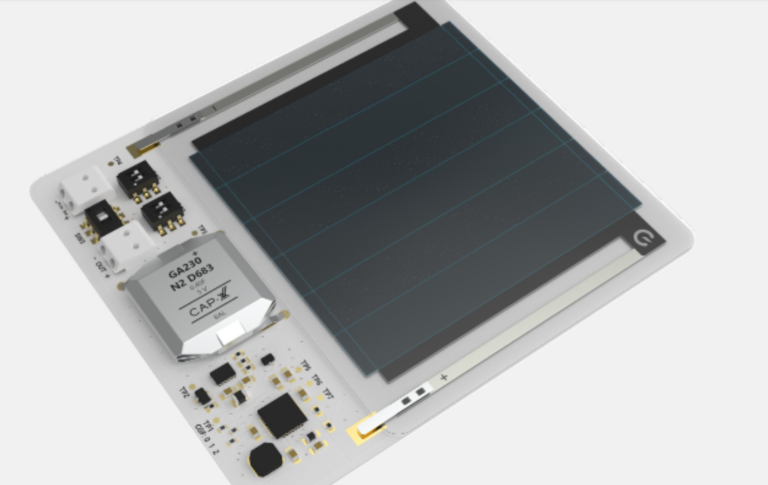

-based Epishine has launched a developer kit for the evaluation of its organic PV (OPV) technology, which it claims can replace or augment batteries in small indoor environmental sensing, information displays, and monitoring devices. The kit is targeted at innovators and original equipment manufacturers (OEM) considering embedding organic solar cells as a power source in new products.

Optimized for indoor lighting conditions and wireless low-power applications, the developer kit contains a supercapacitor, or energy buffer, that can be reconfigured to act as a battery, as well as embedded maximum power point tracking (MPPT) and a management system to handle charging, output voltages, and energy storage mechanisms.

“The evaluation kit highlights the power of Epishine’s indoor solar cells, demonstrating their ability to power low-power wireless devices. It combines our solar cells with a supercapacitor and allows for a fast replacement of primary batteries to evaluate light energy harvesting,” Jonas Bergqvist, CTO, Epishine told pv magazine.

The unit has sufficient current to support low-power data communications protocols, such Zigbee and LoRa, with output voltage ranging from 1.8 V to 3.3 V in 0.1 V steps, up to 300 mA output current, according to the company. It is purportedly safe for operation at -20C to 40C and a humidity range of 0 to 85%. Illumination intensity ranges from 20 lux to 1,000 lux.

The company claims that if the supercapacitor is empty, the circuit is able to start up with an input voltage of 38 mV. The maximum charge voltage of the capacitor is limited to 4.5 V.

Epishine recently subjected its LEH3_50x50_6_10 product to a lifecycle assessment (LCA) by Swedish environmental consultancy Miljögiraff and third-party reviewed by Sweco, a Stockholm-based engineering firm, resulting in a carbon footprint measurement of 0.86 g CO2eq/cm2.

The low carbon footprint is attributed in part to the company's patented production process, which avoids high temperatures and excludes certain materials. According to Bergqvist, it is cost-efficient too. “Roll to roll printing aligns well with these design rules with a very high degree of automation and comparably low process temperatures. Further, we have chosen to not use transparent conductive oxide electrodes, but all our solar cell layers are deposited from solution, thereby enabling a fully roll to roll printed solar cell with a high and very robust performance for indoor low light applications,” said Bergqvist.

Epishine offers customized cell sizes, supporting cut-outs in the cell surface, in sizes ranging from 20 cm2 to 300 cm2, to make the technology available to a wider range of sensor devices and internet of things (IoT) end nodes

In July, the six year old, company raised SEK 60 million ($5.43 million) in a round led by Jula Miljö & Energi, which belongs to Jula Holding, a diversified retail, real estate, and energy holding company based in Sweden, to fund product development and scaling up production in order to increase its market share in the indoor solar cell market.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.