The Swiss Center for Electronics and Microtechnology (CSEM) and the École polytechnique fédérale de Lausanne (EPFL) announced in June 2022 they achieved a power conversion efficiency of 31.25% for a 1 cm2 tandem perovskite-silicon solar cell, which they said represented, at the time, a world record for a PV device of this kind.

The two scientific institutions, however, did not release many details about the cell technology and how the new record was made possible. Now, more than one year later, they presented the cell and the related manufacturing processes in the paper “Interface passivation for 31.25%-efficient perovskite/silicon tandem solar cells,” which was published last week in Science.

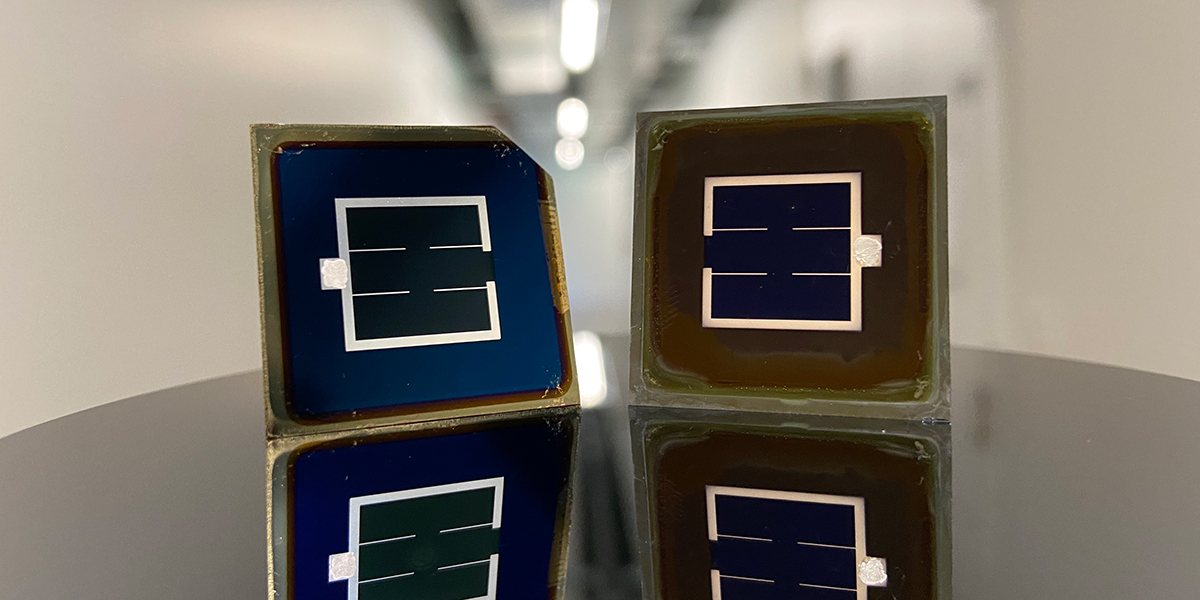

“Our team took a pioneering approach by designing a tandem solar cell with a perovskite layer conformally coated on a silicon bottom cell,” the research's lead author, Xin-Yu Chin, told pv magazine. “The silicon bottom cell featured micrometric pyramids, an industry-standard modification that enhances its photocurrent generation.”

One of the key challenges in perovskite/silicon tandem cells is the recombination losses occurring at the perovskite top surface interfacing with the electron selective contact. Recombination is a process where the photogenerated charge carriers – electrons and holes – recombine before they can be collected and utilized to produce electricity, which leads to efficiency losses. “To address this issue, we incorporated an additive into the processing sequence, which proved instrumental in regulating the perovskite crystallization process,” Chin explained. “This step efficiently passivated the interface, effectively mitigating recombination losses that hamper overall cell performance.”

The scientists used a phosphonic acid known as 2,3,4,5,6-Pentafluorobenzylphosphonic acid (FBPAc) to passivate the perovskite absorber and another phosphonic acid called methyl-substituted carbazole (Me-4PACz) to obtain passivated interfacial defects in the hole transport layer (HTL).

The cell is based on a substrate made of glass and indium tin oxide (ITO), a Me-4PACz HTL, an absorber made with the FABr:FAI perovskite with an energy bandgap of 1.70 eV, a buckminsterfullerene (C60) electron transport layer, a bathocuproine (BCP) buffer layer, and a top electrode based on copper (Cu).

Tested under standard illumination conditions, the device showed an efficiency of 31.25%, an open-circuit voltage of 1.91 V, a short-circuit current of 20.47 mA/cm2, and a fill factor of 79.8%, which were all certified by the US Department of Energy's National Renewable Energy Laboratory (NREL).

“The use of Me-4PACz reduces voltage losses at the perovskite/HTL interface, whereas the inclusion of FBPAc in the perovskite deposition sequence reduces the voltage losses at the perovskite/C 60 ETL interface and leads to more favorable perovskite microstructures with larger domains,” the researchers emphasized, adding that the outcome also indicates that the technology is prepared to advance to the subsequent stage of its development, which necessitates a central focus on stability and scalability aspects.

“It is probable that the technology will still require 5 to 10 years to enter the market. Existing industrial solutions are already applicable to all the thin-film materials used in the tandem solar cell, as exemplified by Oxford PV's recent results,” Chin added. “The primary concern that the scientific community must address is the stability of the perovskite material. Can these materials be rendered stable enough to endure over 20 years in practical applications? This is the pivotal question that will determine the commercial success and impact of this technology.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This is not useful news anymore!

Record efficiencies are not useful anymore. Stability records are what is needed now. When will researchers please just focus on this metric and ignore ever higher 30%+ efficiencies.