Researchers at the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia have outlined a roadmap for the commercialization of perovskite-silicon tandem solar technologies in an effort to speed up the development of what the industry and the scientific research sees as the most likely candidate to represent the “next-generation” PV products.

In the paper “Pathways toward commercial perovskite/silicon tandem photovoltaics,” which was recently published in Science, the scientists explained that for perovskite-silicon tandem solar modules to become competitive with their PERC or TOPCon counterparts, they will have to show an efficiency exceeding 32 %, and their production cost should not be 30% higher than the cost of producing mainstream products.

The academics assumed a lifecycle of 25 years and different variable module costs for their LCOE comparison. They also found that perovskite-silicon modules must ensure a relative degradation rate of 0.4%/year to become competitive with conventional panels.

“The point we try to make is that it is critical to get annual degradation rates well below 1% relative, else you will need to have very high module efficiencies to start with. So working on stability is of extreme importance to get a competitive LCOE,” the research lead author, Stefaan De Woolf, told pv magazine, noting that this value highlights the importance and urgency of improving perovskite-silicon tandem tech stability.

The research team said future efforts will have to be particularly devoted to developing specific accelerated degradation tests and outdoor tests for accurate field-performance prediction and evaluation.

“The authors suggest geographical testing – akin to personalized medicine for solar cells – to optimize performance for specific locations,” the KAUST said in a statement. “The deployed solar cells must have a lifespan that lasts decades. Accordingly, tests that compress years of wear and tear into a much shorter timeframe are necessary. Understanding degradation rates is crucial for setting competitive prices and warranties.”

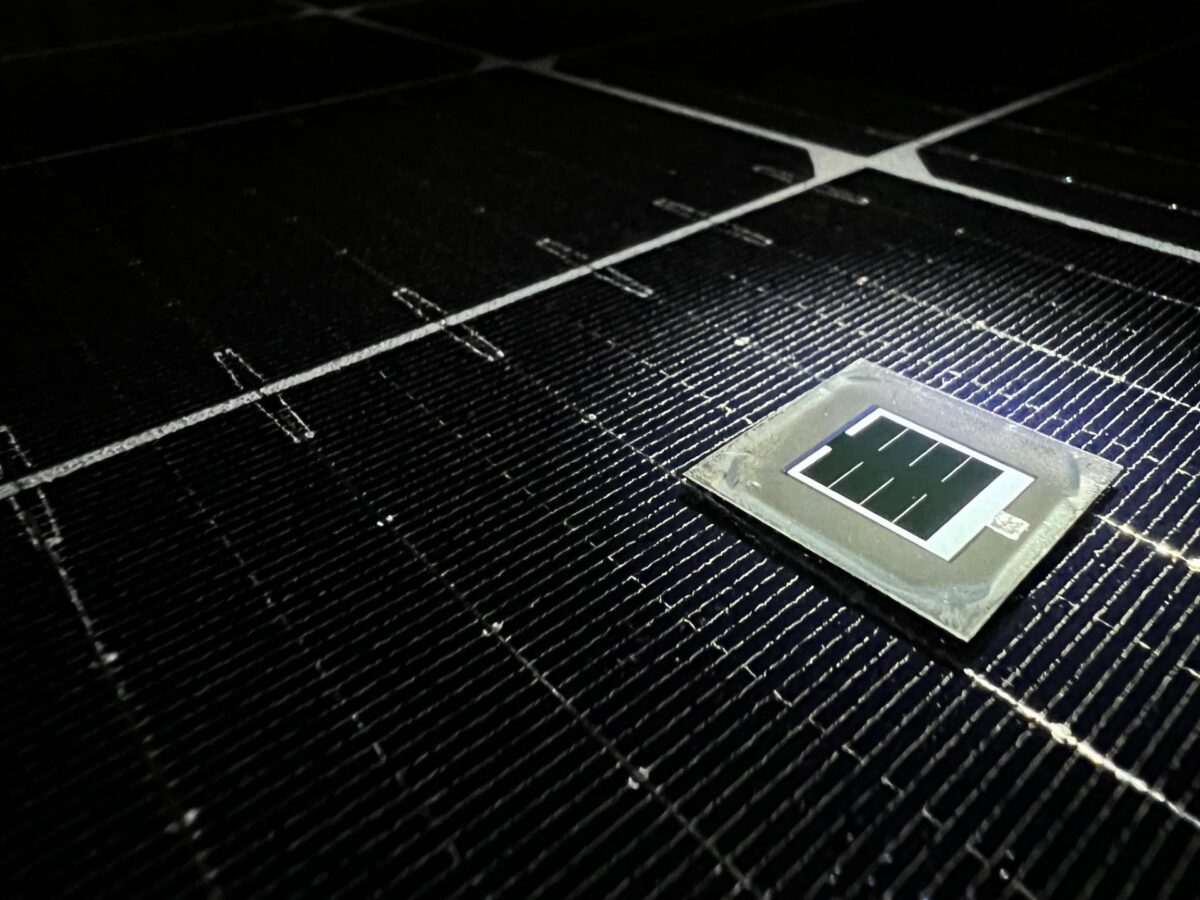

The proposed roadmap describes the current perovskite-silicon tandem cell configurations and their possible advances, as well as all technology used for perovskite film deposition. It also includes insight into module encapsulation and an overview of consortia and companies developing monolithic perovskite/silicon tandem solar cells.

“The market for perovskite-silicon tandems is expected to exceed $10 billion within a decade,” De Wolf said. “In 2023, our laboratory reported two world records for power conversion efficiency, with five achieved globally in the same year, showing rapid progress in perovskite-silicon tandem technology.”

In May, the KAUST achieved a power conversion efficiency of 33.7% for a perovskite-silicon solar cell. A few months earlier, it had announced a power conversion efficiency of 28.1% for a perovskite-silicon tandem solar cell based on textured silicon wafers. In August 2022, it claimed a 26.2% efficiency for a monolithic perovskite-silicon tandem photovoltaic device.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.