A research team at Estonia's Tallinn University of Technology (TalTech) has developed a solar cell based on bismuth trisulfide (Bi2S3) using close-spaced sublimation (CSS), which is a physical vapor deposition that is commonly applied in cadmium telluride (CdTe) thin-film solar cells.

Bi2S3 is a promising candidate for the photovoltaic community owing to the earth-abundant and environmentally friendly constituent elements alongside appropriate optoelectronic properties, such as a desirable band gap of around 1.2 eV, a large absorption coefficient of around 105 cm–1, and long-term stability.

“In our work, for the first time, a proof of concept solar cell with CSS Bi2S3 was demonstrated and an in-depth analysis of the interrelation between grain structure, interface recombination, and device performance was provided,” the research's lead author, Mykhailo Koltsov, told pv magazine. “Employing low-temperature dependence photoluminescence (PL), we provided in premiere new and complementary insights on possible defects and recombination mechanisms in green and earth-abundant Bi2S3 PV material.”

The scientists initially developed several Bi2S3 absorber films deposited on various substrates. Via scanning electron microscopy (SEM) they then investigated their properties and morphology, in order to identify those with optimal growth.

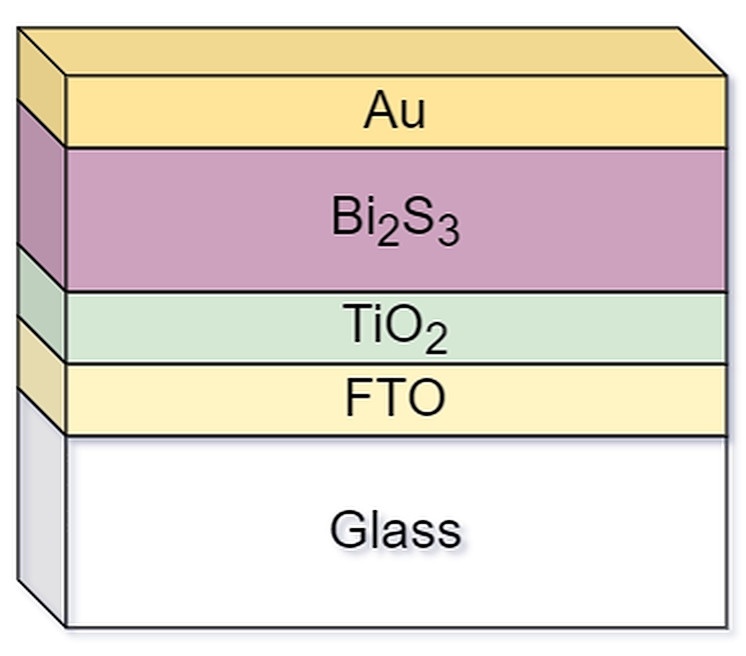

With the best Bi2S3 absorber film, the scientists built a cell based on a substrate made of glass and fluorine-doped tin oxide (FTO), electron transport layer (ETL) using either a titanium oxide (TiO2), the Bi2S3 absorber itself, and gold (Au) metal contacts. The Bi2S3 absorber was deposited at 450 C. They also constructed a similar device relying on an ETL based on cadmium sulfide (CdS).

The first cell achieved a power conversion efficiency of 0.1%, an open-circuit voltage of 10 mV, a short-circuit current of 3.5 mA/cm2, and a fill factor of 23.0. The second device reached an efficiency of 0.3%, an open-circuit voltage of 190 mV, a short-circuit current of 4.6 mA/cm2, and a fill factor of 32.0.

“For both device configurations, processed with Bi2S3 at CSS substrate temperatures below 400 ◦C, the efficiencies tend to be zero,” the researchers stated. “The source temperature of 550 C and substrate temperature of 400–450 C were identified as optimal temperatures which allowed a reasonable deposition rate and fabrication of uniform Bi2S3 films.”

According to Koltsov, the development of Bi2S3 PV technology would mean lower processing temperatures and reduced time compared to state-of-the-art thin-film industrial technologies, particularly the use of thinner absorbers deposited using single-step processes.

“This delivers a relevant reduction in the power requirements for fabrication, ensuring a lower CO2 footprint and environmental impact,” he went on to say. “Environmental impact is also reduced by the absence of toxic or hazardous materials in the fabrication process.”

The potential for reduction of power production costs can be understood by consideration of compatibility with established thin-film CdTe technology. Existing infrastructure could be utilized to reduce the CdTe module cost per watt for equivalent efficiency.

“Cadmium and telluride currently cost around $3.3/kg and $70/kg, respectively,” he said. “Bismuth and sulfur – the two compounds forming Bi2S3 P – currently costs $8.6/kg and up to 0.5/kg, respectively. Furthermore, the Bi2S3 absorber is less than 1μm thick while CdTe absorber have usually thickness of 2μm.”

Koltsov believes the Bi2S3 technology has the potential for reduction of PV electricity price, targeting production costs of less than €0.20 ($0.224)/W.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.