Scientists from the Islamic University in Bangladesh have designed a cadmium telluride (CdTe) solar cell that can purportedly achieve a high level of photon absorption.

The researchers used the SCAPS-1D solar cell capacitance software, which is a simulation tool for thin-film solar cells that was developed by the University of Ghent in Belgium, for simulating and modeling the solar cell performance.

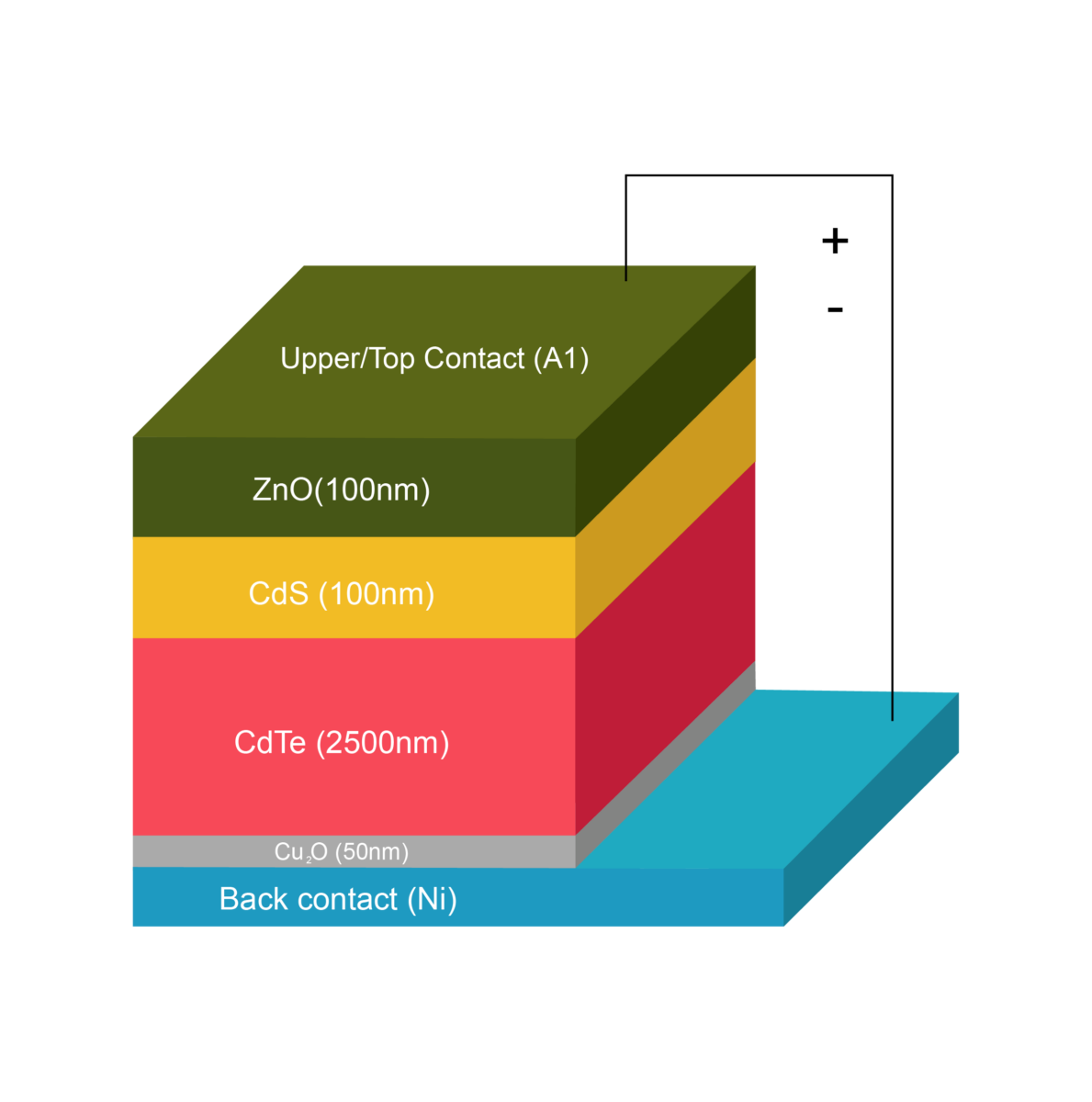

The solar cell design comprises a zinc oxide (ZnO) transparent conductive oxide (TCO) window layer, a cadmium sulfide (CdS) buffer layer, a CdTe absorber, an electron reflected-hole transport layer (ER-HTL) based on cuprous oxide (Cu2O), and upper/top and back contact materials made of aluminum (Al) and nickel (Ni).

In the proposed cell configuration, both the AI upper/top contact and the Ni back contact provide a low-resistance electrical connection and the ZnO window layer, which reduces light reflection, serves as a TCO layer, thus increasing cell efficiency. The back metal contacts act as the electrode responsible for collecting and transferring electrons generated to the external circuit by the absorber layer.

“To achieve the best performance, it is recommended to set both the acceptor and donor densities for the absorber and buffer layers at 10 cm3,” the scientists emphasized. “These densities can be achieved with a window and buffer layer thickness of 100 nm and an absorber layer thickness of 2500 nm.”

Simulated under standard illumination conditions, the PV device achieved a power conversion efficiency of 31.82 %, an open-circuit voltage of 1.4811 V, a short-circuit current of 28.682434 mA/cm2, and a fill factor of 74.91%.

“This level of PV efficiency outperforms other research reports by a significant margin,” the group stated. “Additionally, the proposed structure exhibits a high level of photon absorption, with nearly 100 % quantum efficiency at visible wavelengths.”

The solar cell design was introduced in the study “Effect of various layers on improving the photovoltaic efficiency of Al/ZnO/CdS/CdTe/Cu2O/Ni solar cells,” published in the Journal of Alloys and Metallurgical Systems.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.