Researchers at the Solar Energy Research Institute (SERI) of the Universiti Kebangsaan Malaysia have designed a prototype of a photovoltaic-thermal (PVT) system based on a nanoparticle-enhanced phase change material (Nano-PCM) and twisted absorber tubes.

The main goal of their work was to assess the absorber tube costs, working fluid choices, and Nano-PCM utilization, in an effort to investigate the economic viability of the system.

“The economic practicality of PVT collectors hinges on their ability to capture solar energy while remaining cost-effective and efficient,” the research’s corresponding author, Adnan Ibrahim, told pv magazine. “In our investigation, we thoroughly analyze PVT collectors' Annual Cost (AC) and Annual Energy Gain (AEG), using the AC/AEG ratio as a key cost-benefit indicator.”

PCMs are materials that can absorb, store, and release large amounts of latent heat over defined temperature ranges. They have often been used at the research level for PV module cooling and the storage of heat.

To create the Nano-PCM, the scientists combined a nanofluid based on silicon carbide (SiC) nanoparticles with water and paraffin. “The volume fractions of nanofluids were 0.3% and 0.6%, respectively, and the nano-PCM had a volume fraction of 1%,” they said, noting that SiC offers high heat conductivity, low cost, and stability.

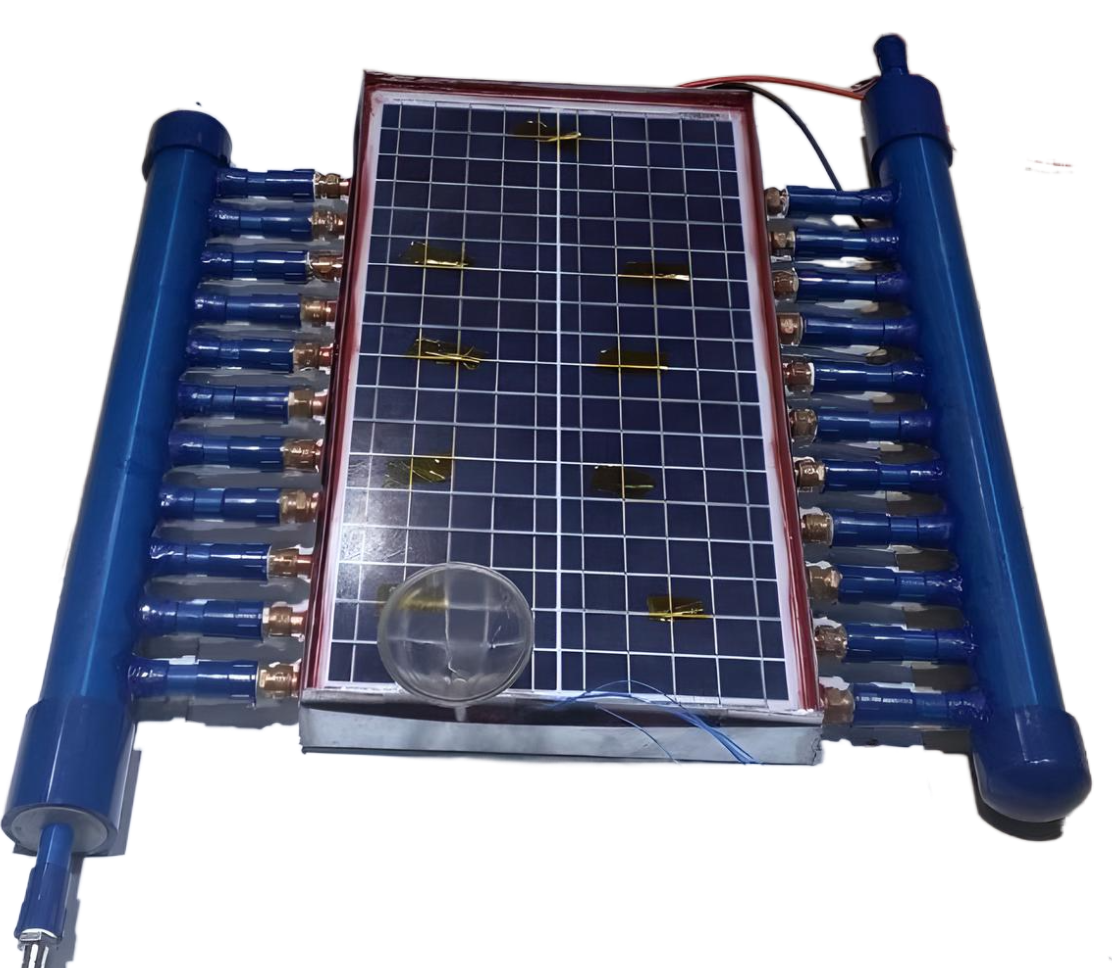

The PVT system consists of a 30 W photovoltaic module with a size of 64 cm x 30 cm, absorber tubes attached to the back of the panel via enhanced silicone glue bond, and a nano-PCM container surrounding the tubes. The setup also includes a fluid tank, heat exchanger, pumps, and a cooling unit.

The group tested the systems with different absorbers and working fluid configurations at a room temperature of 25 C, a working fluid temperature of 20 C and a solar irradiance level of 800 W/m2. It found that the panel has a surface temperature of 77.59 C, a PV efficiency of about 7%, and mass flow rates ranging from 0.008 to 0.04 kg/s.

“The thermal efficiency increased by 12% when the flow rate increased from 0.008 to 0.04 kg/s using the circular tube and by about 13.5% with the twisted tube,” the academics said. “This improvement was attributed to the increased convection heat transfer coefficient, resulting in a higher heat transfer rate between the PV panel and the absorber tubes.”

They also ascertained that using the twisted tube significantly reduced the temperature of the PV unit and that the prototype with a 0.6% concentration of SiC achieved thermal and photovoltaic efficiencies of 84.74% and 9.61%, respectively. “Its electrical output was 16 W, compared to 10.49 W for the bare PV panel,” they added.

“Our primary focus is optimizing the utilization of thermal and electrical energy from solar sources,” Ibrahim explained. “Interestingly, a standard PV panel's AC/AEG ratio was $0.0982/kWh. However, the most promising results were observed with a configuration incorporating nanofluids, twisted absorber tubes, and nano-PCM, achieving an impressive AC/AEG ratio of $0.0485/kWh.”

“Our research sheds valuable light on the potential of PVT systems, underscoring their role as a compelling avenue for sustainable energy solutions,” he emphasized.

The scientists introduced the system in the paper “Nanofluid-based photovoltaic thermal solar collector with nanoparticle-enhanced phase change material (Nano-PCM) and twisted absorber tubes,” published in Case Studies in Thermal Engineering.

“Further investigation opportunities for this field include utilizing twisted tape in twisted absorber tubes with PVT to enhance performance, exploring enhanced convection heat transfer coefficients, and investigating the application of twisted tubes in other absorber tube designs for potentially improved results,” they said, referring to the future directions their research should take.

Other research groups at the Universiti Kebangsaan Malaysia recently designed a bifacial photovoltaic-thermal (PVT) panel that utilizes circular jets impinging as a cooling medium, a photovoltaic-thermal system based on PCM cooling, multi-level fin heat sinks for solar module cooling, and passive technology for solar module cooling based on fin heat sinks.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.