European funds have been pledged to back two solar and energy storage solutions to help smallholders in Africa till tough terrain and get produce to market. London-based impact investor InfraCo Africa will spend $2 million to acquire 40% of Mobility for Africa, a Harare business which adapts Chinese-made electric tricycles to bring mobility to remote areas of eastern Zimbabwe, and United Kingdom government body Innovate UK is funding a GBP 270,000 ($336,000) pilot project which could transform farming in Malawi.

US-born Mobility for Africa boss Shantha Bloemen tells pv magazine the accelerated roll-out of her company’s Hamba tricycles could have a huge impact on communities, and particularly on women who take produce to market.

“Africa is still primarily a rural continent, something like 70%, on average,” says Bloemen, who co-founded Mobility for Africa four years ago in Harare, alongside the late Felicity Tawengwa. “There’s a huge deficit of roads – concrete, tarred roads – and also a deficit of transport, and that becomes more acute the further you go away from a road. The World Bank says something like 40% of the rural population live at least 2 km from a major road.

“Even if you have a really good harvest and grow lots of tomatoes, it’s going to be very difficult to get those to market. Women die in childbirth because they can’t get to a rural health clinic, children are not vaccinated for the same reason. Women spend three hours walking to get water, that’s time that could be used to grow more tomatoes.

E-transport

“It’s something anyone who has spent time in rural parts of the continent can see,” adds Bloemen. “We have a romanticized view of women balancing big baskets or a baby on their heads and we’ve come to accept that as normal.”

Electric transport could change the picture, says Bloemen, who grew up in Australia and retains the accent.

She says, “The exciting thing is, now we have the potential of electric transport and we can’t justify ignoring such a lack of facilities any more. Petrol is often imported; it’s expensive, and it relies on a big company to distribute so it’s rarely available in rural areas in practical quantities. When we were reliant on fossil fuels [for transport] it was left as something that was impossible to solve.”

The Mobility for Africa director and CEO says she came up with the idea of importing tricycles – christened Hambas, from the Ndebele word for “go” – to Zimbabwe after seeing them widely used in China, where she worked for UNICEF, formerly known as the United Nations International Children’s Emergency Fund.

The tricycles are manufactured by Ducar and went electric, powered by a lead-acid battery, eight years ago.

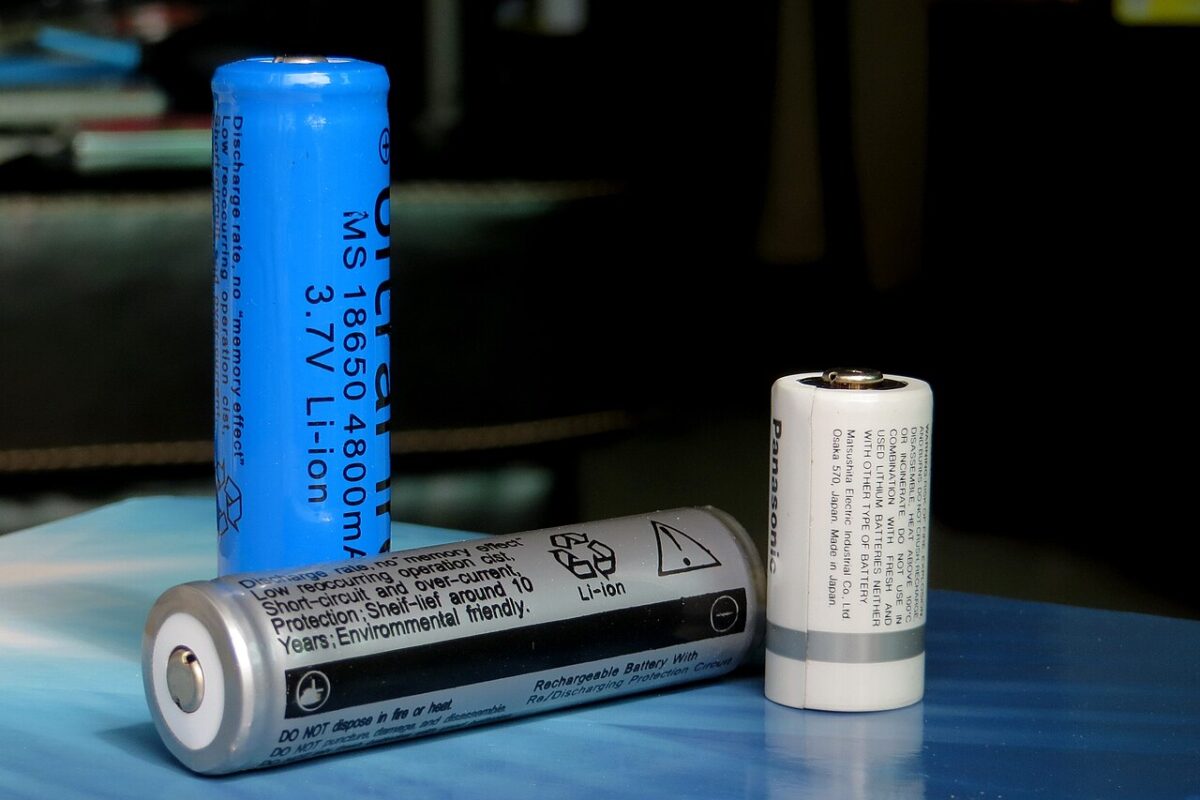

Mobility for Africa crowdfunded a container of 50 vehicles and deployed them with the help of students from China and Zimbabwe and two Ducar technicians. Assembling the Hambas locally, the company found the long charging times necessary meant lead-acid batteries were impractical. Although a consignment of off-the-shelf lithium-ion batteries brought further range, Bloemen says, “we could see they were more suited to [energy] storage than to transport.”

Bespoke batteries

Help arrived from former Tesla engineer Ruichen Zhao, whose Fourier Energy startup designed a bespoke 5 kW lithium phosphate battery which offers a 100 km-plus range under a 300 kg to 400 kg load. “It should last 8,000 to 10,000 cycles, which is something we’re testing – so that should be good for at least 40,000 km,” says Bloemen.

With the Hambas fit-for-purpose and modified to make them more comfortable for women to operate, Mobility for Africa needed an optimal deployment plan.

“We’ve been testing, for three years, a fleet management system for shared mobility,” says Bloemen. “Our model is based on introducing a fleet of tricycles designed for women, setting up a system of battery swapping, using off-grid energy, and you then use shared ownership models with groups of women renting the tricycles – now with, also, a lease-to-purchase model – on a monthly basis.

“We also have drivers servicing rural transport needs: transporting an elderly woman to a clinic, perhaps, or taking produce to market.”

Mobility for Africa tackles the recharging challenge by charging a fee to swap a battery. Additionally, it offers a “mobility-as-a-service” model, for groups to rent the tricycles on a monthly basis.

InfraCo cash

The $2 million equity investment from InfraCo Africa – which is funded by the governments of the Netherlands, Switzerland, and the UK – will turbocharge the number of Hambas and charging stations deployed by a company, which has locations at Harare and Domboshawa; a pilot site at Wedza, 140 km from Harare; and which set up a base, last year, at Chipinge, a mountainous dairy farming area 600 km from Harare.

With Mobility for Africa assembling four Hambas per day – Bloemen’s aim is to eventually have a factory in Zimbabwe. The company had a fleet of 200 vehicles at the time of writing and is due a further 200, spread evenly across its four sites, in August, and the same number again by March, to unlock the full InfraCo Africa investment. The intent is to fund 600 extra batteries, in addition to the Hambas, plus eight new solar-powered charging and battery swapping stations. Mobility for Africa’s [MFA] charging station at Wedza has 15 kW of rooftop solar generation capacity.

“MFA’s offering has the potential to deliver very high sustainable development impact, enabling increased trade in agricultural produce, creating employment, promoting economic growth, and easing movement in areas with difficult terrain,” an InfraCo spokesperson tells pv magazine.

Mobility for Africa is exploring how the charging stations and batteries which power the Hambas can offer electricity to rural communities, an aspect the project has in common with the AfTrak farming pilot scheme in regional neighbor Malawi.

Engineers from Loughborough University, in England, and US-based lead-acid industry body the Consortium for Battery Innovation (CBI) believe they have a sustainable method of providing the “deep bed farming” needed to cultivate the impermeable subsoil present in much of Malawi.

Project partner Tiyeni, a UK-based non-governmental organization, identified the increased agricultural yields available if small scale farmers could successfully till the “hard pan” ground that is around 300 mm below the topsoil in many areas of the African nation.

Loughborough University’s Jonathan Wilson and CBI representative and project manager Carl Telford came up with the idea of converting a hand-steered tractor unit to be powered by heavy, lead-acid truck batteries.

Eureka moment

“Jonathan Wilson and I went to Malawi with Innovate UK to learn about energy issues in the country,” says Telford. “We came up with the idea for the Aftrak.”

Taking its name from “Africa Tractor,” the AfTrak will feature four 12 V, 210 Ah batteries supplied by Swiss-owned manufacturer Clarios. Wilson tells pv magazine the AfTrak batteries will offer 6 kWh to 8 kWh of usable capacity.

The two tilling devices to be funded by the pilot program will be charged from a base station fitted with 3 kW of solar generation capacity which, Wilson says, will generate around 15 kWh to 18 kWh of clean power per day. Each AfTrak will also have a 200 W panel which will generate approximately 1 kWh daily, for top-up purposes. Clarios will donate the batteries for the first two AfTraks.

pv magazine print edition

The modular base stations feature 1 kW solar capacities which can be stacked to meet local needs and can provide clean energy for communities and function as a microgrid if needed, Wilson adds.

Project manager Telford says the AfTrak could find much wider use, citing neighboring Zambia, which has similar farming issues.

“If it proves successful, there could be other agricultural challenges we could use the basic system for, perhaps by changing the shape of the tilling tool. The part that does the tilling is typically made of a hard material so we’re making them replaceable with steel, and potentially with locally fabricated materials.”

Lead-acid

The CBI representative explains why the Aftrak features lead-acid, rather than lithium-ion batteries.

“Lead-acid batteries have a very high recycling rate,” says Telford, “by teaming up with Varta [German battery maker Vertrieb, Aufladung, Reparatur transportabler Akkumulatoren], the recycling rates of lead-acid batteries are incredible. The main thing is they’re so robust, so stable, and so easy to use – they’re abuse-tolerant. In the environment where we’re using them, they’re a better choice. They are also a lot cheaper than lithium-ion batteries.”

Mobility for Africa Chief Executive Bloemen also has high hopes for the wider use of her company’s electric Hambas, beyond rural Zimbabwe.

“Kenya and Zambia have similar ideas about community farming and agricultural development,” she says. “I do think this is a new focus in Africa because small-scale farmers are the backbone of African food production. If we can make the right strategic partnerships, we can come in and provide the mobility solutions.” Mobility for Africa’s pitch to InfraCo Africa cited potential markets in Benin, Malawi, Mozambique, Nigeria, and Zambia.

The company has already supplied vehicles to local police and health services.

“We’ve tested our tricycles with rural healthcare facilities and now we’re asking whether we can try a pilot program at, say, 50 clinics, especially when they’re already installing solar for cold-chain purposes,” says Bloemen.

She says the InfraCo Africa funding is a transformational development.

“We have been managing on grants,” she tells pv magazine. “$1.5 million of Swiss money, another grant of Swedish money but they all need matching funds. We were in what the startup community calls the ‘valley of death’ – where a company has to transition from family and friends – and crowdfunding – to really scaling. Two million dollars is a small-ticket item for InfraCo Africa but, for us, we now have a year to prove this can be financially viable and have a real impact and then, hopefully, we can grow to where I can put a proper factory in place and expand internationally.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

11 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.