Last year, CATL produced 37% of the world’s EV batteries and 43.4% of energy storage batteries for a grand total of 289 GWh and 2023 is shaping to be another landmark year.

According to South Korean research firm SNE Research, CATL cemented its domination of the global EV industry in the January-August period this year with 37% market share, followed by second-ranked BYD with 16%. Its sales outside of China reached 27.7%, up by 6.9% year-on-year.

As pv magazine learned from CATL, in the third quarter of 2023, the company’s battery sales volume stood at around 100 GWh, with BESS accounting for nearly 20%.

According to CATL, innovation is the key driver of its growth. In the first three quarters of 2023, CATL invested about 14.88 billion yuan ($2.1 billion) in R&D.

As of the first half of 2023, CATL’s issued and pending patents have reached 22,039 worldwide, and it has contributed to the drafting or amending of over 110 industry standards at home and abroad.

With R&D centers in Ningde, Liyang, Shanghai, Xiamen and Munich, which employ more than 17,998, CATL is managing to stay at the forefront of development in energy storage technologies.

Some of its key breakthroughs include the development of liquid-cooling energy storage solutions with long service life and high level of safety.

pv magazine roundtables Europe 2023

Session 8 | Dec 6, 10:30 am CET, virtual | All about storage: Price, materials, tech, and new revenue

As the energy storage sector continues to grow and mature, understanding costs and revenue opportunities is the highest priority for many stakeholders. As lithium-based batteries continue to dominate the sector, the outlook on costs, materials, and technology remains the key question. In addition, we will also explore the most attractive markets and revenue opportunities for BESS in Europe, beyond the wins in transferring energy from generation to times of demand.

Experts:

- Evan Hartley, Benchmark Mineral Intelligence

- Max Reid, Wood Mackenzie

- Aaron Wade, Exawatt

- Winfried Wahl, Hithium Energy Storage Deutschland

- Ryan Alexander, Aurora Energy Research

- Steven Coppack, Timera Energy

Furthermore, CATL has worked on low lithium consumption anode, which reduces the consumption of active lithium content while improving the stability of the anode material surface and structure as well as self-repairing electrolyte, which improves cell storage and cycling performance.

It has also achived big results with its passivated cathode with the help of doping and coating techniques to reduce side reactions in high-voltage scenarios.

As CATL underlines, “ensuring the safety of energy storage batteries poses far greater challenges than those for EV batteries, as it requires a much higher level of consistency in manufacturing as well as innovation in cell and system design.”

By deploying advanced technologies including 5G, flexible automation and IoT, CATL has achieved a defect rate of DPPB (single defect rate per billion) for its cells, which is the top in the industry.

As for the next frontier in development of lithium-iron-phosphate (LFP) batteries, today's leading energy storage technology, CATL’s goal is further optimization of product performance including service life, power rating, and direct current resistance (DCR), which will in return pave the way to more competitive batteries for its customers.

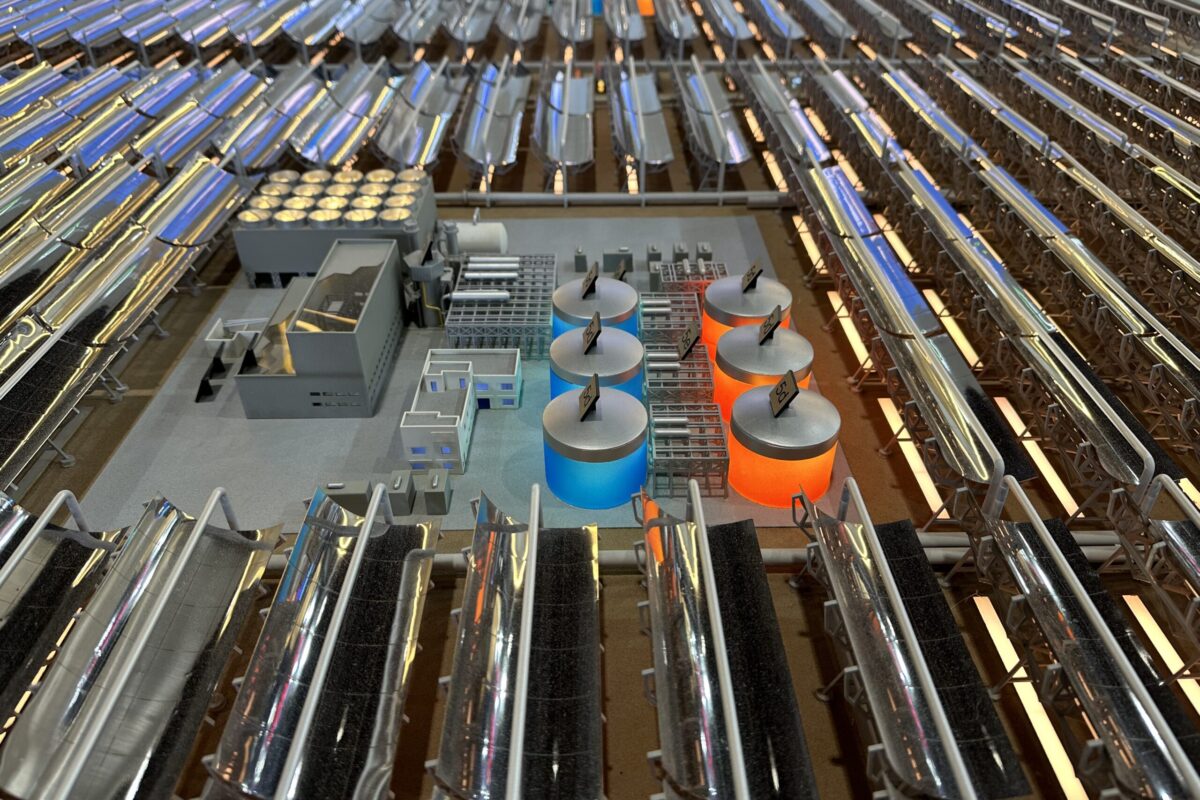

In terms of cycle life, CATL has already made and deployed batteries capable of cycling 12,000 times. In 2020, CATL deployed the 12,000-cycle ultra-long-life batteries at the Jinjiang 100 MWh Energy Storage Power Station, which has been operating safely ever since, according to the company. CATL’s stated goal is to increase the cycle life to 18,000 cycles.

Beyond lithium-ion stationary storage technology, CATL is also at the forefront of development of the sodium-ion chemistry. It sees the technology as compatible and complementary to lithium-ion batteries.

CATL says it has successfully built the basic industry chain for sodium-ion batteries and established the mass production capacity, noting that the production volume and shipment scale depend on the implementation of customers’ projects.

According to CATL, there are still many conditions that need to be met in the market before the large-scale commercial application of sodium-ion technology. “We hope that the whole industry will work together to promote the development of sodium-ion batteries,” company representatives say.

In 2021, CATL rolled out its first generation sodium-ion battery with an energy density of 160 Wh/kg and promised an increase to 200 Wh/kg for the next generation. In April, it confirmed that Chinese Chery will become the first automaker to use its sodium-ion battery tech.

This year, CATL has also signalled that it is setting a foot into the emerging field of long-duration energy storage. In November, the manufacturer announced a 10 GWh supply deal inked with Australian renewable energy investor Quinbrook, which will initially involve the delivery of 1 GWh of CATL’s latest outdoor container LFP solution called EnerC Plus.

It also said that the partners will work closely together to assess the viability of “CATL's groundbreaking 8hr charge and 16hr discharge energy storage solution” for use on the Sun Cable Project located in Australia's Northern Territory, which is expected to include up to 20 GW of solar and up to 42 GWh of battery storage.

In the EV sphere, CATL’s major announcement this year was the development of the “condensed matter” battery, a type of semi-solid state product with condensed electrolyte and new anode and separator materials, will have an energy density of up to 500 Wh/kg.

This was preceeded by the launch of Qilin battery in 2022, the third generation of its cell-to-pack technology, claiming the highest integration level to date. With a record-breaking volume utilization efficiency of 72% and an energy density of up to 255 Wh/kg, Qilin is capable of delivering a range of over 1,000 km and equating to a five-minute hot start and ten minutes of charging to get from 10-80% state of charge.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Great insights on CATL’s innovations and strategies! It’s fascinating to see how they’re maintaining their leadership in the battery industry. The focus on sustainability and efficiency will definitely shape the future of energy storage. Looking forward to more updates on their projects!