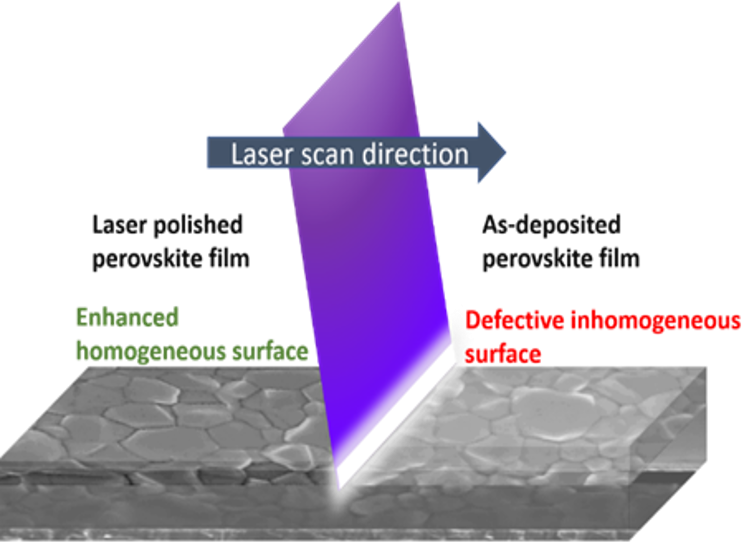

A European research team has sought the improve performance and efficiency of a perovskite solar cell by passivating surface defects in the perovskite film via commercial laser treatment.

“Our work is a proof of concept, and we are consistently working on advanced results,” corresponding co-author Monika Rai, told pv magazine, noting that the proposed approach is solvent-free and industrially scalable.

They used an industrial nanosecond pulsed ultraviolet (UV) laser at two different energy intensities of 160 nJ and 650 nJ, respectively.

They then utilize scanning electron microscopy (SEM) and X-ray diffraction (XRD) measurements to evaluate the effect of the laser pulse on the morphology of the film and found that both intensities result in a uniform grain size distribution and clear grain boundaries, although the higher intensity also showed some degraded perovskite grains.

By contrast, the laser pulse with the lower intensity did not damage the perovskite surface or affected any bulk properties of the perovskite thin film. “There is no observable difference in the binding energy or broadening of the spectra at the low laser energy, which suggests a negligible change in the chemical properties at the perovskite surface,” the researchers said. “At high laser energy, the overall absorption decreases due to obvious destruction in the film, as supported by XRD and SEM measurements.”

The team applied the treatment to a solar cell based on triple-cation cesium methylammonium formamidinium (CsMAFA) and found its efficiency grew from 18.0% to 19.3%, with the stability performance being also improved. “At optimized energy, the laser-polished devices show improved open-circuit voltage (VoC) and fill factor, owing to reduced interface recombination losses, unlocking the potential of high Voc from the perovskites of similar bandgaps,” they said, adding that the cell achieved a remarkable Voc of 1.21 V.

The cell was able to retain around 90% of its initial efficiency for 1,000 h compared to 75% for a reference device to which the laser treatment was not applied.

“This technique may be particularly suitable for roll-to-roll (R2R) production lines,” co-author Micahel Saliba told pv magazine.

Details on the approach, the laser power fine-tuning, and the measurement methods are documented in “Light Makes Right: Laser Polishing for Surface Modification of Perovskite Solar Cells,” published in ACS Energy Letters. The research group includes scientists from the University of Stuttgart and the Brandenburg University of Technology Cottbus–Senftenberg in Germany, the University of Luxembourg, and the University of Valencia in Spain.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.