A group of scientists led by the Research Institute of Industrial Science and Technology (RIST) in South Korea has assessed the adhesion of steel plates and encapsulants made of ethylene vinyl acetate (EVA) or polyolefin elastomer (POE) for future building-integrated photovoltaic (BIPV) applications.

The researchers demonstrated, in particular, a method to increase the adhesion performance of EVA and POE on steel structures.

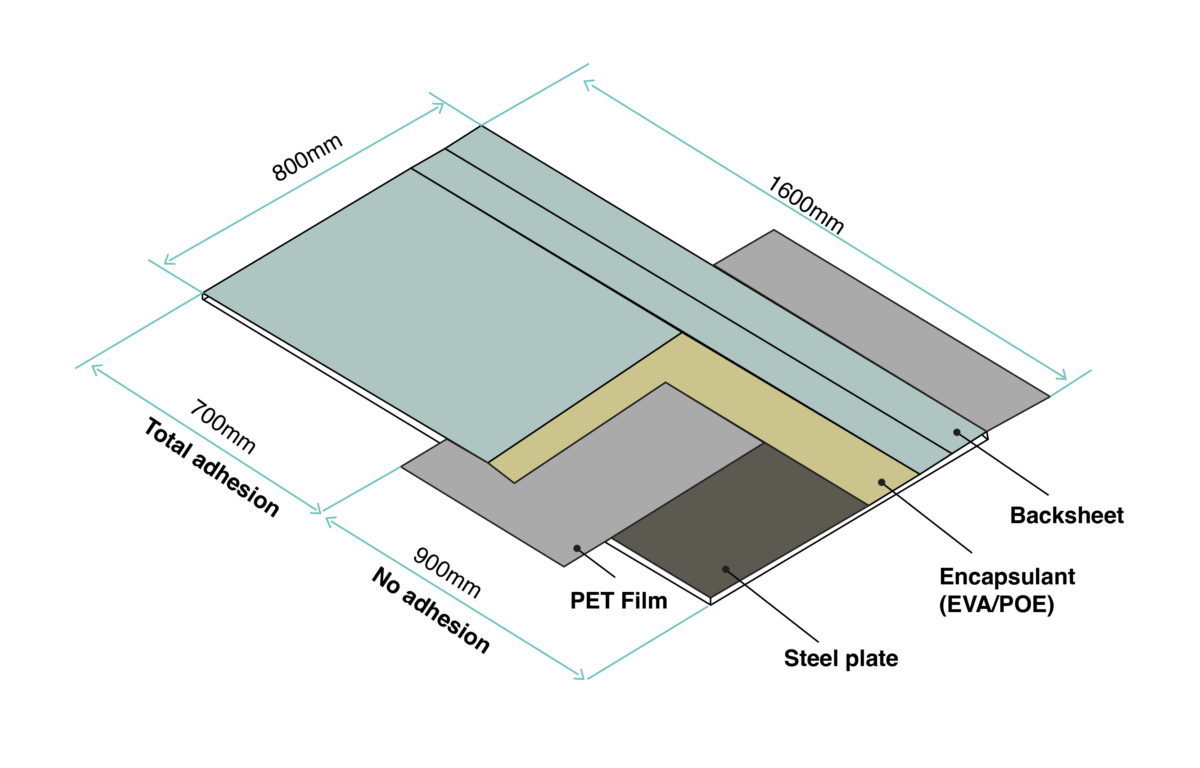

“We replaced the back side glass with a steel plate. So the stacked structure of the PV module would be glass/EVA/cells/EVA/steel,” the research lead author, Young-Su Kim, told pv magazine, noting that his team also improved the lamination process and applied a surface treatment to the steel plates.

The team studied the adhesion performance of twelve samples with the proposed configuration in standard peel force tests. The samples were prepared as follows, six EVA and six POE, with half again processed at 170 C and 150 C. Furthermore, the surfaces of colored steel plate samples were “scratched” through a “mild” and “strong” process, respectively, or were left unscratched.

The results of the EVA tests confirmed earlier research that showed that the adhesion strength of EVA is increased by raising the lamination temperature by 20 C. As for the samples combining EVA laminated at 150 C in combination with treated steel surfaces, the team observed a 20-fold increase in the “strong” scratched samples in comparison to non-scratched samples. “Meanwhile, in the case of lamination at 170 C, even mild scratching resulted in a significant increase in adhesion,” said the researchers.

As for the POE encapsulants, the lamination temperature was not as critical to adhesion performance as the surface treatment. The researchers said that in the case of POE, even a surface without scratches exhibited strong adhesion. “As the intensity of scratching increased, adhesion also improved, reaching a notable 6.1 N/mm under conditions of pronounced scratching. This level of adhesion was in proximity to that observed between EVA and glass surfaces,” the researchers explained.

The team sees the research as a step towards being able to use colored steel plates in BIPV modules instead of glass or conventional backsheets. The so-called glass-to-steel (G2S) design addresses some of the challenges of using PV on building facades, note the researchers. For example, G2S modules have potentially superior aesthetics, greater durability, and a fire resistance performance at least as good as dual glass modules.

When asked about the next steps, Kim said that the team has fabricated some G2S-type modules based on the same split in the research paper for further testing. “We are testing some reliability tests such as damp heat and thermo-cycle tests. We expect to achieve higher reliability in the test group than in the controlled group,” he said.

The details of the work are presented in the study “Analysis of adhesion characteristics of steel back plates and encapsulants for fire-proof BIPV modules,” published in Results in Engineering.

The project team also includes scientists from the Korea Institute of Industrial Technology and Korea University.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.