Researchers from the Centre of Excellence in Exciton Science based at RMIT, Monash University, and Australia’s national science agency, CSIRO, say they have been able to remove the element of human error with the help of artificial intelligence in rapidly developing perovskite solar cells.

Perovskites are thin-film semiconductors with well-documented challenges in commercialising and scaling up their production. While high efficiencies have been produced in lab conditions, these have proved difficult to replicate in production.

These easily synthesized materials are considered the future of solar cells, with properties ideal for enabling low-cost, efficient photovoltaics. Perovskites are also predicted to play a role in upcoming electric vehicle batteries, sensors, and lasers, among other things.

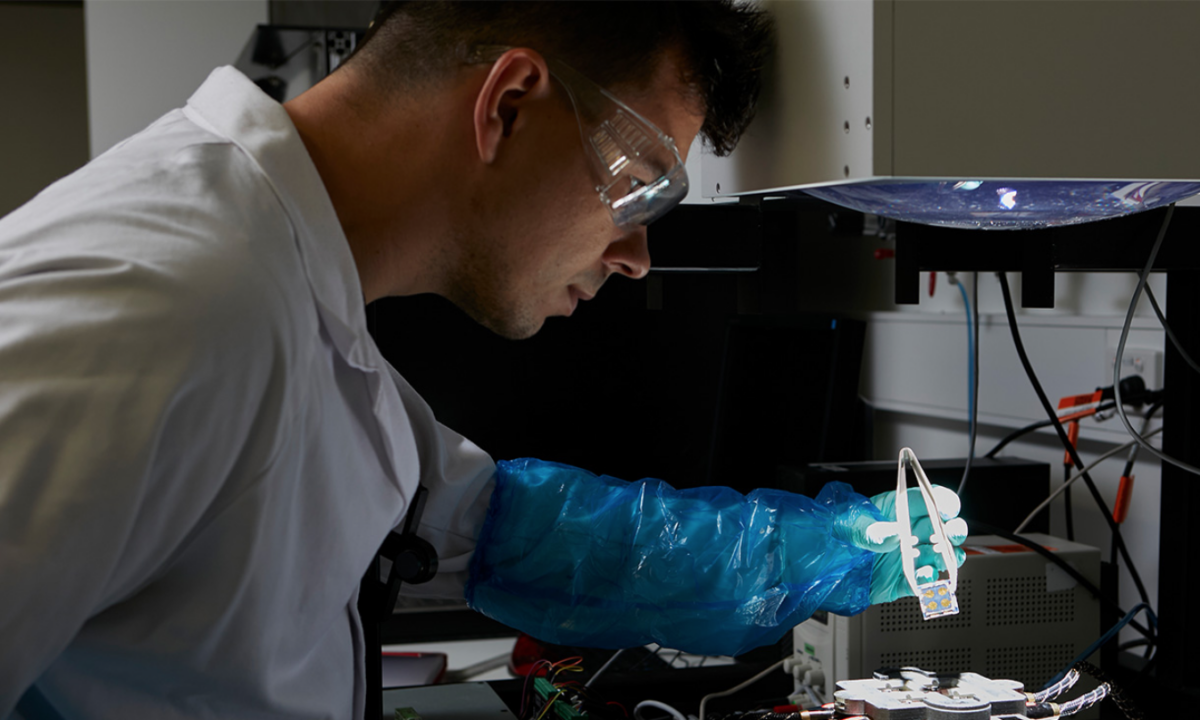

The research team has been able to create reproducible perovskite solar cells with power-conversion efficiencies of 16.9%, which is the best-known result manufactured without human intervention.

“A reproducible 16.9% power-conversion efficiency is better than an irreproducible 30%,” explained Dr. Nastaran Meftahi, lead author of the study that has just been published in Advanced Energy Materials. “What we have achieved is the development of a method for rapidly and reproducibly making and testing new solar cells, where each generation learns from and improves upon the previous.”

The researchers have shown that the model will be capable of predicting huge volumes of promising chemical recipes for new perovskite solar cells.

Dr. Adam Surmiak at Monash University and Professor Udo Bach at the Australian Centre for Advanced Photovoltaics and CSIRO will lead a new facility currently under construction to run the new model automated system for solar cell manufacturing.

“Critically, our machine learning model represents the starting point for further optimisation, both in terms of power-conversion efficiency and stability,” Meftahi said, adding that this machine-learning model and automated system has the potential to process data and run tests on other types of solar cells, including those made with silicon or organic materials.

“We are keen to work with partners in industry to further test and prototype our work so that it can be possibly commercialised in a range of applications,” she said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This is a great achievement. I Would love to get more information on this product and possibly implementing into some projects here in the US.