Australian startup MGA Thermal said it has secured new funds to provide a foundation for the next phase of its growth. The funds will facilitate the commissioning of an automated production line at its factory in Tomago, New South Wales, accelerating operations well into 2024.

MGA CEO Erich Kisi said with the new production line – which will be capable of manufacturing more than 1 MWh of MGA Blocks every day – fast approaching completion, the latest round of investment will enable the company to strategically expand its commercial division and invest in engineering and implementation.

“With the imminent completion of our production line, we’re on track to produce 1,000 blocks per day which can then be assembled into 24/7 renewable energy storage,” he said.

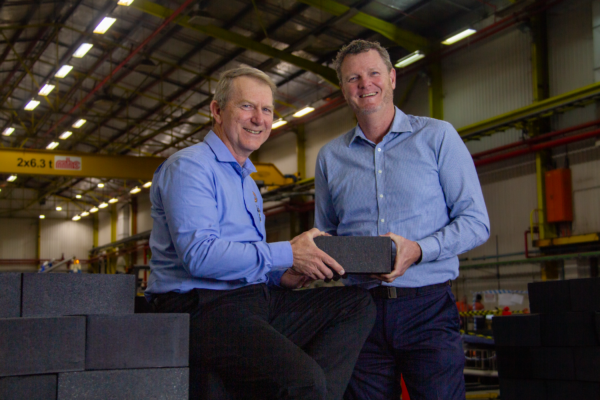

The company is commercializing a ‘miscibility gap alloy’ approach to thermal energy storage, storing heat in blocks made largely from aluminium and graphite and dispatching it to generate electricity.

MGA’s patented thermal energy storage blocks, about the size of a large house brick, consist of small alloy particles embedded within graphite-based blocks enclosed in a fully insulated system. Once heated the alloy particles can store heat for days with minimal energy loss. Heat exchangers are used to absorb heat from the blocks, with the heated gas or fluid suitable for industrial heat applications or to drive a steam turbine to generate electricity.

The company is in the final stages of commissioning a demonstration unit at its Tomago base that it said will provide a tangible example of the thermal energy storage system in action and substantiate its scalability for potential customers and partners.

MGA said the demonstration unit will include modular blocks stacked into large assemblies within MGA-designed thermal energy storage (TES) systems.

“These TES systems are able to store millions of kilowatt hours of energy in a cheaper and longer-lasting way compared to other dispatchable solutions,” the company said. “A stack of 3,700 blocks in our demonstration unit, about the size of a shipping container, stores enough energy to power more than 135 homes for 24 hours.”

Mark Croudace, MGA deputy CEO and chief commercial officer, said there is no shortage of demand for the company’s technology.

“Renewable energy sources come with their limitations, especially when the sun doesn’t shine and the wind doesn’t blow,” he said. “Plugging this gap is the reason we exist. MGA Technology is perfectly aligned to generate 24/7 clean steam for harder-to-abate industrial sectors, a rapidly growing very large market domestically and globally.”

The latest funding round attracted support from existing investors including Main Sequence, Varley Holdings, Melt Ventures and New Zealand’s Climate Venture Capital Fund while Understorey Ventures and Australian advisory firm Pollination Group have signed on as new investors.

Pollination CEO Martijn Wilder said MGA’s technology has enormous potential to support the uptake of clean energy in Australia.

“The energy transition for the country’s heavy industry to clean energy is a huge challenge and one that requires us to rethink the way we store energy,” he said. “MGA Thermal provides on-demand zero carbon heat which can decarbonise many industrial uses as well as provide clean electricity generation.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Looks like a great product for Northern European markets such as Denmark and Sweden with high wind power penetration and large district heating networks. Such networks in some cases have large scale thermal storage in the form of hot water, and this system would allow steam turbines to run from stored high temperature heat in CHP mode storing any excess low temperature heat in hot water buffer tanks for district heating. The same could apply in Scotland with the systems located at distilleries and breweries – helping to reduce wind power curtailment.

I dont see any significant market for this in northern Europe. Storing electricity from wind in this for later steam production just seems so incredible inefficient. There is almost no information to go by from this article, but just on the napkin calculation suggests this will be at best a niche tech for very specific situations where other, more efficient storage tech is not feasible. Making steam with electricity is just too expensive in most cases. never mind building an expensive storage to go with it.

There are plenty of biomass co-production plants already available, situated next to large steam consumers and district heating. It’s a mature and reliable technology that will be hard to beat or supplement with this storage tech.