A group of scientists from the Technical University of Denmark has fabricated a solar cell based on selenium by replacing thermal annealing with a new laser-annealing strategy.

“In our work, we investigated the potential of such a laser-annealing strategy specifically for selenium thin-film solar cells, and we report a new world record fill factor, a new world record ideality factor, and state-of-the-art device performance,” the research's lead author, Rasmus Nielsen, told pv magazine. “Moreover, the laser-annealing strategy enables us to control the morphology of the photoabsorber to an incredible extent.”

The proposed laser-annealing strategy consists of illuminating the selenium absorber through a semitransparent substrate, which the researchers said results in negligible surface roughness and larger grains. “The crystallization technique is particularly interesting, as it enables crystallizing the selenium absorber without heating up the substrate,” Nielsen also explained.

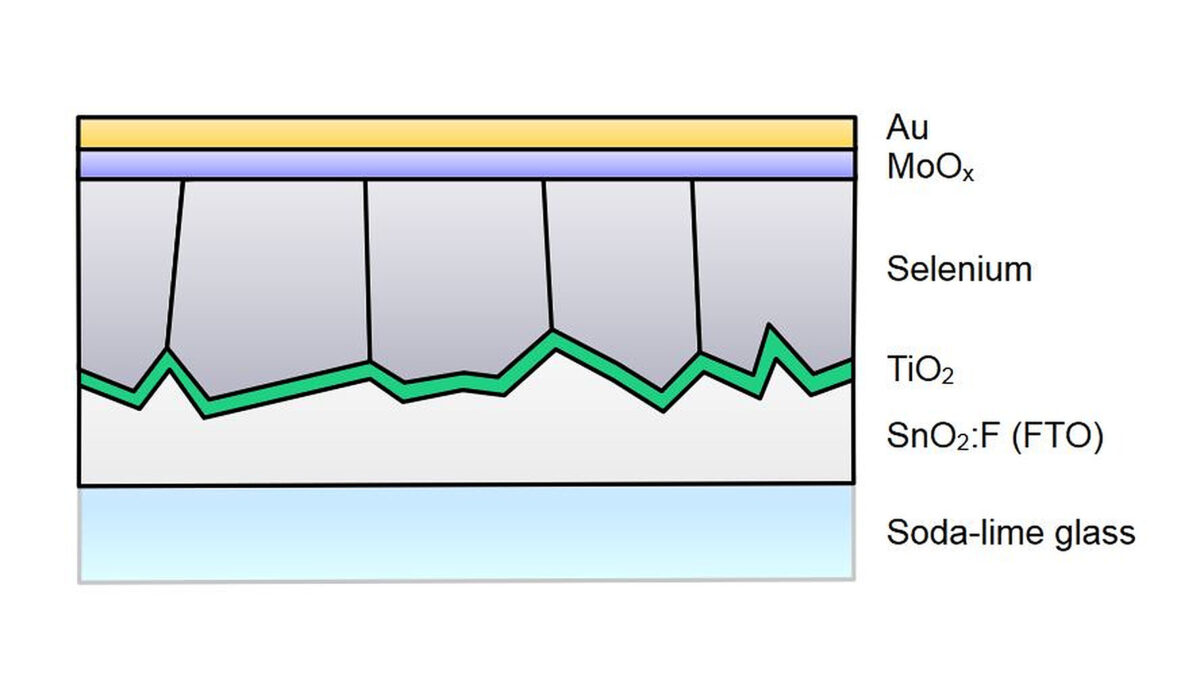

The group built the cell with a soda-lime glass substrate, a tin oxide (FTO) layer, an electron transport layer made of titanium oxide (TiO2), a selenium absorber, a molybdenum oxide (MoOx) layer, and a gold (Au) metal contact. The TiO2 thin film was formed by sputtering metallic Ti in a reactive atmosphere with an elevated substrate temperature of 400 C. The cell was then annealed at 500 C for 1 h under high vacuum.

“Laser-annealing of the amorphous selenium thin-film was performed through the substrate,” the academics explained. “Using this ‘superstrate' laser-annealing strategy, the optical energy is predominantly absorbed in the vicinity of the carrier separating junction

instead of the open surface from where selenium can re-evaporate away.”

Tested under standard illumination conditions, the cell achieved a power conversion efficiency of 5.0% and a record fill factor of 63.7%. The device also reached a record ideality factor value of n = 1.37. The ideality factor indicates the degree to which a solar cell resembles the characteristics of an ideal diode.

“It is worth noting that this fill factor value is the highest reported among selenium solar cells and that the fill factors of the laser-annealed samples reproducibly outperform those of the thermally annealed control samples, regardless of the range of laser doses investigated,” the scientists said. “The improved fill factor could be attributed to the more optimally aligned crystal grains and the flat surface morphology.”

The solar cell is described in the paper “Laser-Annealing and Solid-Phase Epitaxy of Selenium Thin-Film Solar Cells,” published in ACS Publications.

The same research group presented in December a 0.30 cm2 selenium solar cell with a world record open-circuit voltage of 0.99 V.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.