Stellantis, Saft and CNRS have developed a prototype IBIS energy storage battery in a joint corporate research project in France. The project team intends to make the technology commercially available in Stellantis vehicles before the end of this decade.

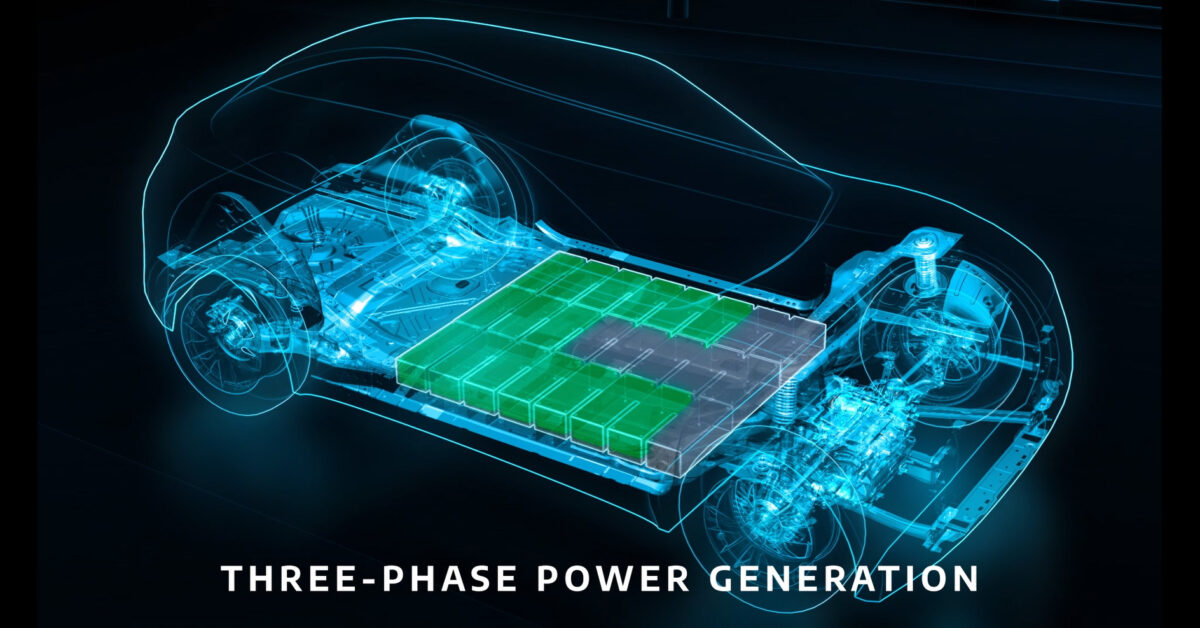

According to the project partners, this integration of the inverter and charging functions enables a more efficient and less expensive energy storage system, which enhances the range and takes less space in the vehicle.

“The IBIS project offers the opportunity to reduce vehicle weight and the cost of EV powertrain and vehicle manufacturing, while offering a large number of new features,” the partners said.

IBIS integrates electronic conversion cards that perform the electric charger and inverter functions and are installed as close as possible to the lithium-ion battery cells. Its control system makes it possible to feed AC power directly to the battery and enables AC current for the electric motor to be produced directly from the IBIS.

A demonstrator has been in operation since last summer. According to the project partners, this system is “the subject of numerous patents and marks a major break from electrical energy conversion systems currently used.”

The demo project has been a testing field for a variety of technical concepts and control and operating functions in preparation for automotive and stationary applications.

The IBIS project partners are now focused on building a fully functional prototype vehicle, which will be tested on Stellantis development benches and test tracts as well as on open roads.

In the field of stationary energy storage and renewable energy integration, the IBIS technology will enable Saft to offer “turnkey installations with improved battery availability, optimized use of installed energy and a smaller footprint.” The intrinsic architecture of the IBIS battery will allow for simplified maintenance and upgrade, according to the project partners.

The IBIS project is funded by the Future Investment Plan, administered by the French Environment and Energy Management Agency (ADEME) and coordinated by Stellantis.

Saft, E2CAD and Sherpa Engineering are involved as industrial partners on the project, alongside the CNRS research laboratories GeePs, SATIE, LEPMI, and Institut Lafayette.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.