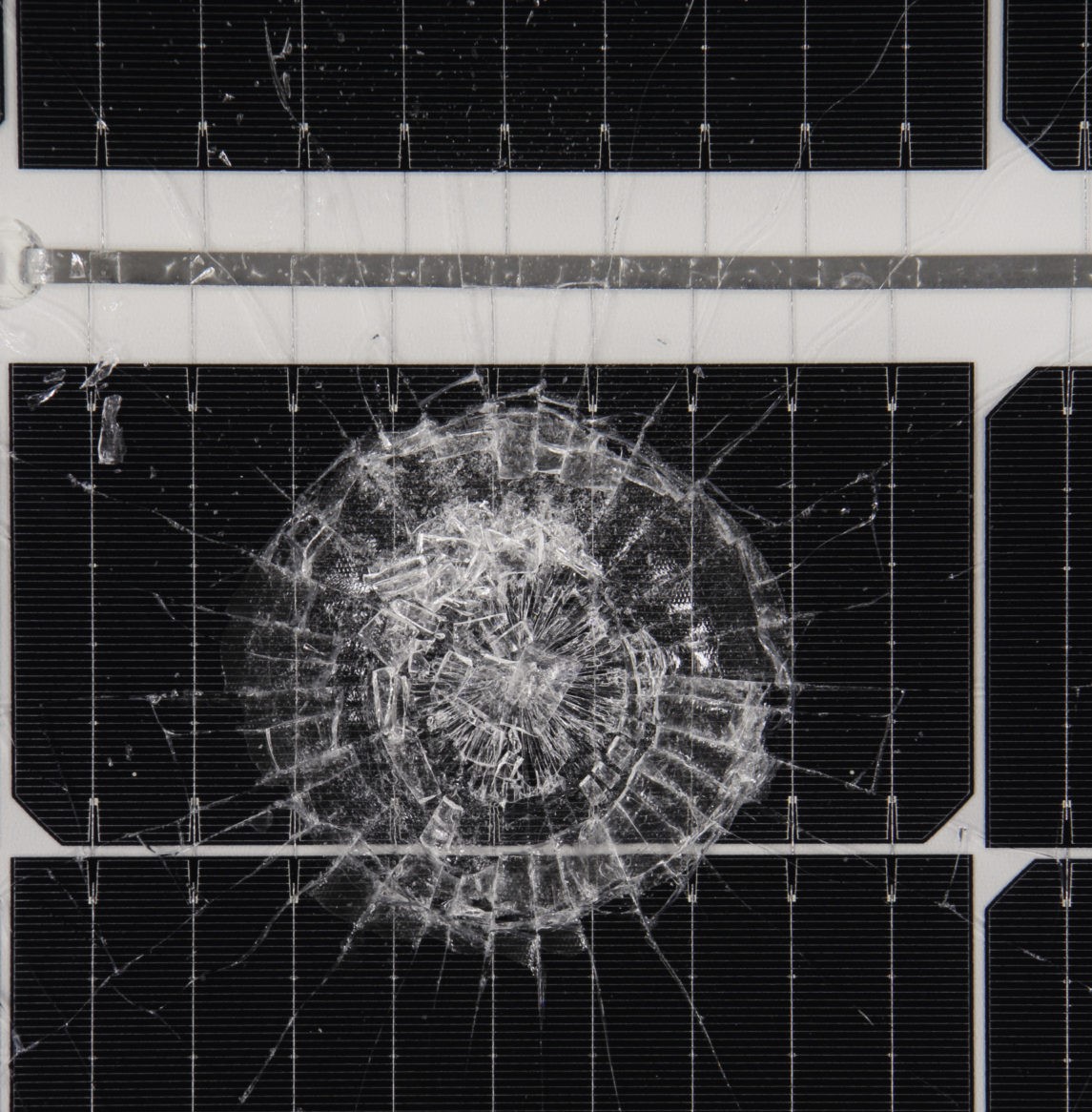

The scientists also used electroluminescence (EL) imaging to identify the crack patterns in the modules before and after hail impact, as well as solar flash testing to quantify the effects of these cracks on panel output. They also adopted a worst-case scenario approach considering that the areas encircled by micro-cracks are electrically isolated from the active cell, which they say sets an upper limit for potential power degradation.

“This methodology allows for the analysis of various influencing parameters,” they added, noting that traditional hail test methods overlook crucial variations related to the impact positions effects on module performance. “This study aims to address these gaps by not only exploring the consequences of micro-cracks on power loss but also investigating the specific influence of impact positions on module integrity.”

The hail tests were conducted on four different 18 W photovoltaic module types fabricated by Pakistan-based Akhtar Solar: a 2-busbars monocrystalline device; a 3-busbars polycrystalline module; a 4-busbars monocrystalline panel; and a 4-busbars polycrystalline module. The modules were connected in forward bias and a current equal to the short circuit current.

The tests showed that, after the panels were hit by the hail balls, the cracks were particularly severe in the polycrystalline modules, with damages spreading all over the surface of the panels. Furthermore, their efficiency was reduced by up to 12.59%, while that of their monocrystalline counterparts dropped by only 4.15%.

“It means the percentage drop in monocrystalline is less than polycrystalline in the same number of busbars,” the researchers stated. “The results also show that PV modules with monocrystalline solar cells are much better in hail resistance than the poly-crystalline solar cells for the same number of busbars.”

pv magazine print edition

Their findings were published in the study “Mechanical integrity of photovoltaic panels under hailstorms: Mono vs. poly-crystalline comparison,” published in Heliyon. “Such insights could pave the way for future innovations in module design, aimed at reducing damage and ensuring sustained power generation in hail-prone regions, thereby advancing the reliability and long-term performance of photovoltaic systems,” they concluded.

The research group was formed by academics from Pakistan's University of Engineering and Technology and the University of Wah, the College of Engineering in Saudi Arabia, and Qatar's Texas A&M University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.