Making components that can withstand being installed outdoors for years and even decades, in any type of climate, while maintaining at least the vast majority of their initial performance, is a key goal for the solar industry.

There has been plenty of progress, with both technological improvements and competition between manufacturers driving longer product and performance warranties, and therefore longer contracts for the sale of electricity from a solar project. Most manufacturers now offer 30-year warranties guaranteeing at least 80% of the modules’ initial performance, and one has even extended this to 40 years.

But for solar installations many regions are targeting, for 2050 and beyond, even longer lifetimes are needed, especially for installations located in harsh climate regions whether due to heat, cold, moisture, dust or other conditions. And this will mean understanding exactly how PV modules tend to degrade under these conditions.

Scientists led by the University of Agder in Norway decided to focus on degradation caused by moisture – this being a main characteristic of the climate in Grimstad where the university is based.

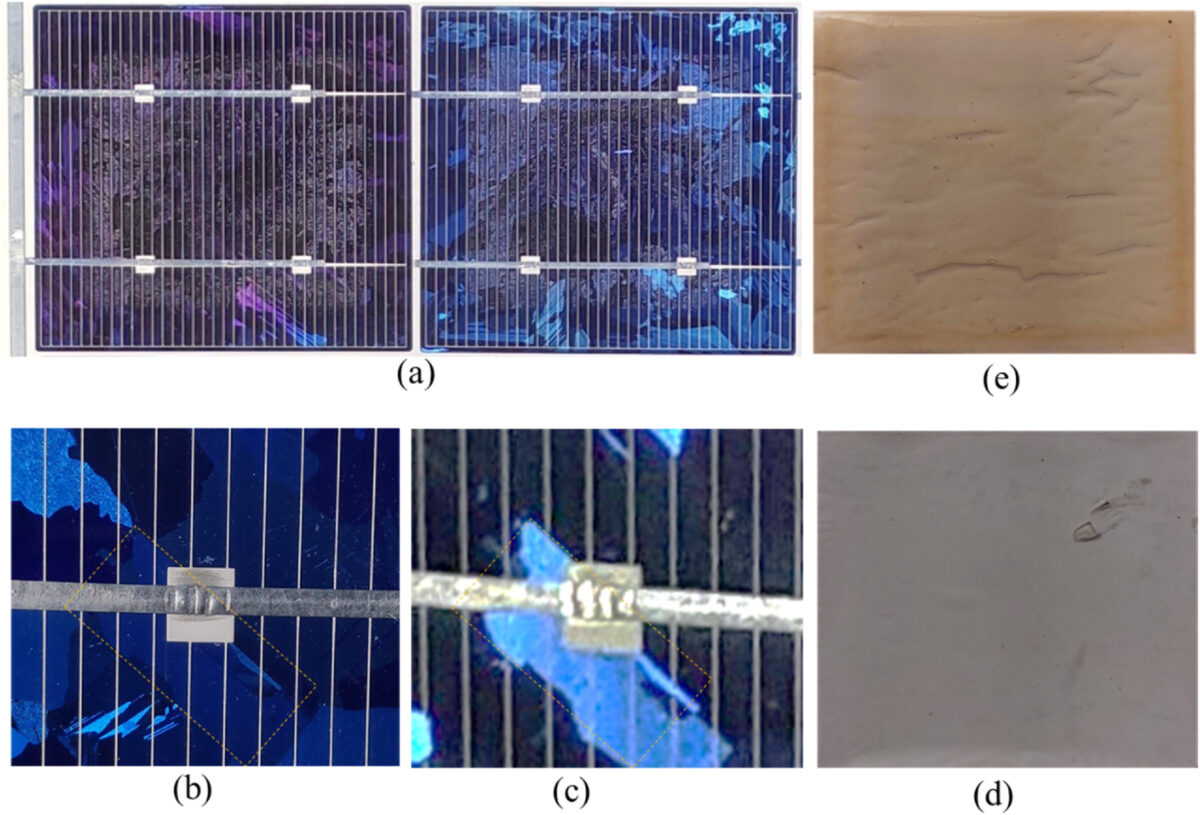

The group took modules from a decommissioned PV array installed in the town in 2000 and used a range of techniques, both non-destructive and destructive, to examine the inner workings of the modules, and how various components had fared over years in the field.

Their results are described in full in the paper “Moisture induced degradation in field-aged multicrystalline silicon photovoltaic modules,” published in Solar Energy Materials and Solar Cells. The study found moisture ingress had driven degradation of the encapsulant, producing acetic acid and various substances that drive corrosion and other forms of degradation to the silicon cells. Moisture was also found to have a major role in corrosion at solder joints – causing lead to corrosion rather than “sacrificial” tin included in the solder.

The scientists behind the work accepted that PV materials and manufacturing processes have moved on greatly since the modules in this study were manufactured more than 20 years ago. However, while accelerated testing is useful, they say that studying field-aged modules is still necessary, and that many mechanisms revealed in this study are still relevant to modules rolling off production lines today.

“Though solar PV module materials and technology have evolved over the years, MID mechanisms in solar PV modules appear to follow a similar trend,” they state in the paper. “Hence, insights from this work can guide decision making at the present and in the future as regards understanding the performance reliability of solar PV plants.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.