Belgian research institute Imec has developed an inverted perovskite solar cell with reduced nonradiative recombination and improved interfacial contact.

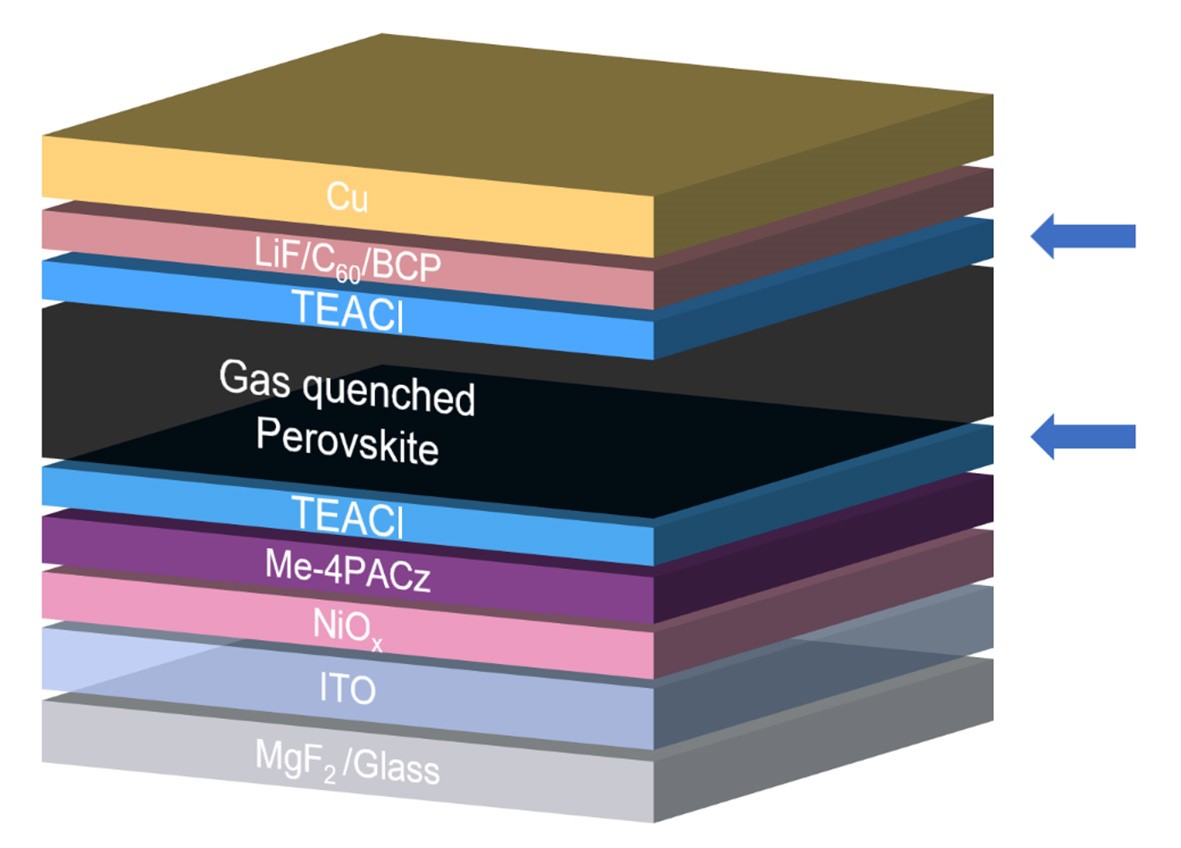

The cell has a p-i-n structure, which means the perovskite cell material is deposited onto the hole transport layer, and then coated with the electron transport layer – the opposite way round to conventional n-i-p device architecture. Inverted perovskite solar cells typically show strong stability, but have lagged behind conventional devices in terms of conversion efficiency and cell performance.

The device also utilizes an “upper” interface between the perovskite and the buckminsterfullerene (C60) electron transport layer and a “lower” interface between the perovskite and the hole transport layer made of nickel(II) oxide (NiOx). Both interfaces were treated with an ammonium salt known as 2-thiopheneethylammonium chloride (TEACl). The results were compared.

The scientists said the dual-layer treatment resulted in enhanced efficiency, with a relative power conversion efficiency (PCE) increase of 9% compared to a reference non-treated device.

“Optimization of these interfaces can consequently minimize losses and improve energy extraction, resulting in increased device efficiency and operational stability,” stated the researchers, noting that this architecture creates a 2D perovskite layer at the interface. Cells with this configuration usually exhibit large exciton binding energies and are generally more stable than conventional 3D devices due to the protection provided by the organic ligands.

Described in full in the paper “Minimizing the Interface-Driven Losses in Inverted Perovskite Solar Cells and Modules,” published in ACS Energy Letters, the cell achieved a power conversion efficiency of 24.3%, an open-circuit voltage of 1.17 V, short-circuit density of 24.5 mA/cm2, and a fill factor of 84.6%.

“Besides the increase in efficiency, we also observed a remarkable stability,” stated Tom Aernouts, R&D manager of the Thin-Film Photovoltaics team. “Indeed, after 1,000 h of continuous operation under one-sun illumination, the devices showed a 97% retention of performance, which is among the current bests.”

The group also found that the cell retained 88% of its initial performance after 1,850 h, compared to 55% in non-treated cells.

The academics also used the cells to fabricate a mini module of 3.63 cm2 that achieved an efficiency of 22.6% and a fill factor of 82.4%. “However, commercialization of such applications requires industry-compatible processing techniques, which overcome current stability issues, amongst others,” they specified.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.